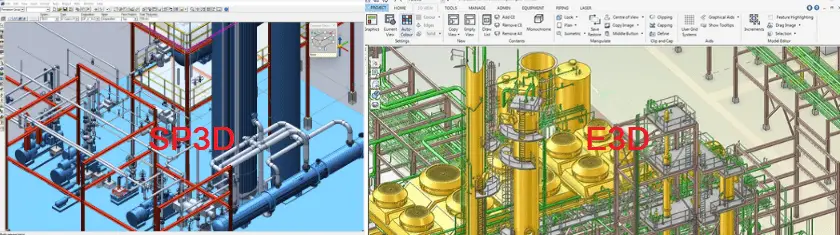

In the piping engineering design, two software solutions stand out prominently: SP3D (SmartPlant 3D) and E3D (AVEVA Everything3D). Both are robust tools utilized by professionals across industries for plant design, construction, and operations management. While they share similar objectives, there are distinct differences between SP3D and E3D that merit exploration. In this article, we’ll find out the unique features, functionalities, and advantages of each, providing a comprehensive comparison to help professionals make informed decisions.

What is SP3D or SmartPlant 3D?

SP3D, developed by Intergraph (now part of Hexagon PPM), is a comprehensive 3D modeling software tailored specifically for the engineering, procurement, and construction (EPC) industry. It offers a holistic approach to plant design, enabling engineers to create detailed models of piping, equipment, structures, and instrumentation within a unified environment. SP3D emphasizes collaboration, efficiency, and accuracy throughout the design process.

What is E3D (AVEVA Everything3D)

E3D, developed by AVEVA Solutions Limited, is another prominent player in the field of plant design software. It boasts advanced capabilities for integrated engineering, design, and construction, aiming to streamline project execution and enhance productivity. E3D leverages cutting-edge technology to deliver a flexible and intuitive platform for multidisciplinary engineering tasks, from conceptual design to as-built documentation.

Differences between SP3D and E3D

Now, let’s delve deeper into the specific features and differences between SP3D and E3D:

User Interface and Workflow:

SP3D: Known for its user-friendly interface and intuitive navigation tools, SP3D offers a structured workflow that guides users through the various stages of plant design. The interface is customizable, allowing users to tailor their workspace to suit their preferences and optimize productivity.

E3D: E3D also prioritizes user experience with a modern interface and streamlined workflow. It provides comprehensive tools for visualization and manipulation of 3D models, facilitating collaboration among multidisciplinary teams. E3D’s interface is highly configurable, enabling users to adapt the workspace according to project requirements.

Modeling Capabilities:

SP3D: SP3D excels in detailed modeling of piping systems, equipment, and structures, offering a wide range of parametric components and libraries. Its intelligent modeling features include automatic clash detection, which helps identify and resolve spatial conflicts during the design phase.

E3D: E3D boasts powerful modeling capabilities that extend beyond traditional plant design elements. It supports the creation of complex geometries, including non-standard shapes and customized components. E3D’s flexible modeling tools enable engineers to address diverse project requirements with precision and efficiency.

Integration and Interoperability:

SP3D: As part of the Intergraph suite of engineering software, SP3D integrates seamlessly with other applications such as PDS (Plant Design System) and SmartPlant Enterprise for comprehensive project management and data exchange.

E3D: AVEVA emphasizes interoperability with third-party software and industry-standard formats, allowing seamless integration with various engineering disciplines and systems. E3D’s open architecture facilitates data exchange and collaboration across different platforms, enhancing project efficiency and flexibility.

Collaboration and Documentation:

SP3D: SP3D offers robust collaboration tools, including cloud-based project management and real-time collaboration features. It also provides comprehensive documentation capabilities for generating detailed drawings, reports, and material lists.

E3D: E3D enhances collaboration through advanced visualization and review tools, enabling stakeholders to visualize the project in different stages and provide feedback. Its documentation features support the creation of accurate and up-to-date deliverables, ensuring compliance with industry standards and regulations.

E3D vs SP3D

The major differences between E3D and SP3D that are explained above are tabulated below for quick understanding and access:

| Feature/Aspect | E3D | SP3D |

|---|---|---|

| Developer | The E3D software is developed by AVEVA Solutions Limited | The SP3D software is developed by Intergraph (Hexagon PPM) |

| User Interface | E3D has a modern interface with an intuitive workflow | SP3D interface is user-friendly and easily customizable. |

| Modeling Capabilities | Supports complex geometries and is flexible. | Emphasis on piping, equipment, and structures. |

| Integration | Interoperability with third-party systems. | Seamless integration within the Intergraph ecosystem. |

| Collaboration Tools | Advanced visualization, and review features. | Cloud-based project management, real-time collaboration. |

| Documentation | Supports the creation of accurate deliverables | Comprehensive documentation capabilities. |

| Industry Focus | Plant design, construction, operations | Engineering, procurement, construction (EPC) |

| Customizability | Highly configurable interface | Customizable workspace, templates |

| Cost and Licensing | Cost varies based on features, licensing | Cost varies based on features, licensing |

| Scalability | Scalable to accommodate project growth | Scalable, suitable for large-scale projects |

| Training and Support | Available resources, support | Training, support from Intergraph/Hexagon |

| Industry Standards Compliance | Adheres to industry standards, regulations | Compliance with industry standards, regulations |

SP3D or E3D: Which Software is Better?

Determining which software is “better” between SP3D and E3D depends on various factors, including the specific needs of the project, the preferences of the engineering team, and the industry standards and requirements. Both SP3D and E3D are robust solutions with their own features and advantages, and the choice between them often comes down to individual circumstances. Here are some considerations to help evaluate which software may be more suitable:

Project Requirements:

- Consider the scope and complexity of the project. Does it involve primarily plant design, or are there additional requirements such as integrated engineering, construction, or operations management?

- Evaluate the specific functionalities and capabilities required for the project, such as modeling precision, clash detection, documentation, and collaboration tools.

User Experience and Familiarity:

- Assess the familiarity and proficiency of the engineering team with each software. Consider factors such as training requirements, ease of adoption, and the availability of support resources.

- Determine which interface and workflow align better with the team’s preferences and working style.

Interoperability and Integration:

- Evaluate the compatibility of each software with existing systems and workflows within the organization. Consider factors such as data exchange formats, interoperability with third-party software, and integration capabilities.

- Determine whether seamless collaboration and information exchange with other disciplines and project stakeholders are critical requirements.

Industry Standards and Best Practices:

- Consider industry-specific standards, regulations, and best practices relevant to the project. Evaluate how well each software supports compliance with these standards and facilitates adherence to industry guidelines.

- Assess the track record of each software in similar projects or industries to gauge its suitability and reliability.

Scalability and Flexibility:

- Consider the scalability of each software to accommodate potential future growth or changes in project requirements.

- Evaluate the flexibility of the software in adapting to evolving project needs, including the ability to customize workflows, templates, and configurations.

Cost and Licensing:

- Evaluate the total cost of ownership for each software, including licensing fees, maintenance, support, and training expenses.

- Consider the value proposition of each software in terms of its features, capabilities, and return on investment over the project lifecycle.

In summary, both SP3D and E3D are powerful software solutions for plant design and engineering, each offering unique features and advantages. While SP3D emphasizes user-friendliness and integration within the Intergraph ecosystem, E3D stands out for its advanced modeling capabilities and interoperability with third-party systems. Ultimately, the choice between SP3D and E3D depends on project requirements, industry standards, and the specific needs of engineering teams.

Nicely explained in simple terms