Tee or Tee connection in piping engineering is a very important pipe fitting and is frequently used to combine or divide a flow. Two types of Tee are available, Equal Tee and Reducing Tee. However, in pigged pipelines, one special type of tee connection is widely used which is known as Barred Tee or Pigged Tee. In this article, we will try to study a few points about Barred Tee and Tee Connections.

Tee vs Barred Tee

Tee is a type of pipe fitting that allows fluid to flow on its main pipe and branch out. The branch can be designed equally the same size as the main pipe (known as Equal Tee), or smaller size than the main pipe (known as Reducing Tee).

Barred Tee is a special type of Tee that is based on a normal tee (can be either an equal tee or a reducing tee) that at a later stage, will be added with bar plates inside the branch outlet (From inside it looks like a steel cage) to restrict the PIG (pipeline PIGGING) from flowing from the header pipe into the branch pipes.

Design Codes and Standards for Tee and Barred Tee

- The international standard dimension of the tee will be covered under ASME B16.9 or MSS-SP 75 (for DN16 and above). Click here to know more about Tee Connections.

- There is no international standard dimension for the barred tee. It is custom-made using the ASME B16.9/ MSS-SP 75 tee as a base. However, many develop their barred tee based on Shell DEP 31.40.10.13-Gen or ISO 15590-2 standard.

- This design can be a guideline to assess Vendor’s design.

Design Considerations for Barred Tee

The barred tee will be used when there is a requirement for pigging. Thus, many of its applications can be found in the pipeline or in the subsea field.

The bar plates that are welded internally at the branch are to avoid the pig from changing direction or getting stuck at the branch outlet.

The design of the bar plates must be in sufficient quantity, thickness, and adequately spaced to ensure the smoothness for the pig to run through the main pipe, and at the same time not affect the flow that was meant to flow through the branch. Normal practice is to ensure that the opening in the branch pipeline after guided bars is not more than 40% of the main pipeline area.

The size of the bars in the branch connection has to be small enough not to restrict the flow but large enough to sustain the pressure of the flow.

To ensure smoothness, the bar plates have to be a grind to suit the branch curvature. Any sharp edges spatter, and burs are required to be removed. This smoothness of the pigging process is important to protect the sensor of pig from damage.

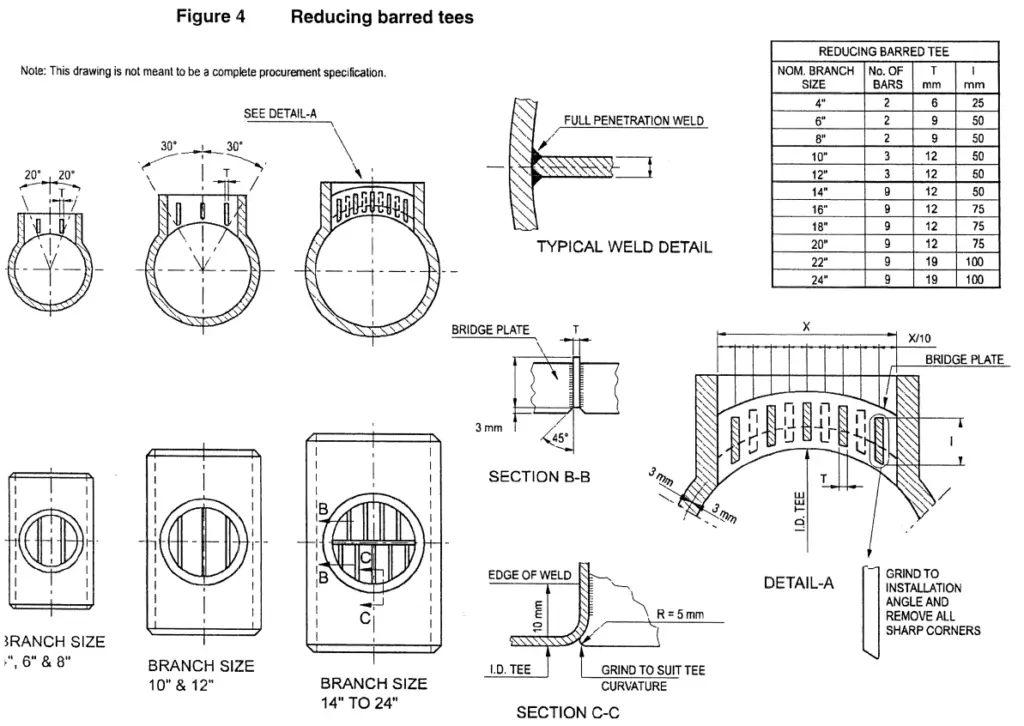

Refer to Shell DEP 31.40.10.13-Gen Figure 4 above; the quantity of the bar plates start with two (2) pieces and increase as the ID of the branch increase.

The bar plates ideally will be equally spaced.

For a larger tee (size 14 inches and above), there will be a bridge plate in the middle to support the bar stiffness when getting hit by the pig.

The material of the bar plates is commonly used the same as the tee material for weldability.

Standard practice is to avoid welding guide bars directly on the high-stress concentrated areas of the extrusion neck. Bar ends must be machined to fit the branch.

Weld Repairs on Parent metal are prohibited.

Difference Between Tee and Barred Tee

So from the above discussion, we can summarize the following differences:

| Parameter | Tee | Barred Tee |

| Definition | Standard Pipe Fitting | A special type of piping component |

| Manufacturing | Generally by Extrusion or forging | Mostly Fabricated |

| Use | Used in both piping and pipeline engineering | used in pipeline engineering near the pig launcher/receiver |

| Design Code / Standard | ASME B16.9/MSS SP 75 | Shell DEP 31.40.10.13-Gen or ISO 15590-2 |

| Production Quantity | Large scale in bulk | Select small quantities (custom-made) |

| Cost | Cheaper | Costlier than normal Tee |

Few more references for you

Piping Design and Layout

Piping Materials

Piping Stress Analysis

Piping Interface

What is Bridge plate in Barred tee

What shall be the SIF in Caesar II for Barred tee?

Will it be same as normal tee or do we need to consider some additional rigidity due to the bar plates?

Guys, wish all the best! It is nice to have such sources of information for all beginners.

Hi.

Can anybody tell me in which standard, the following rules is defined?

“Normal practice is to ensure that the opening in the branch pipeline after guided bars is not more than 40% of the main pipeline area.”

Regards,