In the world of engineering and construction, ensuring the structural integrity of various components is paramount. Nuts and Bolts, often overlooked but essential fasteners, play a critical role in securing joints and connections. ASTM A194 is a standard specification that sets the guidelines for the selection of high-strength nuts intended for use in conjunction with high-strength bolts in different industrial applications. In this blog post, we will jump into the fascinating world of ASTM A194, exploring its significance, classifications, and the importance of adhering to its standards.

What is ASTM A194?

ASTM A194 is a standard developed and published by the American Society for Testing and Materials (ASTM), now known as ASTM International. The specification covers a range of carbon, alloy, and stainless steel nuts primarily designed for use in high-pressure and high-temperature applications. These nuts are used in conjunction with high-strength fasteners such as ASTM A193 bolts to ensure a robust and reliable connection. The usual size range for ASTM A194 nuts is 1⁄4 through 4 in. and metric M12 through M100 nominal. SA 194 is the ASME designation of ASTM A194 Nuts.

Significance of ASTM A194

Bolting failures in industrial equipment and structures can have catastrophic consequences. The ASTM A194 standard plays a pivotal role in preventing such failures by specifying the necessary requirements for nuts used in critical applications. Compliant with this standard, manufacturers produce nuts that are capable of withstanding extreme conditions, providing a safety margin for crucial connections in industries such as oil and gas, petrochemical, power generation, and more.

ASTM A194 Grades and Classifications

ASTM A194 provides various classes and grades, each tailored to specific material types and mechanical properties. The most common grades of ASTM A194 include:

ASTM A194 Grade 2H:

This class comprises carbon steel heavy hex nuts and is intended for use with ASTM A193 Grade B7 bolts. It offers excellent tensile strength and is commonly used in high-temperature and high-pressure applications.

- Material: Carbon steel heavy hex nuts.

- Usage: Intended for use with ASTM A193 Grade B7 bolts.

- Mechanical Properties: High tensile strength and suitable for high-temperature and high-pressure applications.

- Application: Commonly used in industries such as oil and gas, petrochemicals, and power generation.

ASTM A194 Grade 4:

This class includes carbon and alloy steel heavy hex nuts. Similar to Grade 2H, these nuts are utilized with ASTM A193 Grade B7, Grade B16, or Grade B8M bolts, depending on the specific material.

- Material: Carbon and alloy steel heavy hex nuts.

- Usage: Used with ASTM A193 Grade B7, B16, or B8M bolts, depending on the specific material.

- Mechanical Properties: Offers high strength, making it suitable for various high-pressure applications.

ASTM A194 Grade 7:

This class is designed specifically for use with ASTM A193 Grade B8M bolts, which are made of stainless steel with excellent corrosion resistance.

- Material: Stainless steel nuts.

- Usage: Intended for use with ASTM A193 Grade B8M bolts.

- Mechanical Properties: Provides excellent corrosion resistance, making it ideal for applications in corrosive environments, including chemical processing industries.

ASTM A194 Grade 8/8M:

A194 Grade 8/8M nuts are manufactured from high-strength stainless steel and are used with ASTM A193 Grade B8M and Grade B8 bolts.

- Material: High-strength stainless steel nuts.

- Usage: Used with ASTM A193 Grade B8 and B8M bolts.

- Mechanical Properties: Provides excellent resistance to corrosion, making it suitable for applications in corrosive environments.

ASTM A194 Grade 3:

- Material: Alloy steel heavy hex nuts.

- Usage: Intended for use with ASTM A193 Grade B16 bolts.

- Mechanical Properties: Provides high strength and is suitable for high-temperature applications.

Chemical Composition of ASTM A194 Nuts

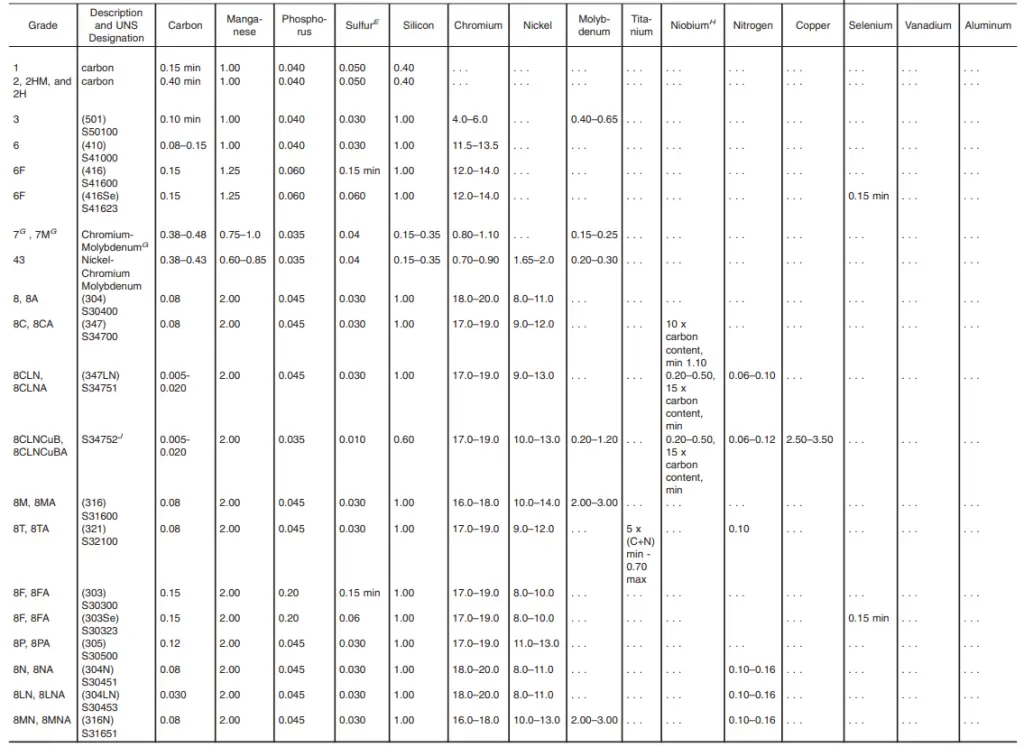

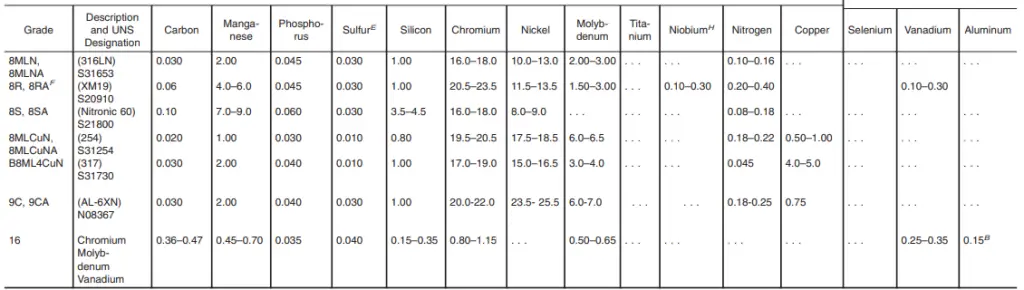

The chemical composition of ASTM A194 Nuts is given in Fig. 1 and 2 with respect to its grades:

Importance of Adhering to ASTM A194 Standards

Ensuring that nuts used in high-pressure and high-temperature applications comply with ASTM A194 standards is crucial for several reasons:

- Safety and Reliability: Compliance with the standard ensures that the bolts and nuts used in critical connections possess the necessary mechanical properties to withstand extreme conditions, minimizing the risk of failure and ensuring the safety and reliability of the structure or equipment.

- Interchangeability: Standardized nuts allow for interchangeability, making it easier to replace or upgrade fasteners without compromising the integrity of the joint.

- Quality Assurance: Manufacturers adhering to ASTM A194 standards follow strict quality control procedures, resulting in nuts that meet consistent quality benchmarks.

Differences between ASTM A194 Gr 2H and ASTM A194 Gr 8

Here’s a tabular comparison highlighting the key differences between ASTM A194 Grade 2H and ASTM A194 Grade 8 nuts:

| Property | ASTM A194 Grade 2H | ASTM A194 Grade 8 |

|---|---|---|

| Material | Carbon steel | High-strength stainless steel |

| Usage | ASTM A193 Grade B7 bolts | ASTM A193 Grade B8 and B8M bolts |

| Mechanical Properties | High tensile strength | Excellent corrosion resistance |

| Application | High-temperature and high-pressure applications | Suitable for corrosive environments |

| Compatibility | Used with ASTM A193 Grade B7 bolts | Used with ASTM A193 Grade B8 and B8M bolts |

Conclusion

In conclusion, ASTM A194 plays a vital role in ensuring the structural integrity of industrial equipment and structures. By setting specific standards for high-strength nuts used in conjunction with high-strength bolts, this specification provides a framework for manufacturers to produce reliable, safe, and efficient fastening solutions. Adhering to ASTM A194 standards is not just a matter of compliance; it is a commitment to safety, quality, and the overall well-being of the industries it serves. So, the next time you see a robust structure standing tall, remember that it is likely thanks, in part, to the often-overlooked, yet essential, ASTM A194 nuts and bolts securing its joints.