The outermost surface of any metal is the most important area as it suffers from direct impact and abrasion while in operation. So, it is always desirable to make the metal surface abrasion-resistant. This is achieved by altering the surface hardness of the metal using a method called case hardening. This is also popular as the surface hardening process. In the following paragraphs, we will learn more details about the case hardening process, its purpose, types of case hardening methods, and applications.

What is Case Hardening? / Case hardening definition

Case hardening is a material processing technique by which the hardness of the outer surface of a metal is increased while keeping a soft ductile core. This surface hardening method creates a thin layer of a wear-resistant, hard case which in turn increases the impact strength of the component as a whole. The case hardening process involves altering the crystal structure of the metal or chemical composition by adding new elements to the metal surface at elevated temperatures. As with an increase in hardness the machinability usually reduces, the case hardening is performed at the final step after all other fabrication processes.

Purpose of Case Hardening

The main purposes for case hardening processes are:

- Due to the development of compressive stresses in the outer surface layer, case hardening increases the fatigue strength of the metal and alloy.

- The combination of hard surface and ductile core imparts optimum wear resistance and toughness properties.

- Case hardening increases durability and usage economy of parts.

- Case hardening improves the weldability in certain materials.

Reason for Case Hardening

By case hardening the outer surface only, in place of the entire metal object, the efficiency of the process is improved. The requirement of energy and time both reduces as heating the outer surface requires less heat as compared to the entire metal section. So, these cause huge savings in costs for large manufacturing units. Also, the performance of the material increases.

Metals Suitable for Case Hardening

Ferrous metals are the most common metals which are subjected to case hardening treatment. Special cases of nitriding in some aluminum and titanium alloy can be applied but not frequently. The widely used ferrous materials that are subjected to the case hardening process are:

- Low carbon steels

- Stainless steels

- Cast Irons

- High Carbon Steels

- Tool Steels

- High Strength Low Alloy Steels

Case Hardening of Steel

There are various means by which the case hardening of steel can be achieved. Depending on the desired properties in the finished product and the metals used in manufacturing, the specific type of case hardening process for steel is selected. For case hardening of steel i.e to make the hard case but softcore, two general processes are used:

- In the first case hardening method, the chemical composition of the outer surface is altered using diffusion processes like carburizing, nitriding, cyaniding, carbonitriding, boriding, titanium-carbon diffusion, etc. and

- Only the surface layer is hardened by heating and quenching processes. Examples of such case hardening methods are flame hardening, induction hardening, laser hardening, ion implantation, electron beam hardening, etc.

The first method mentioned above is known as the diffusion process. In this case hardening method of steel, the chemical composition of the outer surface of the steel is changed with hardening species such as carbon, nitrogen, cyanide, or boron. Diffusion methods of case hardening are ideally suitable when a large number of parts are to be surface-hardened. Depending on the types of steel the selection of case hardening methods varies as listed below:

- Low Carbon Steels: Carburizing, Cyaniding, Carbonitriding, Ferritic nitrocarburizing.

- Alloy Steels: Nitriding, Ion Nitriding

- Tool Steels: Titanium carbide, Boriding, Salt nitriding, Ion nitriding, Gas nitriding.

- Stainless Steels: Gas nitriding, Ferritic nitrocarburizing, Titanium carbide, Ion nitriding

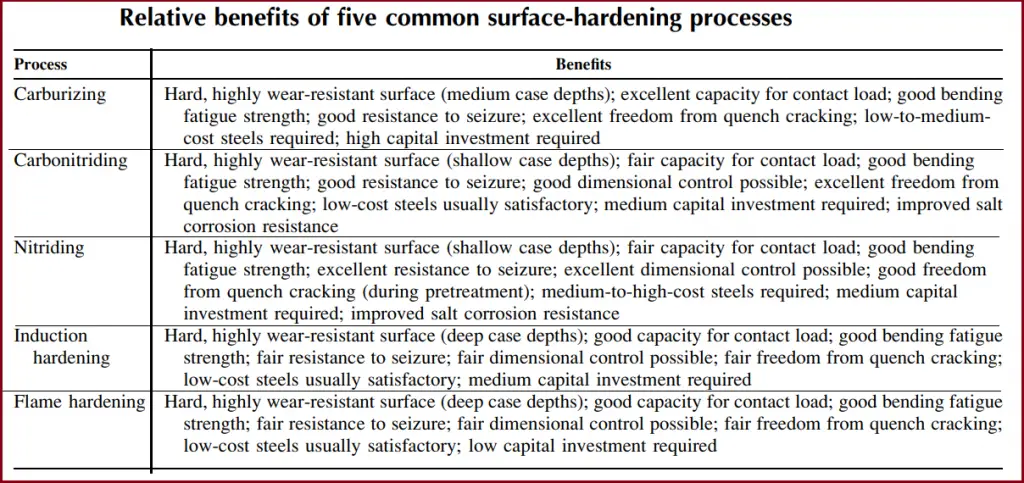

Whereas the second method, known as the selective surface hardening method allows localized hardening by heating and quenching. Flame and induction hardening for case hardening of steel materials are generally limited to certain families of steels, such as medium-carbon steels, medium-carbon alloy steels, some cast irons, and the lower-alloy tool steels. The relative benefits of the five most common and widely used case hardening methods are provided in the image below:

Applications of Case Hardening Process

Components subjected to high pressures, constant wear or abrasion, and sharp impacts are usually case-hardened. Examples of such parts include firing pins, rifle bolt faces, or engine camshafts. In all of these components, the bulk of the part is kept in the original ductile state and the surfaces are case hardened to act properly.

Another widely used application of case-hardening is self-drilling screws. To have the properties of drilling, cutting, and tapping into other materials, the drill point and the forming threads are case-hardened keeping the core as soft to retain the ductile behavior. Other examples of case hardening include

- Gears

- forging presses

- Fasteners

- metal rolling equipment

- Camshafts

- machine tools

- Rods

- drivelines of mining equipment and heavy-duty transmissions

- Pins

- Theft prevention lock shackles and chains

- earthmoving equipment and heavy-duty construction cranes

What is the difference between surface hardening and case hardening?

The major differences between case hardening and surface hardening and provided in a tabular format below:

| Case Hardening | Surface Hardening |

| In the case hardening process, the metal surface is hardened by infusing other elements. | In the surface hardening process, no infusion of other elements is done to increase hardness. |

| The thickness of the hardened outer layer known as the case is comparatively smaller than surface hardening methods. | The thickness of the hardened surface is more. |

| Case hardening process involves red heating of the steel and then infusing carbon or nitrogen into the surface and then quick quenching. | Surface hardening involves heating the steel to austenitizing temperature and then quenching the surface immediately. |

Advantages of Case Hardening Process

Case hardening of steel provides various advantages as mentioned below:

- Increases durability and usage economy

- Increases the machinability of steel making them suitable for heavy-duty applications.

- Enhances the performance of case hardened steel products.

- Reduces noise and increases energy saving in some situations

- Case hardening of steel minimizes the deformation of parts.

- Improves fracture resistance

- Improves corrosion and abrasion resistance

- Increases weldability of steel

- Reduces distortion

- Case hardening of steel increases fatigue resistance.

Reference and Further Studies

To know more about case hardening and the various processes click here.