Submerged pipeline stability is a crucial design element that ensures a pipeline remains in place when subjected to buoyant forces from water or saturated soil. The primary goal is to counteract this upward lift force by adding sufficient weight, keeping the pipeline stable in a cost-effective manner.

𝗠𝗲𝘁𝗵𝗼𝗱𝘀 𝗳𝗼𝗿 𝗕𝘂𝗼𝘆𝗮𝗻𝗰𝘆 𝗖𝗼𝗻𝘁𝗿𝗼𝗹

There are three main strategies to control buoyancy:

Use of Density Anchors

🔹 𝗗𝗲𝗻𝘀𝗶𝘁𝘆 𝗔𝗻𝗰𝗵𝗼𝗿𝘀 (𝗖𝗼𝗻𝗰𝗿𝗲𝘁𝗲 𝗪𝗲𝗶𝗴𝗵𝘁𝘀) This is the most common method and involves adding concrete weights to the pipeline.

- Swamp Weights: Inverted “U”-shaped weights placed over the pipe in wet areas like swamps and bogs. They are economical and easy to install.

- River Weights: Two-piece weights that are bolted directly onto the pipe. They are used for river crossings where the pipe is assembled with weights before being moved into place.

Example of Rigid Weights

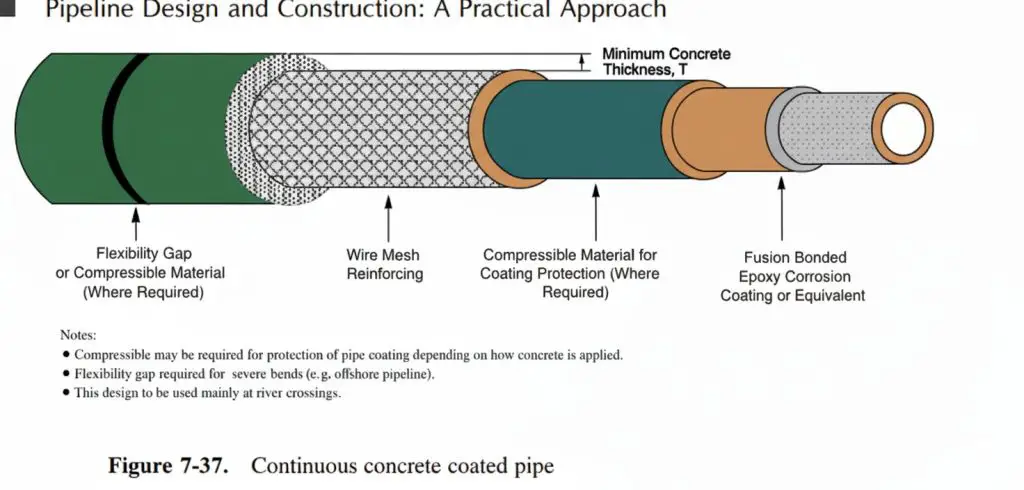

3. Continuous Concrete Coating: A reinforced concrete jacket that completely surrounds the pipe. It offers excellent weight and mechanical protection, making it ideal for major river crossings or rocky environments.

Use of Backfills

🔹 𝗕𝗮𝗰𝗸𝗳𝗶𝗹𝗹 This method uses the mass of the soil placed over the pipe to hold it down. It’s a viable option if the trench can be kept dry during construction, but the area may become saturated later.

Use of Mechanical Anchors

🔹 𝗠𝗲𝗰𝗵𝗮𝗻𝗶𝗰𝗮𝗹 𝗔𝗻𝗰𝗵𝗼𝗿𝘀 These devices, often screw-like anchors, are driven into the soil and attached to the pipeline with straps. They use the shear strength of the soil to provide a holding force and are useful in swamplands where heavy concrete is impractical.

𝗔𝗹𝘁𝗲𝗿𝗻𝗮𝘁𝗶𝘃𝗲 𝗪𝗲𝗶𝗴𝗵𝘁𝗶𝗻𝗴 𝗠𝗲𝘁𝗵𝗼𝗱𝘀

Other options for adding weight include:

- 🔹 Increased Pipe Wall Thickness: This is generally only economical for small-diameter pipes.

- 🔹 Geotextile Bags (PipeSaks®): These are fabric bags filled with heavy material like gravel and draped over the pipe like a saddle, offering a flexible weighting solution.

Final selection of the type and extent of buoyancy control measures should be made on a site-specific basis, taking the following into consideration: type of terrain, type of soil, ditch conditions (dry or wet), construction season, cost (economics), availability of materials, access to site, ease of handling during transport and construction, and limitations of equipment.

References:

- Handbook of Pipeline Engineering

- PIPELINE DESIGN & CONSTRUCTION: A Practical Approach