The ASME U Stamp is an indication of quality for Pressure Vessels. It ensures that the design, fabrication, inspection, and testing of pressure vessels conform to ASME’s guidelines. ASME U stamp is provided on the body or the nameplates of the pressure vessels as a certification to meet ASME requirements. Globally, more than 100 countries use the ASME BPVC code for the pressure vessel design and U-stamped vessels follow the requirements of ASME Sec VIII Div 1. For the maximum protection of life and property, ASME provides rigorous rules for Pressure vessels. In many countries, the government made it compulsory to purchase ASME U-stamped vessels.

Advantages of ASME U Stamp

The main advantages of the ASME U Stamp are listed below:

- In many countries, for pressure vessel installations in human occupancy, the ASME U stamp is a must.

- ASME U stamp is a mandatory requirement of most Insurance companies.

- ASME U stamp is accepted under all jurisdictions.

- Sometimes for approvals by local regulating agencies, the ASME U stamp is a requirement.

ASME U Stamp requirements

The pressure vessels under ASME U stamp requirements are specifically inspected by a third-party authorized inspector. The inspector must review and approve the calculations as well as witness the ASME hydro test. Such inspectors are commissioned by the National Board of Boiler and Pressure Vessel Inspectors. A complete data report is furnished in form U-1 containing the signature of the authorized inspector. The manufacturers of such pressure vessels need to be registered with the National Board for the production of ASME U-stamped pressure vessels. Also, they need to maintain a permanent data record of all pressure vessels.

The manufacturers wishing to qualify as ASME certified need to go through the following stringent safety procedures:

- Preparation Stage: The manufacturer must fulfill all requirements, and fill all checklists.

- Application stage: Submit the complete application along with a signed Accreditation and Certification Agreement Form and the required fee.

- Assessment Stage: ASME review team will examine the design, manufacturing, inspection, and quality system of the applicant. Once the assessment is complete, the team will submit an evaluation report to the higher authority.

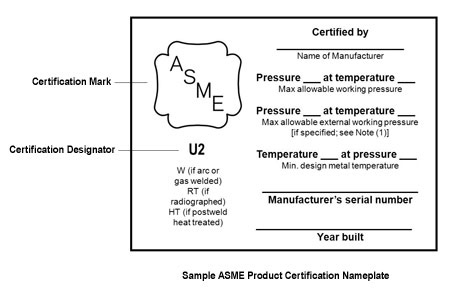

- Certification Stage: Once the applicant successfully demonstrates the implementation of quality programs in every stage of vessel manufacturing, he is entitled to the ASME certification. Upon receipt of the accreditation, the manufacturer can stamp the ASME mark on the vessel’s surface or Nameplates. Fig. 1 below shows a sample ASME certification stamp template.

For more details about the marking methods, nameplate details and data reports kindly refer to UG-118 to UG-120 from the latest edition of ASME BPVC Sec VIII Div. 1.

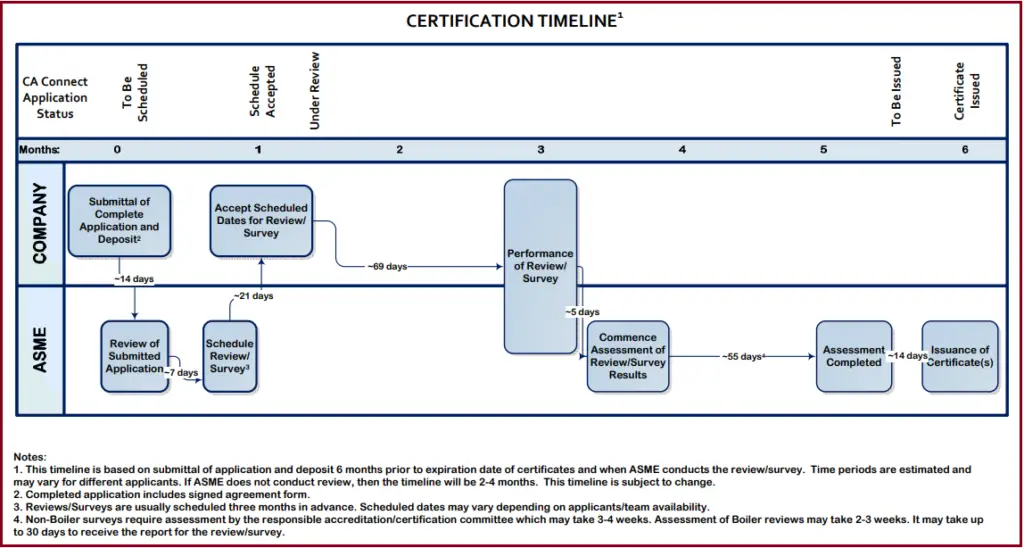

There is a timeline involved for each stage mentioned above. The following flow chart (Fig. 2) by the ASME provides a guideline for the same.

Is ASME U stamping a mandatory requirement?

No, the U stamp is not a mandatory requirement. The requirement is decided by the client company. As pressure vessels operate in a wide variety of processes and environments, It is crucial to design and fabricate vessels of the highest possible standard and quality. ASME U stamp satisfies that requirement. Failure to obtain an ASME vessel can sometimes put the business at risk.

When do Pressure Vessels need Certification or U-Stamping?

Any vessel carrying pressure in excess of 15 PSI falls under the ASME Code and should be stamped or certified by the ASME. However, there are other factors as well.

How to find ASME Certified Companies in a country?

To find the list of ASME-certified companies kindly visit the following site: https://caconnect.asme.org/directory/?_ga=2.17247673.1842524440.1614010223-219895220.1614010223. Provide the country and certificate type and then click on the search button. It will list all the companies that have active ASME certification during that time.

Online Course on Pressure Vessels

If you wish to learn more about Pressure Vessels, their design, fabrication, installation, etc in depth, then the following online courses will surely help you:

Thanks anup for sharing your knowledge.

Simple and Clear information on the Code Stamping. Thanks and lot

hi sir

i would like to asked about ASME AND NBIC U stamp and r stamp

Fees.

and required codes bundule rates

Best regards

Hello

I am working as AI and Can help you for shop certification .

You can contact me on 8484848029

Hi Anup, thanks for the valuable information on the U-stamp. Let say, the vessel or basket strainer is fabricated from the pipe. Is it required the U-stamp as well?

Hi Anup, good post for knowledge seekers. I have a question, I am planning to import 500L Bio rectors (fermenters) for our Process lab in the USA. Their Operating pressure is 30PSI and design pressure is 42PSI. DO I need to have U stamp and what are the requirments for ispedction? Can I design them per ASME and not have U stamp and still operate in my Lab?