A steam trap is an automatic valve that allows condensate, air, and other non-condensable gases (CO2) to be discharged from the steam system while holding or trapping the steam in the system. So, Steam Traps separate out the condensate from the mixture. For any steam system in power or processing plants, the steam trap is an essential component. It retains the steam within the process which helps in the maximum utilization of heat and thereby increases energy efficiency.

Let’s first try to understand how this mixture forms:

- Condensate: Condensate forms whenever steam releases its heat energy for any reason.

- Air: Air exists in all steam pipes prior to system start-up when the system is cold. Air can enter the system through boiler water make-up systems and vacuum breakers.

- Non-Condensable gases: Gases other than air such as carbon dioxide exist inside steam systems.

So the main function of Steam Traps is to remove the liquid condensate from the mixture to avoid two-phase flow formation. Additionally, for overall efficiency and economy, the steam trap must also provide:

- Minimal steam loss.

- Long life and dependable service without Rapid wear.

- Corrosion resistance to fight the damaging effects of acidic or oxygen-laden condensate.

- Air venting for efficient heat transfer and to prevent system binding

- CO2 venting to prevent the formation of carbonic acid.

- Operation against back pressure.

- Freedom from Dirt problems by operating in the presence of dirt.

Industrial steam traps can operate over a wide range of temperatures and pressures as per the system requirement.

Applications of Steam Traps

As already mentioned that steam traps are widely used in steam lines to avoid two-phase flow and increase efficiency. Some other key applications for steam traps are:

- Drip applications: A steam trap is used to eliminate the condensate when steam loses its heat energy and starts to condensate.

- Process applications: To remove condensate and air from heat exchangers or radiators, steam traps are used to make the heat transfer process efficient.

- Tracing applications: Steam traps are used in steam tracing applications to remove the condensate formed in these pipes.

- Steam Jacketed lines

Types of Steam Traps / Steam Trap Types

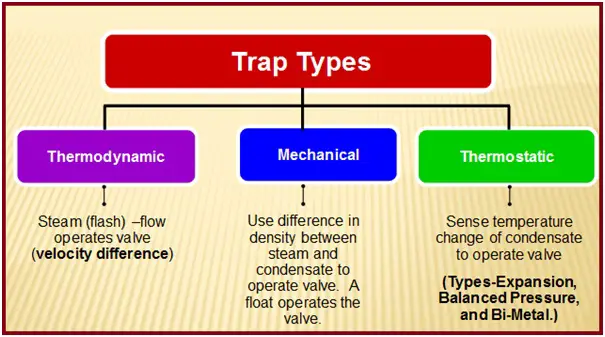

As classified by International Standard ISO 6704, there are three main types of Steam Traps as listed below:

- Thermodynamic Steam Traps

- Mechanical Steam Traps and

- Thermostatic Steam Traps

Fig. 1 clearly explains the types of steam traps.

Thermodynamic Disc Steam Traps

Thermodynamic steam traps sense the velocity difference of entering fluids. When condensate enters the trap body, it moves slowly relative to the steam and is freely discharged. When flash or live steam moves across the underside of the disc, its velocity is much higher than water, and the high speed creates a pressure drop which closes the valve head. The valve stays shut until the control chamber steam pressure above the valve head drops, thereby allowing the valve to open.

Types: Thermodynamic Disc and Thermodynamic Piston.

Since air moves much faster than condensate; thermodynamic disc traps tend to close in the presence of air and are generally not suited for venting large amounts of air.

Thermodynamic Disc & Thermostatic steam traps: To handle air, a combination of thermodynamic disc traps and thermostatic air vents can be used.

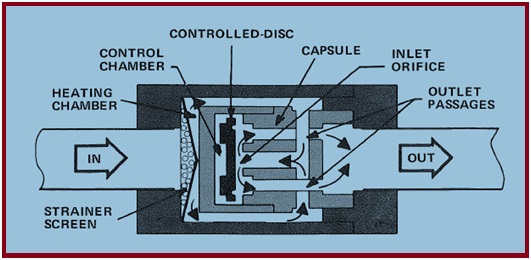

Operation of Disc Steam Trap

- Disc traps operate as a function of velocity. Under normal operating conditions, condensate and air enter the trap and pass through an inlet orifice, a control chamber, and an insulating chamber (to isolate the trap against the effects of the environment).

- Rated to operate 10 to 600 PSIG.

- Small and lightweight therefore easy to install.

- Frequently inspection required, not energy efficient because of short service life.

- Not suitable when backpressure is high.

Thermostatic Steam Traps

Thermostatic steam traps sense the temperature difference of entering fluids. The closure occurs when the fluid, typically hot condensate, has a temperature greater than or equal to a certain threshold value. The hot temperature causes a thermostatic element to move in such a manner that closes a valve. This temperature threshold value is below that of saturated steam.

- Since air has a temperature significantly lower than steam, thermostatic traps are generally very good at venting large amounts of air. Thermostatic traps are rated to operate from 0 to 300 PSIG.

- Fabricated with SS, CS, and cast iron housings.

- Not effective when dirt and scale are present

Basic types: Expansion, Balanced Pressure, and Bi-Metal.

Expansion Type steam traps:

- Expansion steam trap elements have an internal filling that expands and contracts with temperature change to actuate the valve, but the filling does not vaporize.

- Wax elements are in a congealed state when cool, and expand when heated.

- Petroleum-based elements are in a contracted liquid state when cool, and expand when heated

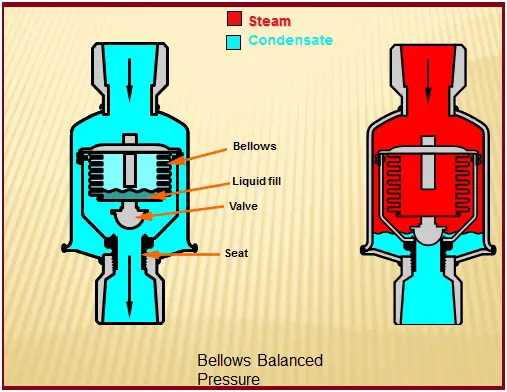

Balanced Pressure type steam traps:

Balanced Pressure steam trap elements have a filling which is a mixture of water and mineral spirits that generally vaporizes or condenses at near-to-steam temperature to actuate the valve.

Bi-Metal Steam Trap:

Bi-Metal steam trap elements are composed of two dissimilar metal strips bonded together so that temperature change causes a deflection in one direction or its opposite to actuate the valve.

Bellows balanced pressure type (Fig. 3) steam traps are suitable for High capacity whereas Wafer/Diaphragm balanced pressure is suitable for Low capacity. On the other hand, Bi-metallic steam traps can be used both for High or low capacity.

Mechanical Type Steam Trap

Mechanical steam traps are designed to open for more-dense fluids and close for less-dense fluids. There are two basic categories of mechanical steam traps that operate on the density principle:

- Float type and

- Bucket type

Within these categories, there are two types each of density traps: Lever Float, Free Float, Inverted Bucket, and Open Bucket.

Air is less dense than water. Hence, density steam traps tend to close in the presence of air and are generally not suited for venting large amounts of air. For this reason, density traps may contain a separate thermostatic air vent mechanism to handle significant amounts of air.

- Float & Thermostatic,

- Bucket & Thermostatic.

Float and Thermostatic Steam Traps

- Float & Thermostatic steam traps combine the action of two principles: thermostatic and density. Each trap has its own discharge orifice. A valve with a ball float actuator drains condensate when the liquid reaches a predetermined level in the trap. When the flow of condensate diminishes’ the float drops, partially closing the valve to accommodate the flow rate.

- At the top of the trap is a thermostatic element that opens to discharge all air and non-condensable gases as soon as they cause a small temperature drop within the trap.

- Operate in between 0 to 250 PSIG pressure,

- The condensate valve is located at the bottom and is subject to plugging when dirt and scale are present.

- If the dirt particles prevent the valve from closing, steam energy will be wasted until the condition is detected and corrected.

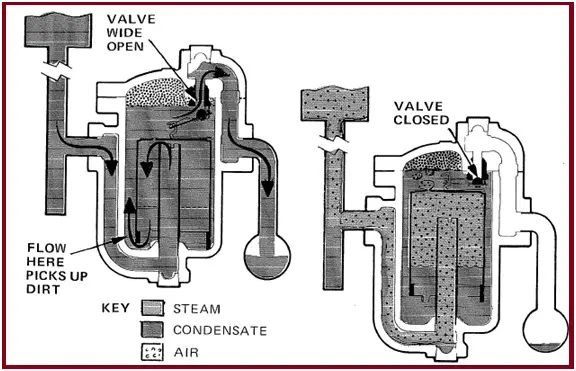

Inverted Bucket Steam Traps

Inverted bucket steam traps (Fig. 4) use an inverted bucket that is normally submerged and floats only when steam is present. The bucket sinks when the volume of condensate exceeds a predetermined liquid level. When the bucket sinks, the valve at the top opens.

Steam Trap Selection Guidelines

To get the maximum benefit from the steam traps, the selection of steam traps of the correct size and pressure is very important. The selection of steam traps shall be in accordance with the following:

- Steam traps in low-pressure steam drip service shall be inverted bucket style, mechanical traps, or bimetallic thermostatic style traps.

- Steam traps in medium-pressure steam drip service shall preferably be inverted bucket-style mechanical traps; alternatively, disc-type thermodynamic traps may be used.

- Steam traps in high-pressure steam drip service shall preferably be inverted bucket-style mechanical traps.

- Steam traps provided for steam turbine inlet drip service shall be thermodynamic piston-type traps.

A commonly accepted practice is to use float & thermostatic (F&T) steam traps for low-pressure steam systems up to 30 PSIG, and thermodynamic steam traps for steam pressures over 30 PSIG. Additionally, the following comparison table (table 1: Comparison of operating requirements for various types of steam traps) can be used as a guide for Steam Trap Selection:Steam Trap Characteristic Features Bi-Metallic Inverted Bucket Float & Thermostatic Thermostatic wafer Disc Differential Condensate controller Orifice Operating Method Irregular Irregular Continuous Irregular Irregular Continuous Continuous Conservation of Energy Excellent Excellent Good Fair Poor Excellent Poor Resistance to Wear Excellent Excellent Good Fair Poor Excellent Poor Resistance against Corrosion Excellent Excellent Good Good Excellent Excellent Good Resistance to Hydraulic Shock Excellent Excellent Poor Poor Excellent Excellent Good Non-condensable gas Venting at steam temperature No Yes No No No Yes Poor Air venting at Low pressure Not Recommended Poor Excellent Good Not Recommended Excellent Poor Start-up air load handling Excellent fair Excellent Excellent Poor Excellent Poor Back pressure Excellent Excellent Excellent Excellent Poor Excellent Poor Resistance to freezing damage Good Good Poor Good Good Good Excellent Purge Ability Good Excellent Fair Good Excellent Excellent Poor Light load performance Excellent Excellent Excellent Excellent Poor Excellent Poor Response towards slugging Delayed Irregular Immediate Delayed Delayed Immediate Poor Dirt handling ability Fair Excellent Poor Fair Poor Excellent Poor The physical size of the Steam Trap Small Large Large Small Small Large Small Flash steam handling ability Poor Fair Poor Poor Poor Excellent Poor Mechanical Failure (Close or Open) Open Open Closed Either Open or Close Open Open Not Applicable

International Codes and Standards for Steam Traps

International codes and standards that govern the steam trap design are listed below:

- ISO 6552: 1980/ (BS 6023: 1981): Glossary of technical terms for automatic steam traps.

- ISO 6553: 1980/CEN 26553: 1991 (Replaces BS 6024: 1981) Marking of automatic steam traps.

- ISO 6554 1980/CEN 26554: 1991 (Replaces BS 6026: 1981) Face-to-face dimensions for a flanged automatic steam trap.

- ISO 6704: 1982/CEN 26704: 1991 (Replaces BS 6022: 1983) Classification of automatic steam traps

- ISO 6948:1981/ CEN 26948: 1991 (Replaces BS 6025: 1982) Production and performance characteristic tests for automatic steam traps.

- ISO 7841: 1988/CEN 27841: 1991 (Replaces BS 6027: 1990) Methods for determination of steam loss of automatic steam traps.

- ISO 7842: 1988/CEN 27842: 1991 (Replaces BS 6028: 1990) Methods for determination of discharge capacity of automatic steam traps.

- ASME PTC39: Steam Traps.

- ASTM F1139: Standard Specification for Steam Traps and Drains

- FCI 85-1: Standard for Production Testing for Steam Traps.

- FCI 69-1: Pressure Rating Standard for Steam Traps.

Sizing Steam Traps

Steam traps are not chosen based on the existing pipe size. Various factors are required to accurately size steam traps.

- Condensate loads: Depending on the condensate load, the recommended size of equipment outlet piping is provided in Table 2

- Safety factor to use: Safety factor should be selected based on experience. The values of the safety factor usually vary between 1.5 to 10.

- Pressure differential: The steam trap should be able to open against the maximum pressure differential present in the system.

- Maximum Allowable Pressure: The steam traps must be designed for the design pressure.

| Maximum Condensate Load | Equipment Discharge Piping Size |

| Less than 200 kg/h | 15 mm |

| 200 – 500 kg/h | 20 mm |

| 0.5 – 1 MT/h | 25 mm |

| 1 – 2 MT/h | 32 mm |

| 2 – 3 MT/h | 40 mm |

| 3 – 5 MT/h | 50 mm |

| Over 5 MT/h | 65 – 100 mm |

Causes of Steam Trap failure

Common Causes of failure of steam traps are:

- Corrosion, due to the condition of the condensate. This can be countered by using particular materials of construction, and good feed-water conditioning.

- Water hammer, often due to a lift after the steam trap, traps.

- Dirt accumulates from a system where the water treatment compound is carried over from the boiler, or where pipe debris is allowed to interfere with trap operation.

The failure of a steam trap has severe implications for the steam system’s performance. If the steam trap fails in open condition, it will leak the steam and condensate completely causing increased steam consumption which in turn will add increased load to the boiler. However, when it fails in closed condition, neither steam nor condensation will pass through it. So the function of the steam trap will be halted which could lead to any of the following problems:

- Surge or Water hammer

- Waterlogging of the process

- The presence of water (Condensate) in the steam system is a safety hazard.

So, it is essential to regularly monitor steam trap performance and fix the failed steam traps.

Steam Traps Performance Assessment

The performance of Steam Traps is assessed using any of the three methods mentioned below:

- Visual Method-Visual inspection is performed using sight glasses.

- Sound Method-Involves Distinguishing between Sound Frequencies using auditory equipment.

- Temperature Methods-Works on temperature difference principle. However, Least Reliable method and hence normally not used.

Normally, preventive maintenance is performed for steam traps and the maintenance schedule depends on the pressure rating of the steam trap. As a thumb rule, high-pressure steam traps with a pressure rating greater than 250 psig should be tested daily. On the other hand, low-pressure steam traps with a pressure rating below 30 PSIG can be checked annually. Intermediate ones should be checked monthly. As a general rule, steam traps should be replaced after every three to four years.

Feature Requirements in Steam Traps

An Ideal steam trap should possess the following features for its best performance:

- The steam trap should allow the condensate to pass and trap the steam.

- Steam traps must be energy efficient and have negligible steam consumption. The steam trap must ensure that the steam space must be filled with clean dry steam. The type of steam trap will influence this.

- Steam traps should possess good air venting capability. If air mixes with steam it will reduce the steam temperature.

- It’s preferable that steam traps should not cause steam flashing.

- Steam traps must have high Reliability. Sometimes, various external factors can cause unreliability in steam trap usage like

- Corrosion

- Water hammer and

- Dirt or debris accumulation.

Steam trap Installation

Click here to know the steam trap installation best practices.

Steam Trap Malfunctioning

Knowing if a steam trap is working smoothly is important from an operational viewpoint. Various signs or indications are obtained in case steam traps are not working properly.

- An abnormal increase in the boiler room temperature.

- Frequent change in boiler operational pressure makes maintenance a challenge.

- Water sealing of condensate pump.

- Lack of heating in the air-conditioned space.

- Slugging in the steam and condensate line.

- Steam leakage

- Steam trap inlet and outlet line reaching the same temperature.

Steam traps therefore must be maintained periodically to ensure the smooth working of the traps.

Steam Trap Maintenance

Steam trap maintenance philosophy usually consists of 3 stages:

- Routine Maintenance: Cleaning and Checking at regular intervals to find any faults in it.

- Replacing internal parts: Old internal parts of the steam trap should be replaced with new ones (Usually every 3 years) will ensure the undisturbed working of the steam trap assembly.

- Replacing the Steam trap: If changing the internal parts does not resolve the problem, it is wise to replace the steam trap and install a new one.

Dear Sir/Madam,

I am a Piping Designer,

it’s very nice topic to know all about sta drip leg etc.

Thanks for good info

Regards

i need to how to calculate the steam trap in steam line any principles or producer?

Thanks for the detailed info on drip leg designing.

This is a very good overview on how and when to use different steam trap. Personnaly, for drip leg applications, I prefer the bi-metalic design. I found them more robust and some manufacturer offer an easy feature to adjust the temperature discharge. Remember, drip leg application have very low load of condensate. So if the drip leg is well done, there will be no worries regarding the amount of condensate that accumulate in the pipe.

Thanks for your excellent post!

Pretty great post. I simply stumbled upon your weblog and wished to say that I’ve truly enjoyed

surfing around your weblog posts. After all I’ll be subscribing in your feed and I’m hoping

you write once more soon!

I need to know the function and financial benefits of installing Vacuum breaker and Thermostatuc traps on the top of steam distribution lines after 30 meters. Pls reply over mail.

Great blog post. Knowledgeable.