As piping constitutes a major chunk of any refinery, chemical, petrochemical, or power generating industries there is always a need of purchasing various piping and mechanical items. There must be an approved procurement procedure for the smooth functioning of this process and receiving items in the construction site without much delay. In this article, We will explore the major Steps involved during the Procurement/Purchase Process of piping/mechanical items for the Oil and Gas Industry.

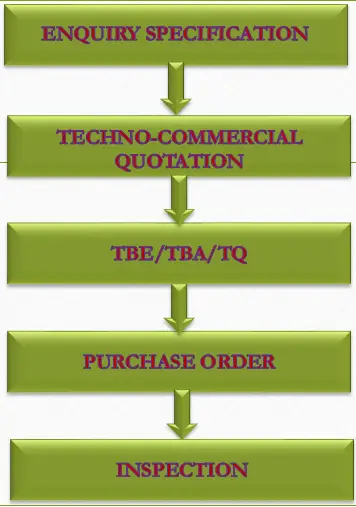

Many types of equipment and items need to be purchased in the piping project from different vendors/suppliers. Before finalization of the vendor/ supplier to get the pipe material, there are many phases/ steps which need to be followed as mentioned below:

In the first step, an inquiry specification (normally specifications specifies all technical requirements, preliminary drawings, quality requirements, etc.) for the required equipment/item is floated to several different vendors to get a techno-commercial quotation. Normally each company has a list of approved vendors. The inquiry is generally sent to the approved vendors/ suppliers. In case the item is not available with the approved vendors then other vendors are requested to go through the approval procedure and they are included in the approved vendor list.

Based on the specification mentioned in the purchase requisition (PR) Vendors prepare an offer and send it. After receiving offers from the different vendors/suppliers, each offer is checked and evaluated from a technical viewpoint first and then a cost point. If there are any changes/deviations or if there are points that the vendor has not confirmed, it has to be clarified through technical queries/TQ. This process may take a few days to complete.

After receiving the replies to all the technical queries and the deviation request from the suppliers the originating engineer will decide if the vendor is technically suitable for that particular inquiry. He may select several vendors as suitable based on technical and qualitative requirements.

The specification engineer then populates the replies of all the vendors/suppliers in a common document (normally in an excel sheet) which is called the technical bid analysis (TBA)/ evaluation (TBE) report. This document will show the major/impact points of the particular inquiry along with the replies from all the vendors/suppliers. If there are any deviations they are mentioned against applicable points in the TBA/TBE. In the TBA/TBE Specification engineer has to give a technical acceptance or rejection of each vendor/supplier in the inquiry. This TBA/TBE report is then forwarded to the projects/procurement/purchase department for further action at their end.

After receiving the TBA/TBE, the projects/procurement departments then evaluate the technically accepted vendor for commercial and delivery schedules. The vendor/supplier which is acceptable in technical, commercial, and delivery schedule terms is given the purchase order (PO).

After the purchase order (PO) has been placed/initiated with a vendor then the selected supplier sends the final drawing and documentation for review and approval. The originating engineer will review the drawing and documentation along with the datasheet and the inquiry specifications send to and agreed upon by the vendor/supplier. If there are any comments or any points which need to be added to the vendor drawing then the engineer can mark it up in the drawing or document and send it back to the vendor/supplier for incorporation. Once all the comments are been taken care of, then the drawing and the document can be accepted.

Once the drawing is accepted the materials go into the fabrication shop and they are prepared and ready for inspection. Inspection is carried out as mentioned in the datasheet/inquiry specification.

After the inspection, the material is then ready for dispatch to the site location as per schedule. Along with the item, the vendor has to send all quality and test reports. All ordered items normally bear a warranty of at least one year of successful operation after installation.

By chance I found this fantastic website about piping and stress analysis. Hopefully the author keeps the good working, which is very beneficial to us. 🙂

Cheers !

No technical Parameter you given in Piping procurement.

like code,standard, and material.

Page Material Code Gasket details

1 ПМБ ГОСТ 481-80 8″

2 ПМБ ГОСТ 481-80 4″

3 ПМБ ГОСТ 481-80 6″ 4″ 2″

4 ПМБ ГОСТ 481-80 10″

5 ПМБ ГОСТ 481-80 10″

6 ПМБ ГОСТ 481-80 2″

7 ПМБ ГОСТ 481-80 3″ 3″

8 ПМБ ГОСТ 481-80 2″

9 ПМБ ГОСТ 481-80 2″

10 ПМБ ГОСТ 481-80 2″

11 ПМБ ГОСТ 481-80 (PTFE 150#) 10″ 5″ 10″

12 ПМБ ГОСТ 481-80 (PTFE 150#) 10″ 5″ 10″

13 ПМБ ГОСТ 481-80 (PTFE 150#) 10″ 10″

14 ПМБ ГОСТ 481-80 (PTFE 150#) 10″ 10″

15 ПМБ ГОСТ 481-80 1″

16 ПМБ ГОСТ 481-80 1″

*Regarding the gaskets we don’t have the details, because these gaskets comes under the vendor scope. So we need to check and confirm with the vendor to provide the gaskets and details (item code) to use in future.

*Regarding the PTFE gaskets we have the material class PTFE 150 RF ASME 16.5 gasket (150#), so we can use this item code.