In the world of piping, plumbing, construction, and manufacturing, pipe threads are an essential element that holds everything together, quite literally. These unassuming yet crucial components play a pivotal role in ensuring leak-free connections, structural integrity, and efficient fluid transport. In this comprehensive guide, we’ll dive deep into the world of pipe threads, exploring their types, applications, standards, and best practices.

What is a Pipe Thread?

Pipe threads are helical ridges carved onto the outer surface of a pipe or fitting, designed to create a secure connection between two components. These threads serve two primary purposes:

- to facilitate the assembly and disassembly of pipes or fittings and

- to create a seal that prevents leaks.

A variety of screw thread variations have developed to cater to fastening and hydraulic systems. The careful selection of the appropriate screw thread plays a vital role in establishing a seal that is impervious to leaks.

Types of Pipe Threads

Pipe threads come in various designs, each tailored to specific needs. Broadly, there are four major types of pipe threads:

1. American National Pipe Thread:

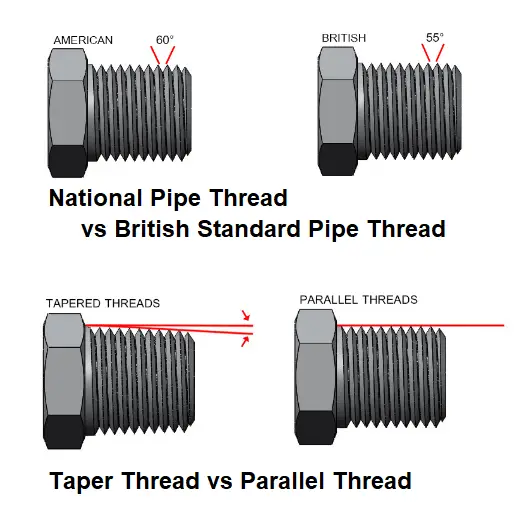

The American National Pipe (Also Known as National Pipe Thread) Thread is a widely used thread standard in the United States for screw threads used on threaded pipes and pipe fittings. This encompasses both tapered and straight thread series designed to fulfill diverse requirements, such as enhancing stability, ensuring pressure-tight seals, or accomplishing both objectives simultaneously. These classifications are denoted by complete names alongside abbreviations like NPT, NPS, NPTF, or NPSC. The National Pipe Thread series have the 60° included angle.

Types of American National Pipe Threads:

The various types of American National Pipe Threads or National Pipe Threads are as follows:

| Abbreviated Pipe Thread Form | Expanded Pipe Thread form | Full name | Remarks/Comment |

| NPT | National pipe taper | American National Standard Taper Pipe Thread | Tapered for sealing, often without any thread sealant; for connections in nearly every type of service |

| NPS | National pipe straight | American National Standard Straight Pipe Thread | For rigidity; sealable only with sealant; sometimes male straight is mated with female tapered for low-pressure sealing. NPS threads are used when a seal is not required but a mechanical connection is desired. |

| NPSC | National pipe straight–coupling | American National Standard Straight Pipe Thread for Couplings | For general couplings |

| NPSF | National pipe straight–fuel and oil | Dryseal USA (American) Standard Fuel Internal Straight Pipe Thread | Internal only, straight |

| NPSH | National pipe straight–hose | American National Standard Straight Pipe Thread for Hose Couplings | For hose couplings |

| NPSI | National pipe straight–intermediate | Dryseal USA (American) Standard Intermediate Internal Straight Pipe Thread | Similar to NPSF but slightly larger; internal only, straight |

| NPSL | National pipe straight–locknut | American National Standard Straight Pipe Thread for Loose-fitting Mechanical Joints with Locknuts | For use with locknuts |

| NPSM | National pipe straight–mechanical | American National Standard Straight Pipe Thread for Free-fitting Mechanical Joints | For various rigid mechanical uses |

| NPTF | National pipe taper–fuel and oil | Dryseal USA (American) Standard Taper Pipe Thread | For dry seal connections in nearly every type of service, especially fuel connections |

| NPTR | National pipe taper–railing | American National Standard Taper Pipe Thread for Railing Joints | For railings |

| PTF-SAE SHORT | Pipe taper, fuel, SAE, short | Dryseal SAE Short Taper Pipe Thread | Named after SAE International; similar to NPTF but one turn shorter |

2. BSP (British Standard Pipe Thread):

Common in the UK and many parts of the world, BSP pipe threads are also adopted internationally for interconnecting and sealing pipes and fittings providing reliable sealing capabilities. There are two types of distinguished BSP pipe threads:

- BSPT: British Standard Pipe Taper thread (BSPT), whose diameter increases or decreases along the length of the thread; and

- BSPP (British Standard Pipe Parallel): Unlike tapered threads, BSPP threads are parallel, ensuring a consistent diameter along the thread length. They are often used in low-pressure applications.

The Thread form in BSP pipe thread types follows the British Standard Whitworth standard with the symmetrical V-thread in which the angle between the flanks is 55° (measured in an axial plane)

3. ISO Metric Thread:

The ISO Metric Thread is a standardized system for screw threads, established by the International Organization for Standardization (ISO). This thread standard is widely used globally, especially in countries that have adopted the metric system of measurement. ISO Metric Threads are designed to facilitate precise and interchangeable connections between threaded components, ensuring compatibility across various applications and industries.

Key characteristics of ISO Metric Threads include:

- Metric Measurement: ISO Metric Threads are defined using metric units, such as millimeters for thread diameter and pitch. This allows for consistent and standardized measurements, making it easier to select the right threads for specific applications.

- Thread Classes: ISO Metric Threads come in different classes that define the level of tolerance and fit between mating threads. The most common thread classes are “fine” and “coarse,” with variations like “extra fine” also available for specific applications.

- Thread Direction: ISO Metric Threads typically have a right-hand thread direction, meaning they are tightened by turning clockwise. Left-hand threads are less common but can be found in specialized applications.

- Applications: ISO Metric Threads find extensive use in industries like manufacturing, automotive, machinery, and construction. They are employed for various purposes, including fastening, joining, and assembling components.

- Variants: ISO Metric Threads encompass a range of thread types, such as ISO metric coarse thread (M), ISO metric fine thread (MF), and ISO metric extra fine thread (MFEF). Each variant is suited for different applications based on factors like load-bearing capacity and fastening requirements.

The adoption of ISO Metric Threads has facilitated international standardization and eased the process of sourcing, manufacturing, and maintaining threaded components. By adhering to ISO Metric Thread specifications, industries can benefit from improved compatibility, reduced errors, and increased efficiency in their operations.

4. Unified Screw Threads:

Unified Screw Thread, often referred to simply as Unified Thread, is a standard system of screw threads that was developed in the United States. It is used for a wide range of applications across industries, providing a consistent and interchangeable thread design for various fastening and assembly purposes. The Unified Thread system was established to streamline the previously fragmented thread standards in the U.S. and promote compatibility between different components.

Key features of Unified Screw Threads include:

- Inch Measurement: Unified Thread uses inch-based measurements for thread diameter, pitch, and other thread parameters. This makes it particularly relevant in countries where the imperial system is used.

- Thread Classes: Unified Thread comes in different classes that define the level of tolerance and fit between mating threads. Common classes include “Unified Coarse” (UNC) and “Unified Fine” (UNF).

- Thread Direction: Unified Threads typically have a right-hand thread direction, meaning they are tightened by turning clockwise. Left-hand threads are less common but are used in specialized applications.

- Applications: Unified Threads are widely used in various industries, including manufacturing, automotive, aerospace, construction, and more. They are suitable for fastening, joining, and assembling components, ensuring reliable connections.

- Variants: Unified Thread offers several variations, such as Unified Extra Fine (UNEF) threads for applications requiring higher thread density or finer adjustments.

The Unified Screw Thread system has significantly simplified the process of selecting and using threaded components, promoting interchangeability and reducing confusion that could arise from different thread standards. By adhering to the Unified Thread specifications, industries can benefit from improved compatibility, reduced manufacturing costs, and increased efficiency in assembling products and structures.

Parts of a Pipe Thread: Pipe Thread Nomenclature

Pipe threads consist of several key components that work together to create a secure and leak-free connection between pipes and fittings. Understanding these components is essential for proper assembly and maintenance. Here are the main parts of a pipe thread:

- Thread Crest: The thread crest is the topmost point of the helical ridge on a male thread. It’s the highest point of the thread profile.

- Thread Root: The thread root is the bottommost point of the helical groove on a female thread. It’s the lowest point of the thread profile.

- Thread Flank: The thread flank is the sloping surface between the thread crest and the thread root. Threads have two flanks, an upper flank, and a lower flank, which meet at the thread crest.

- Thread Pitch: The thread pitch is the distance between two consecutive thread crests or roots. It determines how tightly the threads fit together and affects the ease of assembly and disassembly.

- Thread Angle: The thread angle is the angle between the flanks of the thread. Different thread standards have different thread angles; for example, the thread angle for NPT threads is 60 degrees.

- Taper: Tapered threads, like NPT and BSPT, have a gradual change in diameter over the length of the thread. This taper helps create a tight seal as the threads are tightened.

- Thread Length: The thread length refers to the portion of the pipe or fitting that is threaded. It determines how much engagement there is between the male and female threads when connected.

- Thread Direction: Threads can be right-handed or left-handed. In most applications, right-handed threads are used, meaning they are tightened by turning clockwise. Left-handed threads are less common and are tightened by turning counterclockwise.

- Thread Relief: The thread relief is a flat surface at the end of a threaded section that provides clearance for the engagement of threads and prevents them from bottoming out prematurely.

- Thread Engagement: Thread engagement refers to the depth to which male and female threads interact when connected. Sufficient thread engagement is important for achieving a strong and secure connection.

- Thread Seal: Threaded connections often require a sealant to ensure a leak-free joint. Thread sealants, such as Teflon tape or pipe dope, are applied to the male threads to enhance sealing properties.

- Thread Identification: Threads are often identified using specific markings, such as size, pitch, and type. These markings help ensure the proper matching of threads during assembly.

Applications and Industries

Pipe threads find applications across a wide range of industries, including:

- Plumbing: Connecting pipes and fittings in residential, commercial, and industrial plumbing systems.

- Oil and Gas: Facilitating the transportation of fluids in pipelines and well systems.

- Manufacturing: Assembling machinery and equipment that involve fluid flow.

- Chemical Processing: Ensuring leak-free connections for the transfer of hazardous chemicals.

- Fire Protection: Creating connections for sprinkler systems in buildings.

Standards and Regulations

To ensure compatibility and safety, various organizations have established standards for pipe threads:

- ASME B1.20.1: This standard covers pipe threads, including NPT, NPS, and NPSM threads, used in the United States.

- ISO 7-1: Pertinent to BSPT and BSPP threads, this ISO standard is prevalent in Europe and other metric-centric regions.

- ISO 724: General Purpose Metri Screw Threads

- ASME B1.1: Unified Inch Screw Threads

Best Practices for Working with Pipe Threads

- Proper Thread Engagement: Ensure sufficient thread engagement for a secure connection. Incomplete engagement can result in weak joints and leaks.

- Use of Thread Sealants: Depending on the application and thread type, thread sealants like Teflon tape or pipe dope can enhance sealing properties.

- Avoid Over-Tightening: Excessive force can damage threads, leading to leaks or stripped threads. Follow manufacturer recommendations for torque values.

- Regular Inspection: Periodic checks for wear, corrosion, or damage are essential to maintaining the integrity of pipe threads.

Differences Between NPT and BSP Threads

Here’s a comparison table outlining the key differences between NPT (National Pipe Thread) and BSP (British Standard Pipe) threads:

| Aspect | NPT (National Pipe Thread) | BSP (British Standard Pipe) |

|---|---|---|

| Thread Type | Tapered | Parallel |

| Thread Angle | 60 degrees | 55 degrees (BSPP), 60 degrees (BSPT) |

| Sealing Mechanism | Tapered design aids in sealing | Sealing is achieved through an O-ring or gasket |

| Common Applications | General piping and plumbing (US) | Piping and Plumbing (UK and some other countries) |

| Usage | Widely used in the United States | Prevalent in the UK and Europe |

| Thread Names and Abbreviations | NPT (National Pipe Thread), NPTF (National Pipe Thread Fuel), NPS (National Pipe Straight), NPSM (National Pipe Straight Mechanical) | BSPP (British Standard Pipe Parallel), BSPT (British Standard Pipe Tapered) |

| Compatibility with Each Other | Not interchangeable with BSPP or BSPT threads | Not interchangeable with NPT threads |

The differences between the NPT and BST thread pitch dimensions are provided below:

| Pipe Thread Sizes | Pitch (Threads per Inch) | |

|---|---|---|

| NPT/NPS | BSP | |

| 1/8 | 27 | 28 |

| 1/4 | 18 | 19 |

| 3/8 | 18 | 19 |

| 1/2 | 14 | 14 |

| ¾ | 14 | 14 |

| 1 | 11 ½ | 11 |

| 1 ¼ | 11 ½ | 11 |

| 1 ½ | 11 ½ | 11 |

| 2 | 11 ½ | 11 |

| 2 ½ | 8 | 11 |

| 3 | 8 | 11 |

| 3 ½ | 8 | 11 |

| 4 | 8 | 11 |

| 5 | 8 | 11 |

| 6 | 8 | 11 |

Conclusion

Pipe threads are the unsung heroes of various industries, enabling the seamless flow of fluids and the construction of reliable structures. Understanding the different thread types, applications, and best practices is crucial for achieving leak-free connections and ensuring the longevity of your projects. Whether you’re a plumber, engineer, or simply someone curious about the intricate world of pipe systems, a solid grasp of pipe threads will undoubtedly serve you well.

Hi Mr. Kumar Dey,

I’m really having a headache with pipe thread sizes right now. I bought an instantaneous water heater which was made in China. The inlet and the outlet are stated to be 1/2″ NPT…pretty standard. (I give the Chinese credit for trying to match our American standards.) The problem is that when I go to the home improvement store (Home Depot), to buy fittings, I am met with different size designations, for example: MIP/FIP, MPT/FPT. and MHT/FHT. Interestingly, many of the plumbing parts and fittings they sell are also made in China. This situation is getting crazy. There are already way too many different sizes, and determining compatibility is impossible unless you take your item in to the store to try each fitting to assure a good fit. But the stores don’t like letting you do that because all of their parts are sold in sealed packages. It’s a no-win situation.