In the realm of plumbing, gardening, landscaping, irrigation, and even some industrial applications, hose connectors play a crucial role in ensuring efficient water management. Knowing about hose connectors will help with the proper selection of the item. In this article, we’ll dive into the world of hose connectors, exploring their types, uses, and providing valuable tips for choosing and maintaining them.

What is a Hose Connector?

A hose connector is a device used to join or attach two sections of a hose together or to connect a hose to a different component, such as a faucet, sprinkler, nozzle, or another hose. These connectors are essential in various applications where fluid, usually air or water, needs to be transferred efficiently and effectively. Hose connectors are designed to create a secure, leak-free connection that ensures the smooth flow of water from one point to another.

Hose connectors come in a variety of types, shapes, and sizes to accommodate different needs and scenarios. They are typically made from materials like plastic, brass, stainless steel, or other durable materials that can withstand the rigors of outdoor and water-related environments. They are also sometimes known as Joiners or Adapters.

Purpose of Hose Connectors

The main purpose of a hose connector is to establish a reliable and watertight connection between hoses and other equipment, allowing users to:

- Easily Switch Attachments: Hose connectors enable users to quickly change between different watering tools, such as nozzles, sprinklers, and spray guns, without the need for complicated installations.

- Extend Hose Length: When a single hose isn’t long enough to reach a specific area, connectors can be used to link multiple hoses together, effectively extending the reach.

- Create Splitter Connections: Hose connectors can be used to split a single water source into multiple hoses or attachments, allowing simultaneous watering in different areas.

- Adapt to Different Components: Hose connectors enable users to connect hoses to various components, such as faucets, water pumps, and irrigation systems, ensuring a versatile water distribution network.

- Maintain System Integrity: Well-designed hose connectors help prevent leaks and water wastage, contributing to efficient water management and conservation.

Types of Hose Connectors

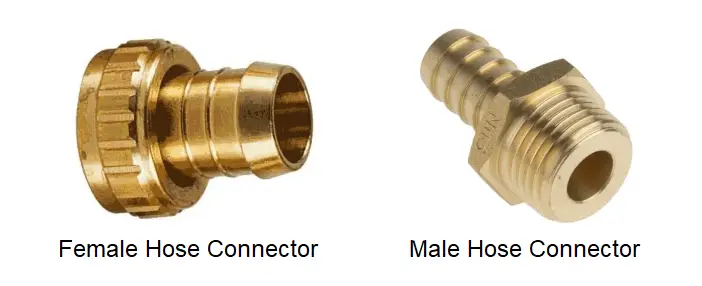

Traditionally, hose connectors adhere to a gender classification – male and female – denoting their method of attachment to hoses or each other during use. This attachment can occur through either insertion (male) or encirclement (female).

These two genders of hose connectors encompass various subtypes. Female hose connectors are accessible in both male-to-female and female-to-female configurations, and there’s even a dual-female design for simultaneously connecting two compatible connectors. On the other hand, male hose connectors are available in both male-to-female and male-to-male variations.

Within this overarching categorization, there exist numerous designs tailored for specific purposes, each with distinctive features. These encompass adjustable nozzles, adapters, inserts, and valves. Furthermore, a comprehensive spectrum of liquid pressures is at one’s disposal, ranging from 4.2 bar all the way up to 390 bar.

The most common types of hose connectors are explained below:

Air Hose Connectors:

Air hose connectors are fittings designed to establish secure connections between air hoses and various pneumatic devices, tools, or systems that rely on compressed air for operation. These connectors facilitate the smooth and efficient flow of compressed air, ensuring that it reaches its intended destination without leaks or disruptions. Air hose connectors come in various types and sizes to accommodate different air pressure requirements and application needs, such as in industries like manufacturing, construction, automotive, and more.

Water Hose Connectors:

Water hose connectors are devices used to join or attach sections of water hoses together or to connect hoses to different water-related components, like faucets, sprinklers, nozzles, or other hoses. These connectors ensure a secure and watertight connection, allowing for the effective distribution of water in applications such as gardening, irrigation, car washing, and industrial processes. Water hose connectors come in different forms to accommodate various hose sizes and attachment methods, and they play a crucial role in preventing leaks and maintaining water efficiency.

Hydraulic Hose Connectors:

Hydraulic hose connectors, also known as hydraulic fittings, are essential components used in hydraulic systems to connect hoses, pipes, and tubes while maintaining a leak-free and high-pressure connection. These connectors are vital for transmitting hydraulic fluid between various components, such as pumps, valves, cylinders, and motors. Hydraulic hose connectors come in a variety of styles, including threaded, quick-release, and crimped connectors, to match different system requirements and ensure the safe and reliable operation of heavy machinery, construction equipment, and other applications that rely on hydraulic power.

Garden Hose Connector:

A garden hose connector is a fitting that enables the attachment of a garden hose to other garden-related equipment or accessories. It allows for easy and secure connection between the hose and devices such as sprinklers, nozzles, spigots, and other watering tools. Garden hose connectors come in various shapes and sizes to ensure compatibility with different hose types and applications, and they are designed to prevent leaks and facilitate efficient water flow for gardening and landscaping tasks.

Quick Hose Connector:

A quick hose connector, also known as a quick-release hose connector, is a type of fitting designed for rapid attachment and detachment of hoses and accessories. It features a mechanism that allows users to connect hoses without the need for threading or tools. Quick hose connectors are commonly used in scenarios where frequent changes between watering tools or attachments are necessary, saving time and effort.

Heater Hose Connector:

A heater hose connector is a component used in automotive cooling systems to connect heater hoses to the engine’s cooling system. These connectors enable the flow of coolant to the vehicle’s heater core, which then heats the cabin air. Heater hose connectors ensure a secure and leak-free connection between the hoses and the engine, allowing for effective climate control inside the vehicle.

Sink Hose Connector:

A sink hose connector is a fitting used to attach a hose to a sink faucet. It allows users to extend the reach of the faucet for tasks such as filling buckets, cleaning, or washing. Sink hose connectors are particularly useful in kitchens and laundry rooms, where additional water access is required beyond the sink’s regular spout.

Cooling Hose Connector:

A cooling hose connector is a fitting used in automotive cooling systems to link various components, such as radiator hoses, thermostat housings, and water pumps. These connectors ensure the proper circulation of coolant throughout the engine, preventing overheating and maintaining optimal operating temperatures.

Washer Hose Connector:

A washer hose connector is a fitting used to attach hoses to washing machines. It connects the water supply lines to the washing machine, allowing water to enter the machine for laundry purposes. Washer hose connectors are designed to prevent leaks and ensure a secure connection to prevent water wastage during laundry cycles.

Y Hose Connector:

A Y hose connector, also known as a hose splitter or hose Y adapter, is a device that divides a single water source into two or more hoses. It features a Y-shaped design that allows multiple hoses or attachments to be connected simultaneously. Y hose connectors are commonly used in gardening and outdoor watering scenarios to distribute water to different areas or devices from a single source.

Again based on the material of construction of the hose connectors they can are classified with the material name as follows:

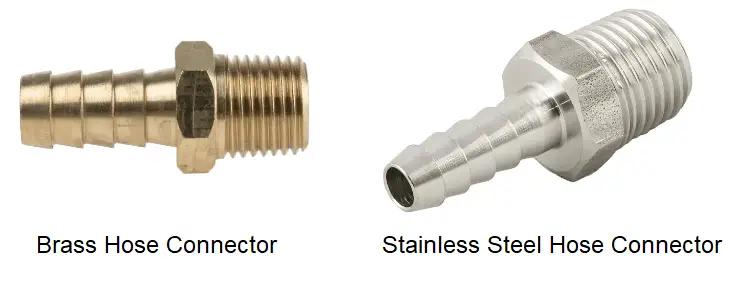

Brass Hose Connectors:

Brass hose connectors are fittings made from brass, a copper-zinc alloy known for its durability, corrosion resistance, and malleability. These connectors are widely used in various applications due to their robust nature and ability to withstand exposure to water and outdoor elements. Brass hose connectors are commonly used in garden hoses, plumbing systems, and industrial settings where reliable connections are crucial.

Aluminium Hose Connectors:

Aluminum hose connectors are fittings crafted from aluminum, a lightweight and corrosion-resistant metal. While not as common as other materials, aluminum connectors are used in certain applications where weight is a concern. They are suitable for lightweight hoses and are often chosen for their resistance to rust and durability.

Steel Hose Connectors:

Steel hose connectors are fittings made from steel, a strong and robust metal. These connectors are used in a variety of industrial applications, such as high-pressure systems and heavy-duty equipment, due to their strength and resilience. Steel hose connectors are available in various types, including carbon steel and stainless steel, each with specific benefits based on the intended application.

Stainless Steel Hose Connectors:

Stainless steel hose connectors are fittings crafted from stainless steel, an alloy known for its exceptional corrosion resistance and strength. These connectors are particularly suitable for applications involving exposure to moisture or harsh chemicals. Stainless steel hose connectors are commonly used in marine environments, food processing, pharmaceuticals, and chemical industries.

Plastic Hose Connectors:

Plastic hose connectors are fittings made from various types of plastic materials, such as PVC (polyvinyl chloride) or ABS (acrylonitrile butadiene styrene). Plastic connectors are lightweight, affordable, and resistant to corrosion. They are often used in casual gardening, household tasks, and situations where weight and cost are considerations. However, plastic connectors may not be as durable as metal alternatives in high-pressure or heavy-duty applications.

Hose Connectors are also classified by their Thread Type as follows:

NPT Hose Connectors:

NPT stands for National Pipe Thread and refers to a type of thread standard used in North America for pipe and hose connections. NPT hose connectors feature tapered threads that create a seal by compressing the threads together. They are widely used in plumbing, industrial, and fluid-handling applications in the United States and Canada. NPT connectors are available in both male and female versions and are known for their ease of assembly and leak-resistant characteristics.

BSPT Hose Connectors:

BSPT stands for British Standard Pipe Taper and is a threaded standard used in the United Kingdom and other countries. BSPT hose connectors also have tapered threads, but they differ from NPT threads in terms of angle and pitch. BSPT connectors are often found in European and Commonwealth countries for various fluid and gas applications. Like NPT, BSPT connectors come in male and female versions and provide reliable sealing through thread compression.

BSPP Hose Connectors:

BSPP stands for British Standard Pipe Parallel and is another thread standard used in the United Kingdom and some other regions. Unlike tapered threads, BSPP threads are parallel, which means they do not create a seal through thread compression but rely on additional sealing methods like O-rings or gaskets. BSPP hose connectors are commonly used in applications where a secure connection is required, often in hydraulic and pneumatic systems, but without the need for a tapered thread seal.

Uses of Hose Connectors

Hose connectors find applications in a wide range of industries and scenarios where fluid transfer, distribution, and control are essential. Some of the common applications of hose connectors include:

Gardening and Landscaping:

Hose connectors are crucial in gardens and landscapes to attach hoses to various watering tools such as sprinklers, nozzles, and soaker hoses, enabling efficient irrigation and plant care.

Industrial Processes:

In industries like manufacturing and construction, hose connectors are used to connect hoses to equipment, machinery, and tools for processes such as coolant circulation, pneumatic systems, and hydraulic operations.

Automotive and Transportation:

Hose connectors play a vital role in vehicle cooling systems, connecting hoses to radiators, water pumps, and heaters. They are also used in hydraulic brake systems and air conditioning.

Home Maintenance:

In household chores, hose connectors are used to attach hoses to pressure washers, washing machines, and outdoor cleaning equipment, facilitating tasks like car washing and deck cleaning.

Irrigation and Agriculture:

Hose connectors are essential in irrigation systems for fields and crops, ensuring water distribution to various sections of the land. They connect hoses to sprinklers, drip lines, and other irrigation components.

Construction and Mining:

In construction and mining industries, hose connectors are used in heavy machinery and equipment for tasks like transferring water, fuels, and hydraulic fluids.

Marine and Boating:

In marine applications, hose connectors connect hoses for bilge pumping, cooling systems, and other water-related functions on boats and ships.

Food and Beverage Industry:

Hose connectors made from food-grade materials are used to transfer liquids in the food and beverage industry, maintaining hygiene standards in processes like beverage production and liquid transfer.

Chemical and Pharmaceutical Industry:

Specialty hose connectors are used in chemical and pharmaceutical industries to transfer fluids safely, ensuring compatibility with the materials being handled.

Firefighting and Emergency Services:

Hose connectors are essential components in firefighting equipment, enabling quick and secure connections between hoses and fire hydrants, pumps, and nozzles.

HVAC Systems:

In heating, ventilation, and air conditioning (HVAC) systems, hose connectors are used to connect hoses for coolant circulation, drainage, and other fluid-related functions.

Pool and Spa Maintenance:

Hose connectors are used to connect hoses to pool and spa equipment, facilitating water circulation, cleaning, and maintenance.

Basically, Hose couplings and connectors are required whenever a hose needs to be firmly attached to a liquid, air, or even moving granulated solids like flour, wheat, or sugar. Typical examples might include:

- Kitchen or external taps for watering greenery and gardens

- Industrial cooling systems

- Water sprinklers

- Pumps

- Pressure washers

- Industrial water guns

- Spigots

- Heating, ventilation, and air conditioning systems

- Bulk transfer of granular particles

- Ink transfer systems within the printing industry

Hose Connector Sizes

Hose connectors can be categorized into three main size categories: mini, small, and large. These size classifications pertain to the central tube’s diameter width and range from as small as half an inch (0.53 inches) up to 50mm (2.01 inches). Some frequently encountered inner diameter measurements include:

- 15mm (0.59 inches)

- 19mm (three-quarters of an inch)

- 25.4mm (one inch)

Tips for Choosing and Maintaining Hose Connectors

- Material Matters: Hose connectors can be made from various materials, including plastic, brass, and stainless steel. Consider the application and environment to choose the best material for longevity and compatibility.

- Size and Compatibility: Ensure that the connectors you choose are compatible with your hoses, nozzles, and other accessories. Common sizes are ¾ inch and 5/8 inch, but variations exist.

- Regular Inspection: Check your connectors for any signs of wear, cracking, or leakage regularly. Replace damaged connectors promptly to prevent water wastage and inefficiency.

- Proper Storage: To prolong the lifespan of your hose connectors, store them indoors during the colder months to prevent freezing and potential damage.

- Use Lubrication: Applying a small amount of lubricant, like a plumber’s tape or grease, can help create a watertight seal and make it easier to attach and detach connectors.

Conclusion

Hose connectors might seem like small components, but they play a significant role in ensuring effective water distribution, whether you’re tending to your garden or using industrial equipment. Understanding the types of connectors, and their applications, and following maintenance tips can save you from leaks, water wastage, and potential frustration. So, whether you’re a green-thumbed gardener or a homeowner maintaining your property, hose connectors are tools that deserve attention and care.