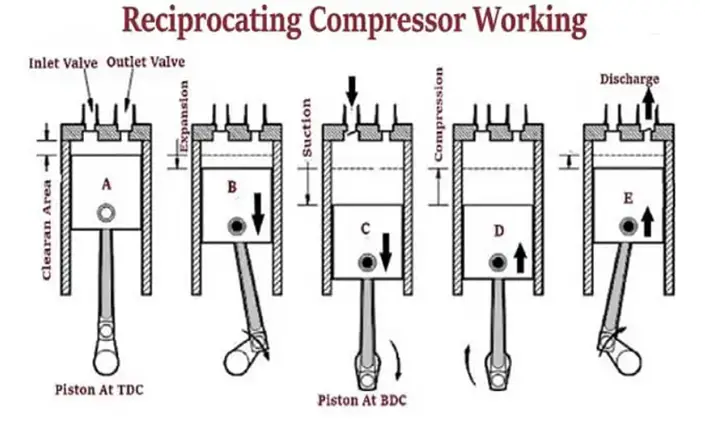

A reciprocating compressor is a kind of positive displacement compressor that compresses and delivers air or gas at high pressure using a reciprocating component, such as a piston or plunger. The piston of the reciprocating compressor moves forward and backward, compressing the gas or air. For this reason, another name for it is a piston compressor. The gas or air in this compressor is drawn into the chamber and compressed by a reciprocating piston. The working fluid volume is moved by this piston to function. Applications requiring both high gas pressure and low flow rate are often served by reciprocating air compressors. Fig. 1 below shows the working of a reciprocating compressor.

Codes and Standards for Reciprocating Compressor:

Various codes and standards govern the design and manufacture of reciprocating compressors:

- API Standards: API-11P (Packaged Reciprocating Compressors) and API-618 (Reciprocating Compressors for Petroleum, Chemical, and Gas Industry Services)

- ISO Standards: ISO-13707 and ISO-13631

- Shell DEP: DEP 31.29.40.31

- API RP 688 for Pulsation and Vibration Control

Reciprocating Compressor Sizing:

Reciprocal compressor sizing has been a task for many decades. Engineers, packagers, and end users can benefit from the robust sizing software offered by the majority of reciprocating compressor OEMs nowadays. However, these sizing tools might produce inappropriate and deceptive hardware suggestions if not used carefully and with attention to detail.

A typical compressor sizing methodology proceeds as follows:

- Inlet and discharge pressures and a desired flow rate are specified by the Client.

- A gas analysis or equivalent is specified by the Client.

Steps for selecting the proper compressor:

- Calculate the compression ratio.

- Choose the number of stages of the compressor.

- Calculate Estimated BHP.

- Calculate estimated Discharge Pressure.

- Calculate the discharge temperature.

- Determine the suction volumetric efficiency.

- Calculate the required piston displacement.

- Determine the Velocity of Valves

- Determine the Gas rod loads.

- Selecting of Reciprocating Compressor cylinder and Frame by using the OEM Design Data

OEMs typically carry out steps 1 through 10 using sophisticated software, however hand calculations are frequently sufficient.

Step 1: Calculate the Compression Ratio (CR):

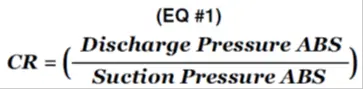

A single-stage compressor has only a single R-value. Whereas a typical two-stage compressor has three R values.

- CR (or) R = total compression ratio for the compressor

- R1 = compression ratio for the first stage

- R2 = compression ratio for the second stage

R = Pd/Ps, R1 = Pi/Ps, R2 = Pd/Pi

Here,

- Ps=Suction pressure,

- Pd=Discharge pressure,

- Pi=Interstage pressure – the pressure between the 1st and 2nd stages of the compressor.

Step 2: Calculate / Choose no. of stages of the compressor:

The number of stages can also be determined using the thumb rule, which is shown in Fig. 2, however, it depends on the OEMs.

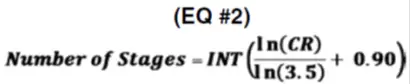

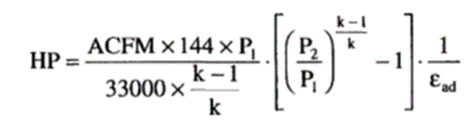

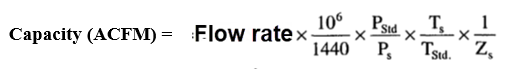

Step 3: Calculate Estimated Power (BHP):

Where, Ƹad = Volumetric adiabatic Efficiency (From Figure 3); k = specific heat of the gas. Compression Ratio R= (P2/P1); Flow Rate (MMSCFD)

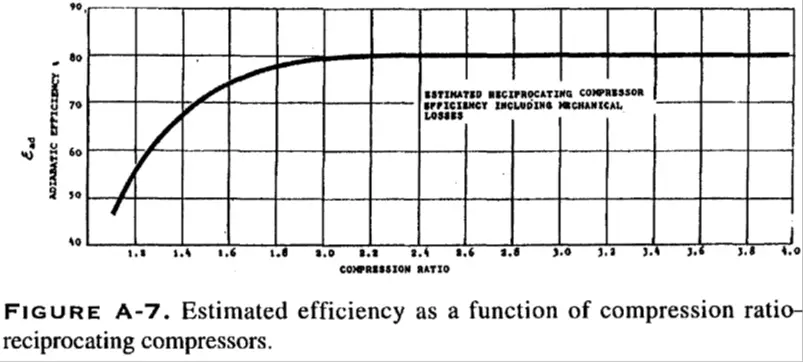

Step 4: Calculate estimated Discharge Pressure (Psia)

It is crucial to estimate the number of stages, power required, and interstage pressures. Every OEM has a set number of frames and a family of standard cylinders that are predesigned to fit those frames. As a result, the number of possible frame/cylinder combinations is limited. The best option any specific OEM can offer is at least one of the potential combinations.

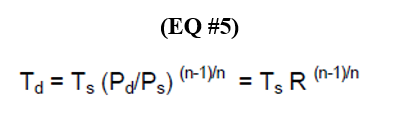

Step 5: Calculate the discharge temperature (oR)

The life of the valves and piston rings is directly impacted by the compressor’s discharge temperature. The discharge temperature of an air-cooled single-stage compressor can be determined using the following formula:

- Ts Suction temperature °R (°K)

- Ps Suction pressure PSIA (Bar-a)

- Pd Discharge pressure PSIA (Bar-a)

- R Compression Ratio (Pd/Ps)

- n specific heat ratio of the gas.

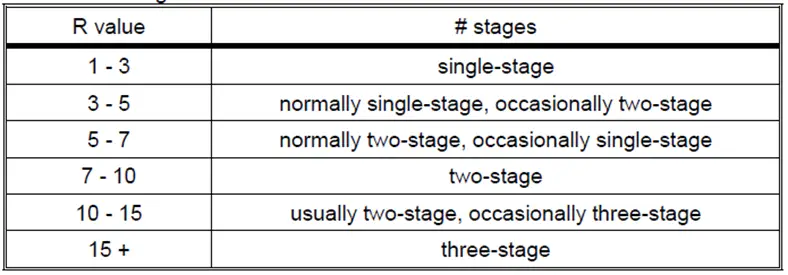

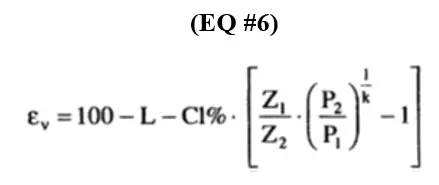

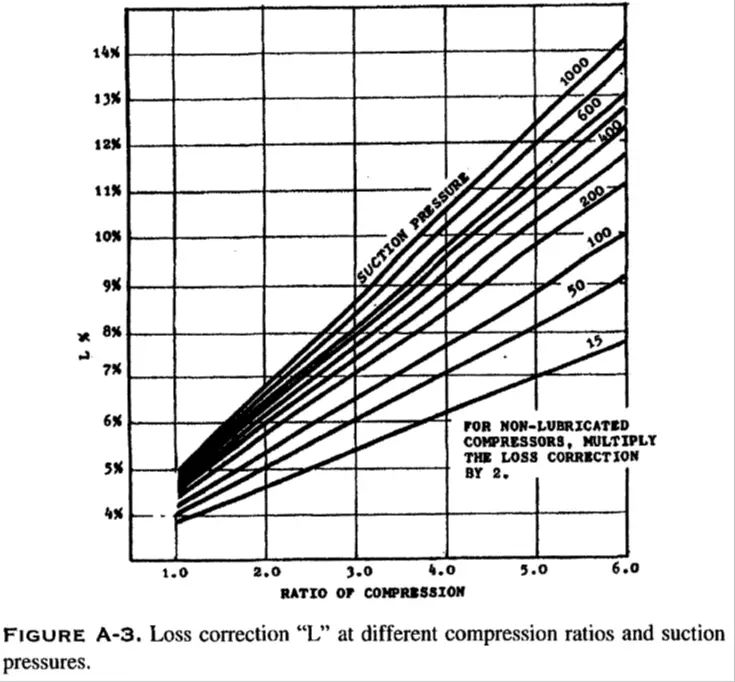

Step 6: Determine the suction volumetric efficiency

Volumetric efficiency includes many factors that help explain the differences between ideal gas behavior and real gas behavior. In general, volumetric efficiency depends upon compression ratio, cylinder clearances, gas compressibility values, and the ratio of specific heats (k or N value) (Z1, Z2, and k values are specified in Gas properties). CL might be 15% (CL = 0.15) for normal cylinders and 65% (CL = 0.65) for pipeline cylinders.

*Where L is taken from Figure 4.

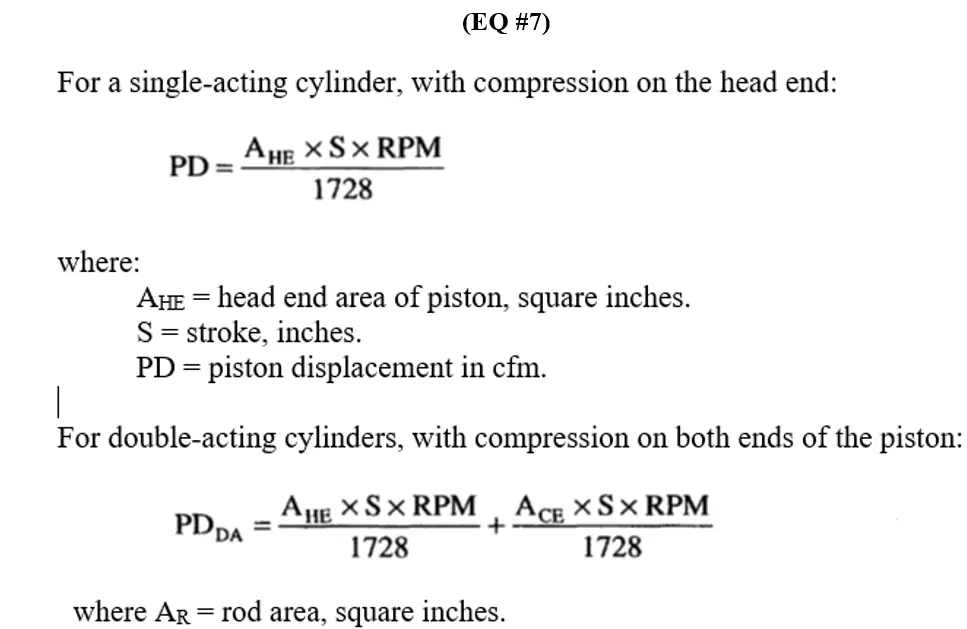

Step 7: Calculate the required piston displacement

Piston displacement is the actual volume displaced by the piston as it travels the length of its stroke from Position 1, bottom dead center, to Position 3, top dead center. Piston displacement is normally expressed as the volume displaced per minute or cubic feet per minute.

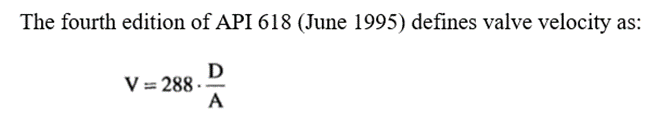

Step 8: Determine the Velocity for Valves

Compressor valves are the most critical part of a reciprocating compressor. Generally, they require the most maintenance of any part. They are sensitive both to liquids and solids in the gas stream, causing plate and spring damage and breakage. When the valve lifts, it can strike the guard and rebound to the seat several times in one stroke. This is called valve flutter and leads to breakage of valve plates.

Where,

- V = average velocity in feet/minute.

- D = cylinder displacement in cubic feet/minute.

- A = total inlet valve area per cylinder, calculated by valve lift times valve opening periphery, times the number of suction valves per cylinder, in square inches.

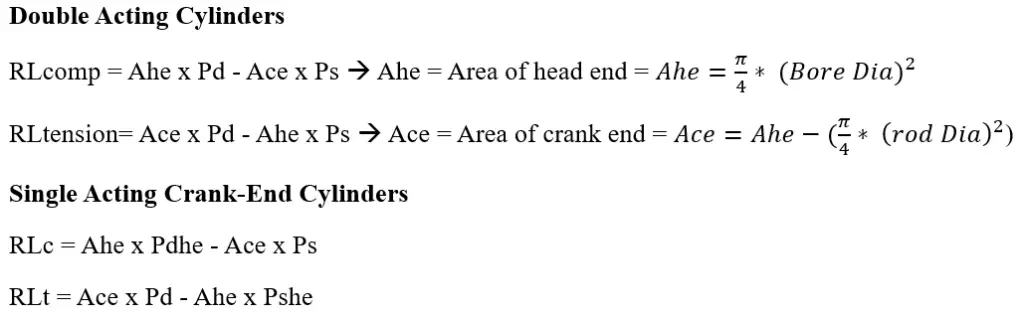

Step 9: Determine the Gas rod loads

Gas rod loads are calculated based on internal cylinder pressures. The equations below are based on pressures in gauge units. If absolute units are applied, then additional terms for Patm being applied on the piston rod diameter must be included.

Thumb Rules for good Compressor sizing:

- Rod loads < 100%

- Rod reversal Degree (Xhd pin degree / % Rvrsl Lbf) > 30% & Force > 25%.

- Cylinder Discharge Temperature < 300oF (Some OEMs allow < 350 oF)

- Volumetric Efficiency >15%

- Discharge Events > 4.5ms; >2.5ms (With Speed Reversal).

- Ideal BHP load is 75-100%

- Pressure Ratio F/F ideally should be < 3:1

Step 10: Selecting of Reciprocating Compressor cylinder and Frame by using the OEM Design Data

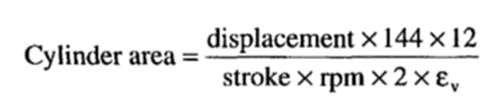

Once the above steps are calculated, use the calculated Volumetric Efficiency, Maximum HP, Displacement, Discharge Temperature, and Gas Rod Loads and check with respective OEMs design data to determine the number of Strokes and speed (RPM). Using these Strokes and speed calculate the Cylinder Area as per below.

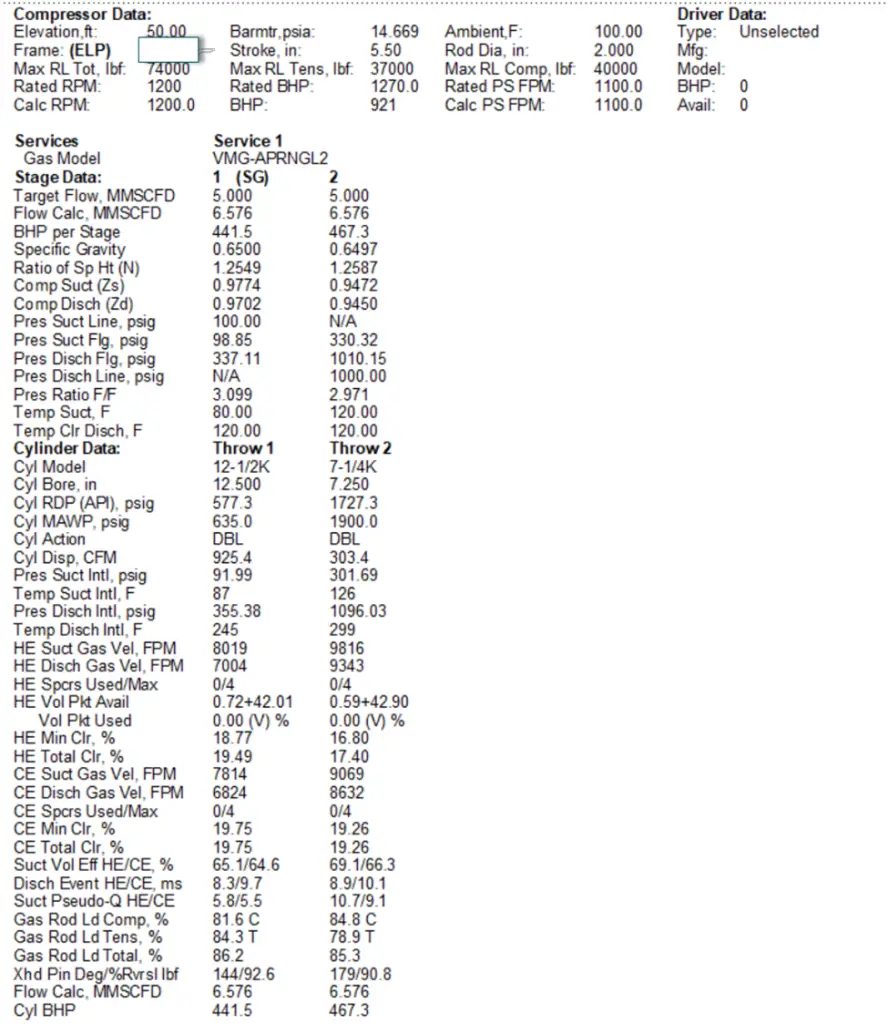

By this, the Cylinder area is determined which helps in finding out the right Cylinder bore and Cylinder model. It also helps us in deciding the number of Cylinders used in the multistage compressor. Attached below is the Performance chart for reference where it satisfies all the user criteria and with cost cost-effective selection of the reciprocating compressor and its frames and cylinder Models.

Thanks Rakesh for step-by-step procedure for compressor sizing