Snow and Ice loading is an environmental load and must be considered in pipe stress analysis where the climatic condition specifies the possibility of snow or ice formation. Piping projects in various cold geographical locations like Canada, Russia, the USA, Europe, etc where winter temperature falls below a certain limit that causes snow or ice formation must be designed considering the impact of snow loading. Both snow and ice loads are considered as live loads on piping.

Codes and standards stipulate that the system must be designed against snow and ice loading. They provide a lot of guidance for snow loading calculation and application for system design to safeguard them from failure for building structures. But for non-building structures like piping systems, the calculations for snow loading are too limited. In this article, we will try to explore the philosophy of snow loading in piping and pipeline systems and its application in the pipe stress analysis process.

What is Snow and Ice Loading?

Snow and ice loading is a type of sustained loading. The possibility of snow loading will be mentioned in the project environment conditions of the region. Ice and snow loading for piping systems is basically additional downward-acting forces exerted by the accumulated snow and ice. The increase in support load and system stress due to the weight of the accumulated snow and ice must be considered in the structural design.

Snow and ice loading is only significant for outdoor piping installations and is treated similar to other deadweight loads.

In general, snow and ice loading is considered in pipe stress analysis as a uniform load placed over the exterior part of the pipe and fittings. The entire system can fail if the snow loads exceed the allowable of the piping systems. Snow loads are being applied to all pipe elements above ground, and fittings are in a vertical direction downward. The loads depend on the slope angle of each element. The snow loads are given to the elements by using the snow factor.

Though both snow and ice are made up of water there is a slight difference. Snow falls as precipitation of frozen water whereas ice is simply frozen water. In general snow in the piping system is usual for climatic regions. Whereas ice loading generally refers to ice storm deposits over pipes that are decided based on region-specific weather reports.

Snow Load Calculation Philosophy

Snow load calculation philosophy is based on the consideration that the snow accumulated on top of the piping system will take the shape of an equilateral triangle with its base equalling the pipe outside diameter.

The common equation used for calculating the snow loads is as follows:

Ws=(1/2)*Do*So

Here

- Ws=design snow load to be added to other distributed loads acting on pipe, lb/ft

- Do=outside diameter of the pipe (for bare pipe) or insulation (for pipe with insulation), in

- So=Snow Factor that considers the probable snow loading for the region where the piping system is installed, lb/ft2

Ice Loading Calculation Philosophy

Ice loading is also applied in the system as uniform loading and calculated using the following formula as specified in the piping handbook:

Wice=1.36*t*(Do+t)

Here,

- Wice=unit loading on the pipe, lb/ft

- Do=outside diameter of the pipe (for bare pipe) or insulation (for pipe with insulation), in

- t=ice covering thickness, in

Application of Snow Load in Caesar II

Once the uniform load for snow or ice loading is known or calculated, the same is applied in Caesar II and proper load cases are created to account for it. The steps follow are provided below:

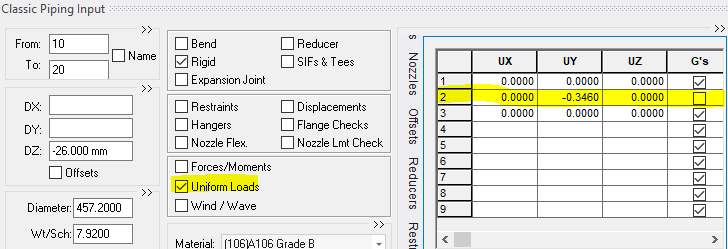

Step 1: Snow load is usually not considered along with wind or seismic load. So, to add snow load in the piping system, simply click on uniform load and add the calculated uniform load value (Note this will vary depending on pipe size) in the input screen as shown below:

In the above example, the calculated snow load per unit length is 0.346 in N/mm for the 18-inch pipe size. The negative sign for the force will act downwards.

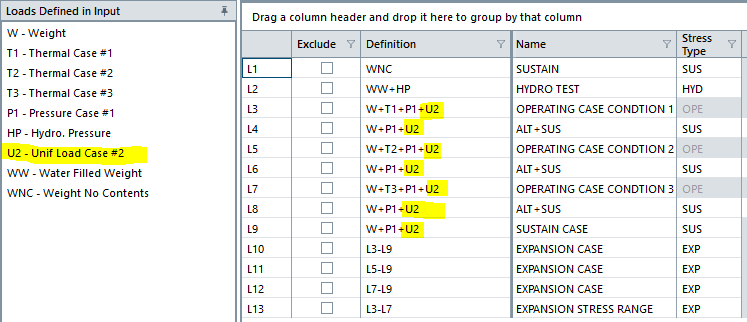

Step 2: Create load cases to account for the above input value as shown in Fig. 2 below:

Step 3: Now you can run the analysis and check the output results. Support loads considering snow loads must be transferred to the Civil team for structural consideration.

Ice loading on the piping system can be applied in a similar fashion if the ice loading is because of the ice storm. However, if the ice generation is because of the cryogenic fluid inside the pipe and moisture condensation, then the same can be considered similar to pipe insulation. Simply, the thickness of ice generation needs to be calculated and that thickness along with ice density can be added as insulation. This means you are roughly considering the pipe is insulated with ice.

Quite complicated with Caesar II, to appply snow load is so easy with Start-prof !

Contact me if you want to know more.

Please recheck the load case. Snow Load should be considered as an Occassional Load Case in areas, where snow falls only in a particular season, similar to Seimic Load or Wind Load cases

Yes, You are right. Please create load cases similar to Seismic/Wind load cases.

I think there is a simple way to consider this in Caesar, i.e, using the wind load (pressure vs elevation) as a downward vertical load. The snow load is equivalent to a pressure load (N/m2, lb/sq inch). Since Caesar know how to apply this to the real diameter (pipe size + insulation), using the shape factor 1 it will result in the same load. Plus you do not need to select the horizontal elements to ally since Caesar “know” how to apply only to the right elements

May I know where the equations are referred from.

Need to check unit point of view on diameter.

The snow loads determined using ANSI A58.1 methods assume horizontal or sloping flat surfaces rather than rounded pipe. Assuming that snow laying on a pipe will take the approximate shape of an equilateral triangle with the base equal to the pipe diameter, the snow load is calculated with the following formula.

Ws=1/2 *D*S

Ws= design snow load acting on the piping, N/m (lb/ft)

D = pipe (and insulation) outside diameter, m (ft)

S = snow load, N/m2 (lb/ft2 )