A pipe union is a type of pipe fitting that creates a secure and semi-permanent connection between two pipes. The pipes can easily be separated without causing any piping deformation. Pipe union connections are mostly used for small bore pipe connections. Whenever an easy assembly and disassembly along with a positive sealing is required, pipe union fittings are used. Common pipe unions are usually manufactured in a size range from 1/8 inches to 4 inches.

Parts of a Pipe Union Fitting

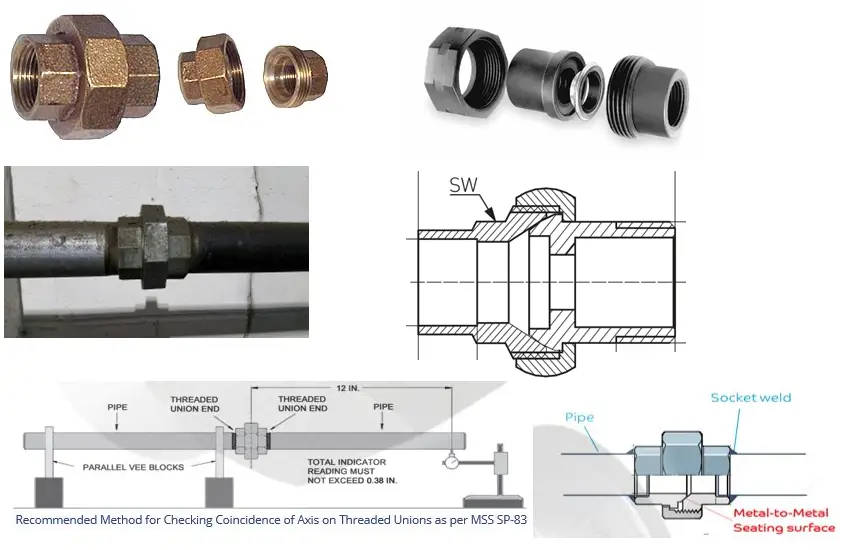

A pipe union has three parts; a male end, a female end, and a nut (Refer to Fig. below). The male and female ends of the piping union are sealed together in the nut to act as a single pipe union assembly. The female end has threads on the inside surface whereas the male end has threads on the outside surface. The nut provides the required sealing pressure to the union joint.

The threaded pipe union is threaded to be NPT per ASME B1.20.1 whereas the nut is straight thread as per ASME B1.1. The seating surfaces of the joint shall be integral metal-to-metal, ball-to-cone design.

Applications of Pipe Unions

As pipe unions have a high probability of leakage, their use is generally limited to non-hazardous and non-flammable services. The use of pipe unions is found in the following systems:

- Fire Protection Piping System

- Water and Wastewater piping systems

- Non-critical Process piping systems with low pressure and temperatures

- Plumbing Applications.

Types of Pipe Unions

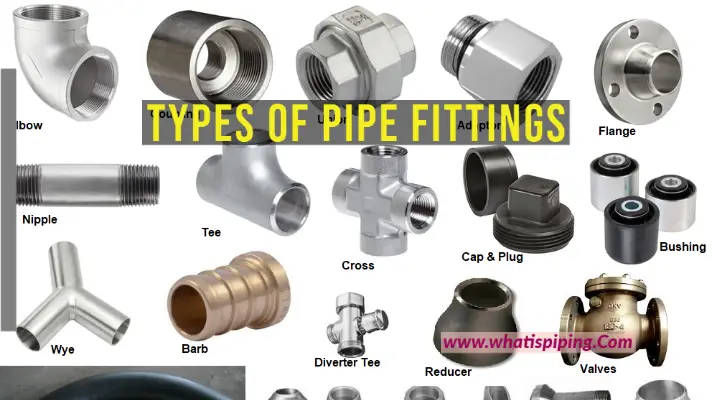

There are two types of pipe unions that are found in applications as listed below:

Ground Joint Union: It comprises an angle that is cut into the piping union to make the two sections meet to increase the joint surface area which helps in proper seating. It consists of three pieces.

Flange Union: In this type of union, a pair of flanges hold two pipes together by screwing them on the ends of the pipes. This is usually used in plumbing services to hold both pipes together. It consists of only two pieces.

Again, depending on the joint connection, there are two types of pipe unions; threaded union and socket welded union.

Materials for Pipe Unions

Industrial pipe unions are made from various materials. Some of the common pipe union materials are:

- Carbon Steel (ASTM A105, A350, A234)

- Stainless Steel (ASTM A182 , A312, A403)

- Cast Iron

- Copper (ASTM SB111)

- Brass

- Nickel (ASTM B336)

- Alloy Steel (A335/A691)

- Duplex Stainless Steel (A790)

- Aluminum

- Bronze

- Plastics like PE, PVC,

- Rubber, etc

Metallic pipe unions are preferred for piping industries whereas plastic pipe unions are generally used in plumbing services.

Pipe Union Manufacturing Standards

The most widely used pipe union standards are:

- MSS SP 83, and

- ASME B16.11

- BS 3799

Features of Pipe Union

The main characteristic features of pipe unions are:

- Two pipes of different sizes can be joined together using a pipe union.

- The joining can be easily disengaged.

- Metering and regulating devices are connected using unions.

- They are easy to install and economical.

Specification of a Pipe Union

A pipe union fitting is generally specified by the following information:

- Manufacturing standard

- Material Grade

- Dimension/Pressure Class: Class 2000/3000/6000/9000

- Type of Union: Socket union/Threaded union

- Size

- Value-added services: galvanizing/coating/polishing requirements

Difference between Pipe Coupling and Pipe Union | Pipe Union vs Pipe Coupling

Pipe unions are quite similar to pipe couplings. However, they have some differences as mentioned below:

1. Pipe Connection:

Two coupled pipes screw together directly, one inside the other. While taking the pipes apart, every pipe that connects to the coupled pipe needs to turn.

While in a pipe union, the two pipe ends don’t screw into one another—they each screw into a third piece. When one pipe needs to come apart from the other, the union piece simply screws onto one of the two pipes completely. If both ends of a pipe are attached using a union, the pipe may be removed on its own without unscrewing the other pipes in the system.

2. Joining Method:

Pipe couplings are available in three pipe joining modes; threaded, butt welded, and socket welded. On the other hand, pipe unions only have two pipe joining modes; threaded and socket welded.

3. Use:

Pipe couplings can be used in comparatively high-pressure services as compared to pipe union connections. Couplings are used in pipe racks whereas unions are used for steam trap assemblies and control valve manifolds. Couplings are used as a piping/pipeline extension while unions are more versatile as they are used with other pipe components as well.

4. Cost:

The cost of pipe unions is comparatively higher than the cost of pipe couplings.

5. Purpose:

Pipe couplings are generally used as a permanent joint, whereas pipe unions are specifically used for parts requiring maintenance and repair for easy disengagement.

Possible Causes of leakage from pipe union

The following are some of the probable causes that can create a leakage problem from pipe unions.

- Improper or low assembly torque of the collar

- Imperfections of the metal-to-metal seat

- Dirt on the metal-to-metal seat

- High friction in the collar threads

- Piping misalignment causing improper seating or uneven tightening

- High vibration during operation

- In addition to the possible cause of leakage through pipe thread or socket weld failure.

In certain applications, a pipe union as a pipe fitting is used as a protective system to avoid galvanic corrosion. Plastic pipe unions when used with two pipes made of different metals, act as a barrier for electronic movement from one pipe metal to the other. The physical separation slows down the galvanic corrosion process.

Online Video Course on Piping and Pipe Fittings

To enrich yourself with piping and pipe fitting details you can opt for the following online video courses

I have a question about what you wrote with the union. Just wondering if the male and has the nut and the female and has the external threads since the female and is tapered inward and the male and has an extruding tailpiece to insert into the female as were, it says above that the female and has internal threads and the male and has external threads, but there is no internal threads on a union except for the nut not including the outside that connects to the pipe which could be male or female

Male end and female end. Not and