Pipeline cleaning refers to the process of removing contaminants and debris from the inside of pipelines that are used to transport fluids such as water, oil, and gas. Over time, pipelines can accumulate sediment, scale, rust, and other materials that can reduce their efficiency and lifespan.

Pipeline cleaning typically involves the use of specialized equipment and techniques, such as high-pressure water jetting or chemical cleaning agents, to dislodge and remove these materials. The cleaning process is often conducted in stages, with an initial inspection to determine the extent of the buildup, followed by the selection of appropriate cleaning methods and equipment, and finally, a post-cleaning inspection to ensure that the pipeline is free of debris and functioning properly.

Regular pipeline cleaning is an important maintenance activity for ensuring the safe and efficient operation of pipelines and reducing the risk of pipeline failure or environmental damage.

How to Clean Pipelines?

Cleaning pipelines typically involves several steps and may vary depending on the type of pipeline and the materials that need to be removed. Here are some general steps that may be involved in cleaning pipelines:

- Inspection: The first step is to inspect the pipeline to determine the extent of buildup or damage. This can be done using various inspection techniques such as video cameras, ultrasonic testing, or magnetic flux leakage.

- Select cleaning method: Depending on the type and extent of buildup, the appropriate cleaning method can be selected. Some common cleaning methods include:

- Mechanical cleaning: This involves the use of mechanical devices such as scrapers or pigs to remove debris from the pipeline walls.

- Chemical cleaning: Chemicals are used to dissolve or loosen buildup and contaminants, which can then be flushed out of the pipeline using water or air.

- High-pressure water jetting: This involves the use of high-pressure water to dislodge and remove debris from the pipeline walls.

- Cleaning process: Once the cleaning method is selected, the cleaning process can begin. The pipeline is typically isolated and the cleaning equipment is inserted into the pipeline. The cleaning process may involve multiple passes with the equipment, and may also involve the use of chemicals or other cleaning agents.

- Inspection: After the cleaning process is complete, the pipeline is inspected again to ensure that all debris has been removed and the pipeline is functioning properly.

Overall, pipeline cleaning is a complex and specialized process that requires careful planning, specialized equipment, and experienced operators. It is important to follow appropriate safety procedures and to work with trained professionals to ensure the safe and effective cleaning of pipelines.

What are the Methods of Industrial Pipeline Cleaning?

There are several methods that can be used for industrial pipeline cleaning, and the selection of the appropriate method depends on the type and extent of buildup or contaminants in the pipeline. Some common methods of industrial pipeline cleaning include:

- Mechanical cleaning: This method involves the use of mechanical devices such as pigs, scrapers, or brushes to physically remove buildup and debris from the pipeline walls. Mechanical cleaning is often used in pipelines with heavy deposits or hard-to-remove materials.

- Chemical cleaning: Chemical cleaning involves the use of cleaning agents, such as acids or solvents, to dissolve or loosen buildup and contaminants, which can then be flushed out of the pipeline using water or air. This method is often used for pipelines with organic or inorganic deposits, such as scale or rust.

- High-pressure water jetting: This method uses high-pressure water to dislodge and remove debris from the pipeline walls. Water jetting is effective for removing soft deposits, such as sludge or mud, and can be used for cleaning pipes of various sizes and materials.

- Ultra-high-pressure water jetting: This method uses even higher-pressure water (typically above 20,000 psi) to remove very hard and stubborn deposits, such as concrete or hardened scale. This method requires specialized equipment and trained operators.

- Vacuum cleaning: This method uses a vacuum truck or other suction device to remove debris and contaminants from the pipeline. Vacuum cleaning is often used for pipelines with loose or granular materials, such as sand or gravel.

- Foam cleaning: This method involves the use of a cleaning foam that is injected into the pipeline to loosen and remove buildup and contaminants. The foam is then flushed out of the pipeline using water or air.

Overall, the selection of the appropriate pipeline cleaning method depends on several factors, including the type and extent of buildup or contaminants, the size and material of the pipeline, and the desired cleaning outcome. It is important to work with trained professionals to ensure the safe and effective cleaning of industrial pipelines.

How to Choose a Pipeline Cleaning Method?

Choosing the right pipeline cleaning method is important for effective and efficient cleaning, and the selection of the appropriate method depends on several factors. Here are some considerations when choosing a pipeline cleaning method:

- Type of buildup: The type of buildup or contaminants in the pipeline will determine the most effective cleaning method. For example, mechanical cleaning may be appropriate for hard deposits like scale, while chemical cleaning may be best for organic materials like oil or grease.

- Pipeline size and material: The size and material of the pipeline will also influence the choice of cleaning method. For example, high-pressure water jetting may be suitable for small-diameter pipes made of soft materials like plastic or rubber, while ultra-high-pressure water jetting may be required for larger-diameter pipes made of hard materials like steel.

- Environmental considerations: Considerations such as water availability, wastewater treatment, and potential environmental impact should also be taken into account when choosing a pipeline cleaning method.

- Safety considerations: Pipeline cleaning can be a hazardous process, and safety should always be a top priority. Considerations such as operator training, personal protective equipment, and safe handling of chemicals or high-pressure equipment should be taken into account when choosing a pipeline cleaning method.

- Cost and time considerations: The cost and time required for pipeline cleaning should also be considered when choosing a cleaning method. For example, some methods may require more equipment or specialized operators, which can increase the cost of cleaning.

Overall, the selection of the appropriate pipeline cleaning method requires careful consideration of several factors. It is important to work with experienced professionals who can help determine the best method for your specific pipeline cleaning needs.

Is Pigging the most efficient method for Pipeline Cleaning?

Pigging can be a highly efficient method for pipeline cleaning, especially for pipelines with heavy deposits or hard-to-remove materials. The use of pigs, which are cylindrical or spherical devices that are inserted into the pipeline and propelled by fluid flow, can help remove debris and buildup from the pipeline walls.

One advantage of pigging is that it can be used for both cleaning and inspection, as some pigs are equipped with cameras or sensors that can detect pipeline defects or damage. Pigging is also a relatively fast method of cleaning, as it can be performed while the pipeline is still in operation.

However, pigging may not be suitable for all pipeline cleaning needs. For example, pigging may not be effective for removing soft deposits like sludge or mud, and may not be appropriate for pipelines with complex geometry or multiple bends. Additionally, pigging requires specialized equipment and trained operators, which can increase the cost of cleaning.

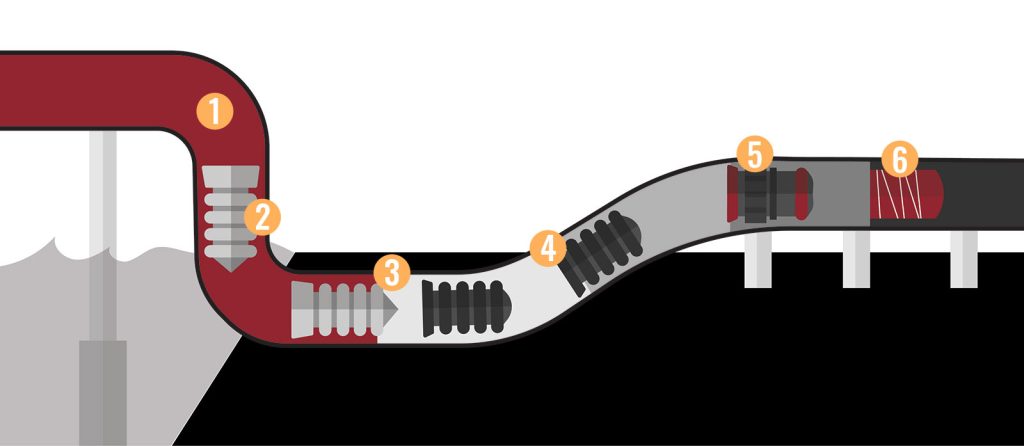

Overall, while pigging can be an efficient method for pipeline cleaning in certain situations, the selection of the appropriate cleaning method depends on several factors, including the type and extent of buildup, the size and material of the pipeline, and the desired cleaning outcome. It is important to work with experienced professionals to determine the best method for your specific pipeline cleaning needs. Fig. 1 (Image Credit: https://internalpipeline.com/pipeline-cleaning/ )below shows a typical schematic of pipeline cleaning using PIGs.

What is swabbing in pipeline cleaning?

Swabbing is a pipeline cleaning method that involves using a soft, flexible cylinder (known as a “swab”) to remove debris, liquids, or other contaminants from the inside of a pipeline. The swab is typically made of foam, rubber, or other materials that are compatible with the pipeline contents.

The swabbing process involves inserting the swab into the pipeline and then using pressure to propel it through the pipeline, either by pumping it or by using the pipeline’s own fluid flow. As the swab moves through the pipeline, it picks up and removes debris and liquids from the walls of the pipeline.

Swabbing is often used in pipelines where other cleaning methods, such as pigging or flushing, are not effective or practical. It is also used as a pre-cleaning method prior to pigging or flushing to remove large debris or obstructions that could damage the pig or block the flushing process.

Swabbing can be used in pipelines that transport a variety of materials, including oil, gas, water, and chemicals. It is a relatively low-cost and simple method of pipeline cleaning that can be performed quickly with minimal disruption to the pipeline’s operations. However, it may not be as effective as other cleaning methods for removing stubborn deposits or for cleaning long or complex pipelines.

What is Ice Pigging?

Ice pigging is a pipeline cleaning method that uses a slush of ice and water to remove debris and contaminants from the inside of a pipeline. The ice slurry is pumped into the pipeline and propelled through it by the flow of water. As the slurry moves through the pipeline, it scrubs the walls and removes debris, leaving the pipeline clean.

Ice pigging is particularly effective for removing soft or sticky deposits, such as biofilms, fats, and oils, which can be difficult to remove with other cleaning methods. It can also be used to remove hard deposits, such as scale and mineral build-up, although multiple passes may be required to fully clean the pipeline.

The ice slurry used in ice pigging is typically made by freezing water and then crushing the ice into small pieces. The ice is mixed with water to create a slushy mixture that is pumped into the pipeline. The ice melts as it moves through the pipeline, leaving behind a small amount of water that can be easily removed.

Ice pigging is a relatively new and innovative pipeline cleaning technique that has several advantages over traditional cleaning methods, such as pigging and flushing. It is a low-risk, non-intrusive method that does not require the use of chemicals or abrasive materials. It is also a highly efficient method that can clean pipelines more thoroughly and in less time than other methods.

Ice pigging has been successfully used in a variety of industries, including water treatment, oil and gas, and food and beverage production. It is especially useful for cleaning pipelines in sensitive environments where the use of chemicals or abrasive materials is not allowed.

What is Pipeline Cleaning Service?

Pipeline cleaning services refer to a range of specialized services that are focused on cleaning and maintaining pipelines used in various industries such as oil and gas, petrochemicals, food and beverage, water and wastewater, and others.

Pipeline cleaning services involve the use of various techniques, equipment, and cleaning agents to remove debris, buildup, and other contaminants from the pipeline walls and internal surfaces. The main goal of pipeline cleaning services is to ensure that pipelines remain free of obstruction and buildup, which can cause reduced flow rates, decreased efficiency, and other operational issues.

Pipeline Cleaning Service Companies

There are several reputed companies that offer pipeline cleaning services, including:

- Baker Hughes – a leading provider of oilfield services, Baker Hughes offers pipeline cleaning services for the oil and gas industry, using a range of methods including chemical cleaning, high-pressure water jetting, and pigging.

- SUEZ – a global environmental services company, SUEZ provides pipeline cleaning services for the water and wastewater industry, using methods such as high-pressure water jetting and vacuum cleaning.

- Clean Harbors – a provider of environmental, energy, and industrial services, Clean Harbors offers pipeline cleaning services for various industries, including oil and gas, petrochemicals, and pharmaceuticals.

- MPW Industrial Services – a provider of industrial cleaning and maintenance services, MPW offers pipeline cleaning services using a range of methods such as chemical cleaning, high-pressure water jetting, and pigging.

- Envirosystems – a provider of environmental and industrial services, Envirosystems offers pipeline cleaning services using methods such as chemical cleaning, high-pressure water jetting, and vacuum cleaning.

- HydroChemPSC – a provider of industrial cleaning and environmental services, HydroChemPSC offers pipeline cleaning services using a range of methods such as chemical cleaning, high-pressure water jetting, and pigging.

These are just a few examples of companies that offer pipeline cleaning services. It is important to research and evaluate potential service providers to ensure that they have the experience, expertise, and equipment necessary to meet your specific pipeline cleaning needs.

I would love to have your material on pipeline engineering

Examples too

1….pipeline installation

2….pipeline inspection

3…. pipeline maintenance

4…… pipeline cleaning

5….. stress analysis

Not long ago, I heard that my uncle’s in charge of keeping an industrial plant in good shape, and he’s currently looking for a professional team to clean and unclog its pipelines. It’s good to know that we’d consider the type of building before choosing a pipeline cleaning method. I’m sure my uncle will find your post very helpful.