When it comes to fasteners, there’s a wide variety to choose from, each with its own unique purpose and design. From the common nuts and bolts to more specialized fasteners like rivets and screws, they all play a crucial role in holding things together. In this blog post, we’re going to learn about the castle nut. Castle nuts are commonly used in applications where safety and security are paramount, such as in automotive suspension systems, aircraft construction, and various industrial machinery.

What Is a Castle Nut?

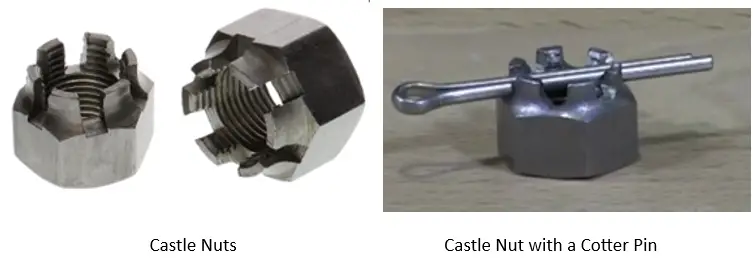

A castle nut is a type of fastener with a distinct design. It’s called a castle nut because of its appearance: it resembles the turrets of a medieval castle. The most defining feature of a castle nut is the slots or notches that are cut into one end of the nut. These slots allow for the insertion of a cotter pin or a similar locking mechanism. They are also popular as spindle nut or castellated nuts.

Castle nuts are hexagonal in shape and have six slots with a 60-degree space in between. Using the cotter pins and protruding triangular sections, castellated nuts create a locking mechanism that is able to withstand movement and vibrations. They are designed with unified inch fine or coarse (UNF or UNC) threads of varying diameters.

Working of a Castle Nut

Castle Nut’s distinctive features and working principle involve the use of slots or notches, which enable the application of a secondary locking mechanism, typically a cotter pin or a split pin. Here’s how a castle nut works:

- Nut Design: A castle nut looks like a regular hexagonal nut, with the main difference being the slots or notches cut into one end of the nut. These slots extend radially outward from the center hole of the nut.

- Thread Engagement: Like any other nut, a castle nut is threaded onto a bolt or threaded rod. The threads on the inside of the nut engage with the threads on the external surface of the bolt or rod.

- Tightening: To secure the castle nut and the attached component, it is tightened onto the bolt by rotating it clockwise. As you tighten the nut, it applies axial force to the components it is securing, bringing them closer together.

- Locking Mechanism: The crucial aspect of a castle nut’s design is the slots or notches on one end. These slots are evenly spaced around the circumference of the nut. After the nut is tightened to the desired level of torque, the slots align with a hole in the threaded bolt or rod.

- Cotter Pin Installation: Once the slots align with the hole in the bolt or rod, a cotter pin or split pin is inserted through the hole. The cotter pin is typically bent at its ends, securing it in place and preventing it from coming out.

- Secured Connection: With the cotter pin in place, the castle nut is effectively locked in position. The cotter pin prevents the nut from loosening due to vibrations, dynamic loads, or other forces that might act on the secured components.

Uses of Castle Nuts

Castle nuts are found in a variety of applications. Some of the common uses of castellated nuts are:

Safety Critical Applications:

One of the primary uses of castle nuts is in safety-critical applications. They are commonly used in conjunction with a drilled bolt and a cotter pin to secure parts that must not come loose. This makes them ideal for applications in industries such as aviation, automotive, and construction where safety is paramount.

Suspension Systems:

Castle nuts are frequently used in the suspension systems of vehicles, including cars, trucks, and motorcycles. They secure components like ball joints and tie rods, ensuring that they remain tightly fastened, even in high-stress situations.

Axle Assemblies:

In the world of heavy machinery and trailers, castle nuts find their place in securing axle assemblies. This ensures that wheels stay firmly attached and aligned, preventing accidents and damage.

Agricultural Equipment:

Farming equipment relies on castle nuts to keep various parts securely fastened, including wheels, blades, and plow components.

Home and Garden Tools:

While castle nuts are often associated with heavy-duty applications, they’re also used in smaller equipment and tools like lawnmowers and garden tractors.

Why Choose Castle Nuts?

- Security: The slots in castle nuts allow for the insertion of a cotter pin, which acts as a secondary locking mechanism. This double-locking system adds an extra layer of security, ensuring that the nut remains in place, even in extreme conditions.

- Easy Inspection: The slots in castle nuts make it easy to visually inspect whether the cotter pin is properly in place. This simplifies maintenance and safety checks.

- Cost-Effective: Castle nuts are a cost-effective solution for securing critical components. They are widely available and relatively inexpensive.

- Versatility: Castle nuts come in various sizes and materials, making them suitable for a wide range of applications.

Materials for Castle Nuts

Castle nuts, like many other fasteners, can be made from various materials, each chosen based on the specific application’s requirements, including factors such as strength, corrosion resistance, and environmental conditions. Here are some common materials used for manufacturing castle nuts:

- Steel: Steel is the most commonly used material for castle nuts due to its excellent combination of strength and affordability. Low-carbon steel (such as Grade 2 or Grade 5) is suitable for general applications, while high-carbon steel (such as Grade 8) provides even greater strength. Stainless steel is also used for applications requiring corrosion resistance.

- Brass: Brass castle nuts are used in applications where corrosion resistance is critical, and a more aesthetic appearance is desired. They are often used in marine or decorative applications.

- Aluminum: Aluminum castle nuts are lightweight and corrosion-resistant. They are commonly used in aerospace and aviation applications, as well as in lightweight structures where weight savings are essential.

- Bronze: Bronze castle nuts are known for their corrosion resistance and strength. They are often used in marine and underwater applications, as well as in situations where high temperatures are a concern.

- Plastic: Some non-critical applications use plastic castle nuts, often made from materials like nylon or polyethylene. These materials are lightweight and corrosion-resistant but may not provide the same level of strength as metal castle nuts.

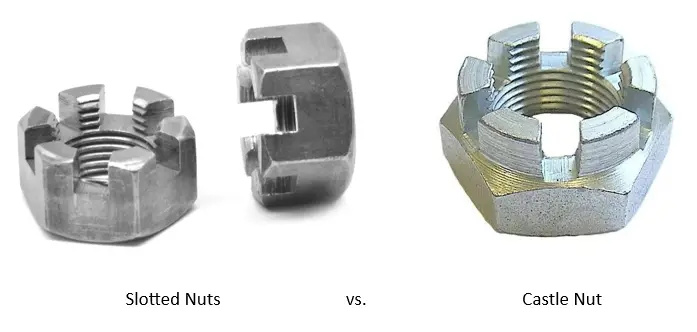

Castle Nuts vs. Slotted Nuts

Sometimes, castle nuts are referred to as slotted nuts. But technically, slotted nuts are slightly different from castellated nuts. The main difference between a slotted nut and a castle nut is that castle nuts are formed with a round section at the top where the slots are located but slotted nuts do not have this rounded modification. In slotted nuts, the flat side extends fully from top to bottom. Refer to Fig. 2 below.

Castle Nut Wrench

A castle nut wrench or castellated nut wrench is a specialized tool designed for tightening or loosening castle nuts. Castle nuts have slots or notches cut into one end, and these notches require a tool that can engage with them to apply torque effectively. Refer to Fig. 3

Here are the key features and uses of a castle nut wrench:

- Design: Castle nut wrenches are typically box-end wrenches or socket wrenches with a unique design on one end. This design allows them to fit securely onto the castle nut’s notched or slotted end.

- Notch Engagement: The end of the wrench that fits the castle nut has prongs or extensions that match the pattern of the slots or notches in the nut. This design ensures a snug and secure fit, preventing slippage during the tightening or loosening process.

- Secure Grip: Castle nut wrenches provide a secure grip on the nut’s slotted end, allowing for precise control and application of torque. This is important when working on critical applications where proper torque is essential.

- Versatility: Castle nut wrenches come in various sizes to accommodate different castle nut dimensions. It’s important to use the correct size wrench to ensure a proper fit and avoid damaging the nut.

While castle nuts may not be the most famous fasteners, they play a crucial role in ensuring the safety and stability of a wide range of applications. Their distinctive design, which allows for the use of cotter pins, adds an extra layer of security that is invaluable in safety-critical situations. Whether you’re working on a car, a tractor, or a suspension bridge, the castle nut is a reliable and cost-effective choice for keeping things securely fastened. So, next time you come across one, remember the unsung hero of fasteners, the castle nut, and its vital role in keeping the world running smoothly.

Frequently Asked Questions-FAQ

What is a castle nut, and why is it called that?

A castle nut is a type of fastener with slots or notches cut into one end. It’s called a castle nut because its appearance resembles the turrets of a medieval castle.”

What is the purpose of the slots or notches on a castle nut?

The slots on a castle nut serve as a means to secure the nut in place by allowing the insertion of a cotter pin or split pin. This double-locking mechanism prevents the nut from loosening due to vibration or other external forces.

Where are castle nuts commonly used?

Castle nuts are used in a wide range of applications, including automotive suspension systems, aircraft assembly, industrial machinery, construction equipment, and agricultural machinery. They are particularly popular in situations where safety-critical connections need to be secured.

How do I choose the right size of castle nut?

To choose the correct size of a castle nut, measure the diameter of the threaded rod or bolt you intend to use the castle nut on and select a castle nut with matching dimensions.

Can I reuse a cotter pin with a castle nut?

Cotter pins are designed for one-time use. It’s recommended to replace the cotter pin with a new one if the castle nut is removed and then reinstalled.

Are there different grades or materials of castle nuts?

Yes, castle nuts are made from various materials, including steel, stainless steel, brass, aluminum, and plastic. Different grades of steel are available to provide varying levels of strength. The choice of material depends on the specific application’s requirements.

How do I install a castle nut and cotter pin?

To install a castle nut and cotter pin, follow these steps:

- Thread the castle nut onto the bolt or threaded rod and tighten it to the desired torque.

- Align the slots in the castle nut with the hole in the bolt or rod.

- Insert the cotter pin through the hole.

- Bend the ends of the cotter pin to secure it in place.

Are castle nuts reusable?

Castle nuts can typically be reused if they are in good condition and the cotter pin is replaced. However, always inspect the castle nut for signs of wear or damage before reuse.

Can I use a regular wrench on a castle nut?

While it is possible to use a regular wrench on a castle nut, it’s not recommended. Castle nut wrenches are designed specifically to engage with the notches on the nut, providing a secure grip and reducing the risk of damaging the nut or the cotter pin.