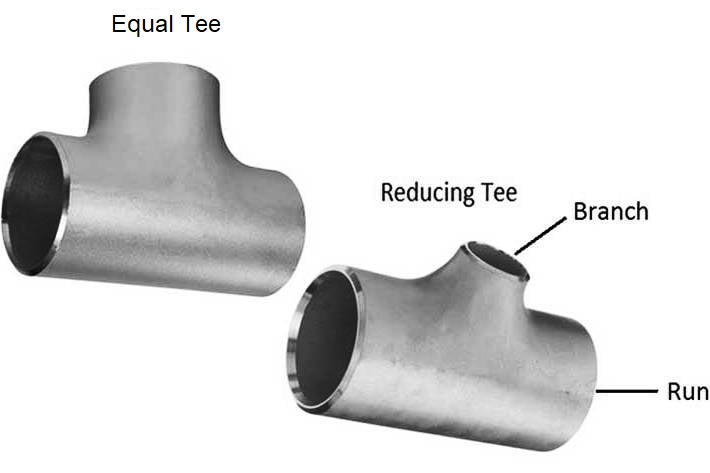

Piping Tees are used either for dividing the main fluid flow into two streams or for combining flow from two streams. The term Tee for these types of pipe fittings most probably comes from the resemblance of the English letter Tee.

The main run pipe has often termed a Header and the other as a branch. The branch size may be smaller or equal to the run pipe size but it cannot be larger. Tees having branch size equal to run size are called equal tees & others as unequal tees or reducing tees.

Tees are normally designed based on ASME B16.9 or ASME B16.11. Tee is always normal or perpendicular to the pipe axis and is normally produced by forging.

Types of Piping Tee Connections

Piping tee connections are classified according to the branch size and end connection.

Based on the branch size, there are two types of piping tee connections. They are:

- Equal Tee, and

- Reducing Tee

Equal Piping Tee:

When the branch size is equal to the run pipe it is called Equal Tee pipe fitting.

Reducing Piping Tee:

In the case of reducing tee, the branch size is smaller than the run pipe size. there is a limitation to the branch size. It can not be sufficiently smaller. For example, Reducing Tee from 16″ pipe is available up to 6″ branch size. 16″ X 4″ piping tee is not manufactured. Usually reducing piping tee connections are manufactured till a branch pipe size of one size lower than 1/2 the parent pipe size. This rule is valid till 28″.

Based on the pipe end connections, tees are classified as follows:

- Socket Welded Tees

- Screwed-End Tees

- Butt Welding Tees

- Flanged Tees

Socket Welded Tees

- These are usually forged and used up to 2” run size on services where socket welded connections are permitted.

- The applicable dimensional standard is ASME B16.11 and material standards including ratings are the same as those for socket-welded elbows.

- Normal industry practice is to use socket welded tees up to 1 1/2” run size.

Screwed-end Tees

Their use including rating, dimensional, and material standards are the same as applicable to screwed elbows.

Butt welding Tees

- The dimensional standard applicable for equal and unequal tees is ANSI B16.9. These are available from 1/2” through 48”.

- Unequal butt welding tees are available having branches up to one size lower than half run size e.g. If the run size is 8”, unequal tees are available in sizes 8” × 6”, 8” × 5”, 8” × 4” & 8” × 3 1/2”.

- Applicable Pressure temperature rating and material standards are the same as those for butt-welding elbows.

- Butt welding tees are usually used for size 2” and above and in smaller sizes for services where the use of socket weld joints is prohibited.

Flanged Tees

Their use including pressure rating, and dimensional & material standards are the same as applicable to flanged elbows.

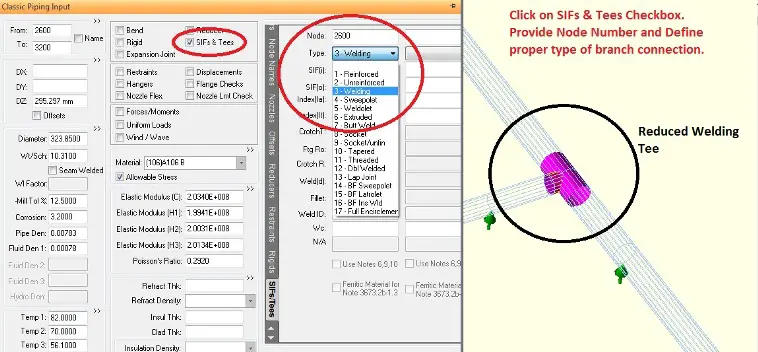

In normal large-bore pressure piping most often Butt-welded Tee connections are used. The ASME B31.3 (Appendix D) is used to provide a formula for calculating the SIF value at tee connections which Caesar automatically calculates when Tee is defined. From the ASME B31.3-2020 onwards, Appendix D is deleted from the code. Now Stress Intensification and Flexibility factors are to be calculated using the ASME B31J code. The Tee connections are normally defined in Caesar as shown in the attached figure.

For pipeline systems, a special type of tee is used, known as Barred Tee.

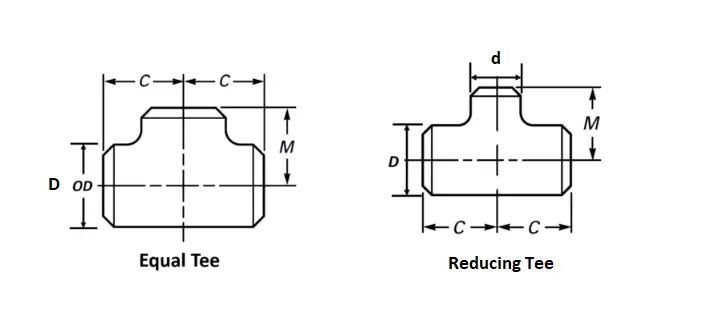

Piping Tee Dimensions

Equal Tee Dimension Chart

Refer to the following table (Table-1) for the Tee dimension chart for equal pipe tee as per ASME B16.9

| NPS (Inches) | Outside Diameter at Bevel (D, mm) | Center to End (C, mm) | Center to Center (M, mm) |

|---|---|---|---|

| 1/2 | 21.3 | 25 | 25 |

| 3/4 | 26.7 | 29 | 29 |

| 1 | 33.4 | 38 | 38 |

| 1 1/4 | 42.2 | 48 | 48 |

| 1 1/2 | 48.3 | 57 | 57 |

| 2 | 60.3 | 64 | 64 |

| 2 1/2 | 73.0 | 76 | 76 |

| 3 | 88.9 | 86 | 86 |

| 3 1/2 | 101.6 | 95 | 95 |

| 4 | 114.3 | 105 | 105 |

| 5 | 141.3 | 124 | 124 |

| 6 | 168.3 | 143 | 143 |

| 8 | 219.1 | 178 | 178 |

| 10 | 273.0 | 216 | 216 |

| 12 | 323.8 | 254 | 254 |

| 14 | 355.6 | 279 | 279 |

| 16 | 406.4 | 305 | 305 |

| 18 | 457.0 | 343 | 343 |

| 20 | 508.0 | 381 | 381 |

| 24 | 610.0 | 432 | 432 |

| 26 | 660 | 495 | 495 |

| 28 | 711 | 521 | 521 |

| 30 | 762 | 559 | 559 |

| 32 | 813 | 597 | 597 |

| 34 | 864 | 635 | 635 |

| 36 | 914 | 673 | 673 |

| 38 | 965 | 711 | 711 |

| 40 | 1016 | 749 | 749 |

| 42 | 1067 | 762 | 711 |

| 44 | 1118 | 813 | 762 |

| 46 | 1168 | 851 | 800 |

| 48 | 1219 | 889 | 838 |

Refer to Fig. 3 below to understand the notation used in Table 1 and Table 2.

Reducing Piping Tee Dimensions Chart

Refer to Table-2 which provides the reducing Pipe Tee dimensions.

| NPS (Inches) | Large End Outside Diameter (D, mm) | Small End Outside Diameter (d, mm) | Center to End (C, mm) | Center to Center (M, mm) |

|---|---|---|---|---|

| 1/2 x 3/8 | 21.3 | 17.1 | 25 | 25 |

| 1/2 x 1/4 | 21.3 | 13.7 | 25 | 25 |

| 3/4 x 1/2 | 26.7 | 21.3 | 29 | 29 |

| 3/4 x 3/8 | 26.7 | 17.1 | 29 | 29 |

| 1 x 1/2 | 33.4 | 21.3 | 38 | 38 |

| 1 x 3/4 | 33.4 | 26.7 | 38 | 38 |

| 1 1/4 x 1/2 | 42.2 | 21.3 | 48 | 48 |

| 1 1/4 x 3/4 | 42.2 | 26.7 | 48 | 48 |

| 1 1/4 x 1 | 42.2 | 33.4 | 48 | 48 |

| 1 1/2 x 1/2 | 48.3 | 21.3 | 57 | 57 |

| 1 1/2 x 3/4 | 48.3 | 26.7 | 57 | 57 |

| 1 1/2 x 1 | 48.3 | 33.4 | 57 | 57 |

| 1 1/2 x 1 1/4 | 48.3 | 42.2 | 57 | 57 |

| 2 x 3/4 | 60.3 | 26.7 | 64 | 44 |

| 2 x 1 | 60.3 | 33.4 | 64 | 51 |

| 2 x 1 1/4 | 60.3 | 42.2 | 64 | 57 |

| 2 x 1 1/2 | 60.3 | 48.3 | 64 | 60 |

| 2 1/2 x 1 | 73.0 | 33.4 | 76 | 57 |

| 2 1/2 x 1 1/4 | 73.0 | 42.2 | 76 | 64 |

| 2 1/2 x 1 1/2 | 73.0 | 48.3 | 76 | 67 |

| 2 1/2 x 2 | 73.0 | 60.3 | 76 | 70 |

Few more related articles for you.

Difference between Tee and Barred Tee

Smart Tee Model considerations in START-PROF

Inspection & Test, Marking & Colour Coding and Packing Requirements for Pipes & Fittings

Technical requirements for Pipes & Fittings for preparation of Purchase Requisition

Piping Elbows vs Bends: A useful literature for piping engineers

Hi,

Can you please explain how we will model socket weld tee and elbow and what SIF we will use?

thanks

Hi,

highly appreciated if you can explain comparing between barred tee & scrapper tee.

thank you

Hi,you give very good explaintion about tee connection and you also classified a connection,Nice article!!

Hi Anup! This blog is really working for me. And I am really inspired by your passion to share knowledge. I am working on CEASAR-II 2016 since last one year but I need some help to clear some functional doubts. So can you share your no. here or ping me on 07228051832.

It been 2 years since my visit in this blog and still, your articles remind me and take me back to school, thank you.

Greetings,

what are the advantages/benefits of using the equal tee in fire water hydrants.