Ducting pipes are an essential component of any ventilation system, widely used in residential, commercial, and industrial settings. These pipes facilitate the efficient transfer of air, gases, and particles from one location to another. Whether it’s for HVAC systems, exhaust systems, or any other air circulation application, ducting pipes play a vital role in ensuring proper airflow and maintaining a healthy environment. In this comprehensive guide, we will explore the various aspects of ducting pipes, including their types, materials, installation, and maintenance.

Types of Ducting Pipes

There are several types of ducting pipes available on the market, each designed for specific purposes. Based on various parameters, ducting pipes are of different types.

A. Industrial Ducting Pipes According to Color

To help operators and construction workers with proper identification, Ducting pipes are available in different colors. Ducting pipe colors may vary from region to region. The most common color code is:

- Blue: water pipes

- Purple: cables for highway communication

- Orange: cables for traffic signals and street lighting

- Yellow: service and gas pipe

- Black: low-voltage electricity cable in a domestic context

B. Industrial Ducting Pipe Types Based on Material of Construction

According to the construction material for the ducting pipe, the following types of ducting pipes are commercially available:

- PVC Ducts: PVC ducts are made of polyvinyl chloride and are resistant to chemicals, corrosion, and moisture. They are often used in industrial settings where there is a need to transport corrosive gases or liquids. They are also commonly used for domestic appliances.

- Round Metal Duct Pipe: Duct pipes made from galvanized steel are widely used in air duct systems

- Polyethylene (PE) Duct Pipes: PE duct pipes are a popular choice for solid wall pipes.

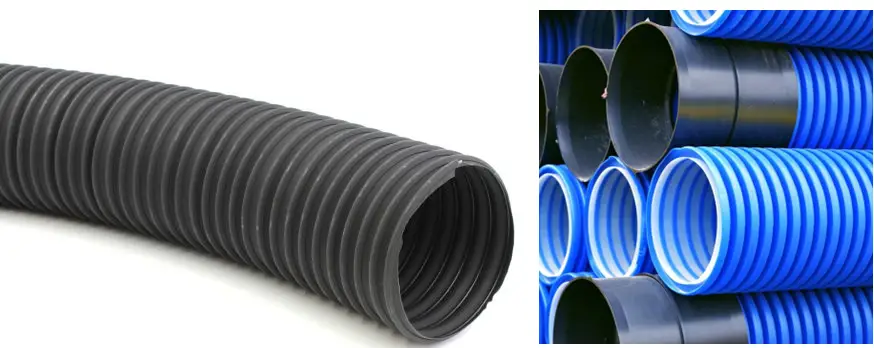

- Twinwall HDPE Ducting Pipes: This type of duct pipe is preferred for situations requiring additional protection such as underground installations. Fig. 1 below shows some examples of typical ducting pipes.

C. Types of Duct Pipes based on Rigidity

Considering the flexibility or rigidity of the duct pipes, the following types of ducting pipes are widely used.

- Flexible Ducts: These ducts are made of flexible materials such as aluminum foil or plastic, allowing for easy bending and maneuverability. They are ideal for connecting vents to air outlets, especially in tight or irregular spaces.

- Rigid Ducts: Rigid ducts, typically made of galvanized steel or aluminum, offer durability and are suitable for long straight runs. They provide better airflow and are often used in commercial and industrial applications.

- Spiral Ducts: Spiral ducts are constructed by spirally winding a continuous strip of metal, usually galvanized steel or aluminum. They are known for their strength, durability, and ease of installation. Spiral ducts are commonly found in HVAC systems.

Materials Used in Ducting Pipes

Ducting pipes can be made from various materials, each offering specific advantages depending on the application. The common materials include:

- Galvanized Steel: Galvanized steel ducting pipes are highly durable, fire-resistant, and suitable for high-temperature applications. They are often used in commercial and industrial setups.

- Aluminum: Aluminum ducting pipes are lightweight, easy to handle, and resistant to corrosion. They are commonly used in residential and commercial ventilation systems.

- Fiberglass Reinforced Plastic (FRP): FRP ducting pipes are known for their exceptional resistance to chemicals and are widely used in corrosive environments such as chemical plants and laboratories.

- Fabric: Fabric ducting pipes are typically made of polyester or other synthetic materials. They are lightweight, cost-effective, and offer uniform air distribution. Fabric ducts are commonly used in large commercial spaces.

Installation and Maintenance

Proper installation and regular maintenance are crucial for the optimal performance and longevity of ducting pipes. Here are some key considerations:

- Design and Sizing: It’s essential to design the ducting system based on the specific requirements of the space, considering factors like airflow volume, pressure, and noise control. Proper sizing ensures efficient airflow distribution.

- Installation Methods: Ducting pipes can be installed using various methods, including hanging, support brackets, or suspension systems. Follow manufacturer guidelines and consult professionals for complex installations.

- Sealing and Insulation: Proper sealing of joints and connections prevents air leakage, which can compromise system efficiency. Additionally, insulating ducts help prevent condensation and thermal losses.

- Regular Cleaning and Maintenance: Regular cleaning and maintenance of ducting pipes ensure a clean and healthy indoor environment. Remove any debris, dust, or mold buildup and inspect for damages or blockages periodically.

Energy Efficiency and Noise Control

Efficiency and noise control are important considerations when using ducting pipes. By choosing insulated ducts, you can minimize heat loss or gain and reduce energy consumption. Additionally, incorporating noise attenuators or soundproofing materials can help minimize noise transmission through the ducting system.

Compliance with Building Codes and Regulations

When installing ducting pipes, it is essential to comply with local building codes and regulations. These codes ensure safety, proper ventilation, and adherence to environmental standards. Consult with professionals or local authorities to ensure compliance.

What is Insulated Ducting Pipe?

Insulated ducting pipe, also known as duct insulation, refers to a type of ducting pipe that is designed with an additional layer of insulation material around it. This insulation layer provides several benefits, including thermal insulation, condensation prevention, and noise reduction. Insulated ducting pipes are commonly used in HVAC (Heating, Ventilation, and Air Conditioning) systems to improve energy efficiency and maintain a comfortable indoor environment. The insulation can be made of a variety of materials, including fiberglass, foam, or urethane.

Here are some key features and benefits of insulated ducting pipes:

- Thermal Insulation: The insulation layer surrounding the ducting pipe helps to prevent heat transfer between the conditioned air inside the duct and the surrounding environment. This insulation reduces thermal losses or gains, ensuring that the desired temperature is maintained within the ducting system. By minimizing heat transfer, insulated ducting pipes help to improve energy efficiency and reduce heating or cooling costs.

- Condensation Prevention: Insulated ducting pipes are effective in preventing condensation buildup on the outer surface of the ducts. When there is a temperature difference between the conditioned air inside the duct and the surrounding air, condensation can occur on the duct surface. Insulation acts as a barrier, preventing the formation of condensation and protecting the ducts from moisture-related issues such as corrosion, mold, and structural damage.

- Energy Efficiency: By reducing heat transfer and minimizing thermal losses, insulated ducting pipes contribute to overall energy efficiency in HVAC systems. Insulated ducts help to maintain the desired temperature of the conditioned air as it travels through the system, reducing the workload on heating or cooling equipment. This results in energy savings and improved system performance.

- Noise Reduction: Insulation materials used in insulated ducting pipes can help dampen and reduce noise transmission within the ductwork. The insulation layer acts as a sound barrier, absorbing or attenuating noise generated by the airflow, equipment, or vibrations. This contributes to a quieter and more comfortable indoor environment.

- Improved Air Quality: Insulated ducting pipes also play a role in maintaining good indoor air quality. The insulation layer helps to prevent the entry of dust, dirt, or contaminants from the surrounding environment into the ducts. This helps to ensure that the air circulating through the system remains clean and free from pollutants.

- Increased lifespan: Insulated ducting pipe can help to increase the lifespan of the ductwork by protecting it from the elements.

What is PVC Duct Pipe?

PVC duct pipe refers to a type of ducting pipe made from polyvinyl chloride (PVC), a durable and versatile thermoplastic material. PVC duct pipes are widely used in various industrial applications where there is a need to transport gases, fumes, exhausts, electrical conduit, or liquids, especially when dealing with corrosive substances. They offer several advantages due to the unique properties of PVC.

Here are some key features and benefits of PVC duct pipes:

- Chemical Resistance: PVC duct pipes are highly resistant to a wide range of chemicals, including acids, alkalis, salts, and many corrosive substances. This chemical resistance makes PVC ducting pipes suitable for industries such as chemical processing, wastewater treatment, laboratories, and mining, where the transportation of corrosive materials is involved.

- Durability: PVC duct pipes are known for their durability and long lifespan. PVC is a tough material that can withstand harsh environmental conditions, including high temperatures, humidity, and exposure to UV rays. PVC ducting pipes are less prone to corrosion, rusting, and degradation compared to metal ducting pipes, making them a cost-effective and low-maintenance option.

- Lightweight and Easy Installation: PVC duct pipes are lightweight, making them easy to handle, transport, and install. They are available in various lengths and diameters, allowing for flexible and customizable installations. The lightweight nature of PVC duct pipes simplifies the installation process, reduces labor costs, and makes them suitable for both new construction and retrofit projects.

- Smooth Interior Surface: PVC duct pipes have a smooth interior surface, which facilitates better airflow and minimizes pressure drop. The smooth surface also prevents the accumulation of debris or contaminants, reducing the risk of blockages and ensuring consistent and efficient airflow through the ducting system.

- Cost-Effective: PVC duct pipes are generally more affordable compared to other types of ducting materials such as metal or fiberglass. They offer a cost-effective solution for various industrial applications, especially when chemical resistance is required. Additionally, their low maintenance requirements contribute to overall cost savings over the life of the ducting system.

- Electrical Insulation: PVC is a non-conductive material, which makes PVC duct pipes an excellent choice in situations where electrical insulation is needed. This feature is beneficial in industries where the ducting system needs to avoid electrical interference or when transporting materials that may generate static electricity.

- Water-resistant: PVC is water-resistant, making it a good choice for drainage applications.

PVC duct pipe is available in a variety of sizes and colors. The size of the pipe will depend on the application. The color of the pipe is typically gray, but it is also available in other colors, such as white and black.

It’s important to note that PVC duct pipes should be selected and installed in accordance with local building codes and regulations, particularly when used in commercial or industrial settings. Consulting with professionals experienced in PVC ducting installations is recommended to ensure compliance and proper system performance.

In summary, PVC duct pipes offer chemical resistance, durability, lightweight construction, smooth interior surfaces, cost-effectiveness, and electrical insulation. These characteristics make PVC duct pipes a popular choice for various industrial applications, where the transportation of corrosive substances is required.

What is Air Ducting Pipe?

Air ducting pipe, duct tube, duct, or duct pipe is a conduit or passage used in heating, ventilation, and air conditioning (HVAC) to deliver and remove air from one location to another.It is designed to provide a pathway for airflow, allowing the distribution of conditioned air, ventilation, or the removal of stale or contaminated air from a space. The needed airflows include, for example, supply air, return air, and exhaust air. Ducts commonly also deliver ventilation air as part of the supply air.

Air ducting pipes are typically made of metal or plastic, and they are available in a variety of sizes and shapes. The size of the pipe will depend on the amount of air that needs to be transported, and the shape of the pipe will depend on the layout of the HVAC system.

Air ducting pipes are important components of HVAC systems because they allow the air to be distributed throughout the building in a controlled manner. The type of air ducting pipe that is used will depend on the specific requirements of the HVAC system.

Here are some of the most common types of air ducting pipes:

- Metal ducting pipes: Metal ducting pipes are made of materials such as steel, aluminum, or copper. They are strong and durable, and they can withstand high temperatures. Metal ducting pipes are a good choice for applications where there is a risk of fire or corrosion.

- Plastic ducting pipes: Plastic ducting pipes are made of materials such as PVC, ABS, or polyethylene. They are lightweight and easy to install, and they are less expensive than metal ducting pipes. Plastic ducting pipes are a good choice for applications where cost is a factor.

- Flexible ducting pipes: Flexible ducting pipes are made of materials such as fiberglass or rubber. They are flexible and can be easily bent to fit around obstacles. Flexible ducting pipes are a good choice for applications where there are tight spaces or where the ductwork needs to be moved frequently.

Air ducting pipes are an important part of HVAC systems, and they play a vital role in ensuring that the air is distributed throughout the building in a controlled manner. The type of air ducting pipe that is used will depend on the specific requirements of the HVAC system.

Conclusion

Ducting pipes are integral components of ventilation systems, enabling the smooth and efficient movement of air and gases. Understanding the different types, materials, installation techniques, and maintenance requirements is crucial for ensuring optimal performance and a healthy indoor environment. By considering the specific needs of your space and following best practices, you can achieve a well-designed and effective ducting system.