Why Software may show Zero Anchor Loads?

While stress analysis and supporting considerations it is always a better engineering practice to provide line stops or axial stops or pipe anchors at the neutral point of the straight portion of the piping. It is believed that at the neutral point, thermal movement is zero and frictional resistance equalizes from both sides of the piping system. In such a scenario, the frictional forces cancel out as forces are positive on one side and negative on the other. Also as there is no thermal movement, there will be zero axial loads due to the temperature effect. So, the software will show zero anchor loads in such locations.

Example of Zero Anchor Loads

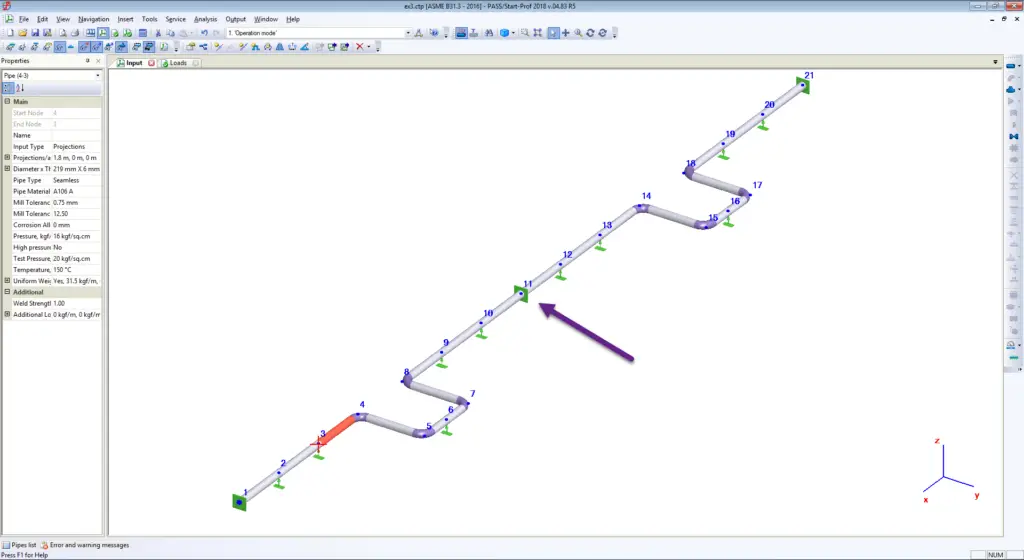

For example, In the following symmetric system with two U-shape loops, as shown in Fig. 1, The leg length on both sides of the intermediate anchor is equal. Thus the intermediate anchor node 11 becomes a neutral point.

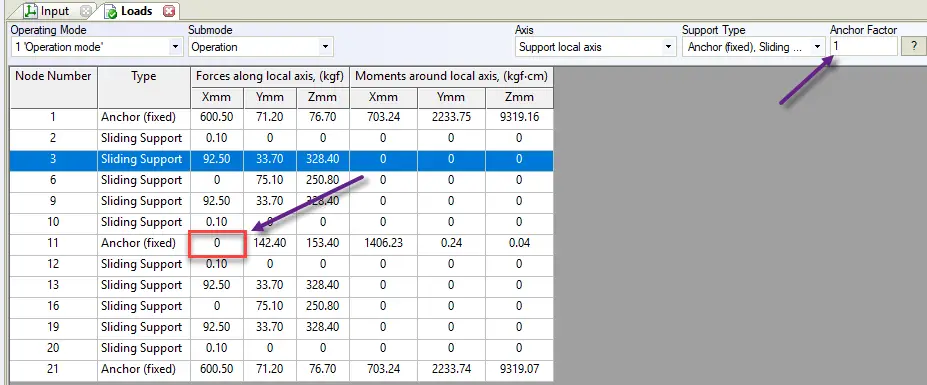

As can be seen in Fig. 2, The load along the pipe in an intermediate anchor (node 11) will be zero.

In reality, the piping heating up can be uneven, the friction forces can be different on the left and right parts of the piping, piping design can’t be ideal. Therefore, the real load on the anchor will not be zero.

How to Avoid Zero Anchor Loads?

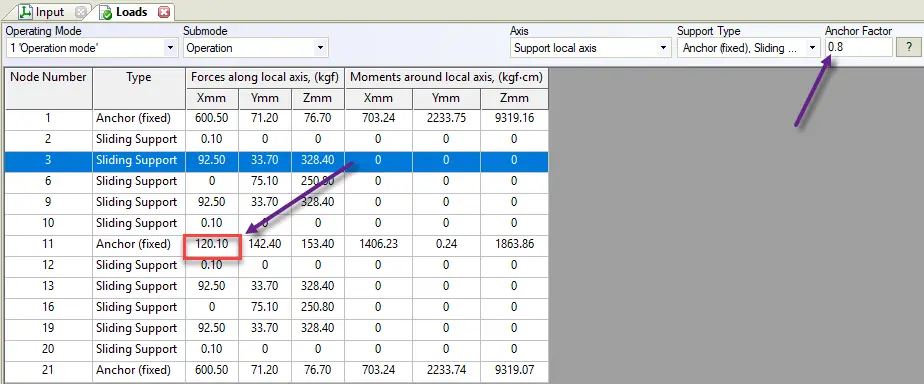

To avoid such a situation the Anchor Factor “k” is used in piping stress engineering practice. The following method can be manually used in any pipe stress analysis software. In PASS/START-PROF piping stress analysis software this is a built-in function.

- If loads from pipes to the left and right of the support (N1 and N2) are in the same direction, they are combined as N1+N2

- If loads N1 and N2 are in different directions, the lower values are multiplied by k and then combined as N1+N2*k (|N2|<|N1|)

- If the support is on an end node, factor k is not used

Factor k is applied only for loads in the horizontal plane: axial force, lateral force, and horizontal moment.

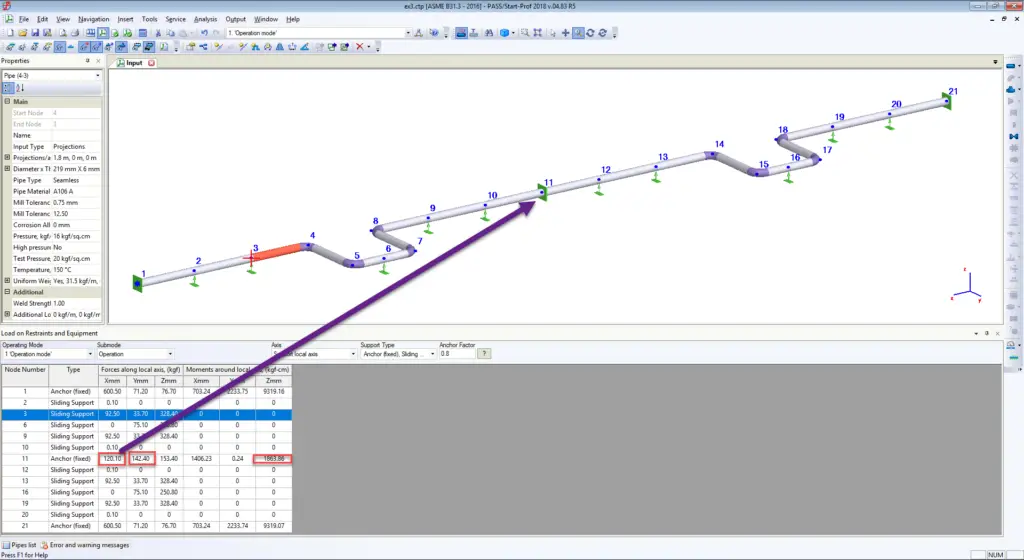

The common value, that is recommended by some piping stress analysis codes is k=0.8. If we use a 0.8 value the result will be as shown in Fig. 3. and Fig. 4.

The following training video shows how to create this model. It takes 2 minutes

Few more Resources for you..

Stress Analysis using Start-Prof

Stress Analysis using Caesar II

Piping Stress Analysis Basics

Piping Design and Layout

Piping Materials

Is there anything specified in en 13480 regarding Factor k? If so, in which chapter would i find it?

No information in EN. Factor k=0.8 is specified in codes SNiP 2.05.06-85 and SP 36.13330.2012. Also k=0.8 is offered in many Russian piping design and stress analysis handbooks. It is common design practice since 1950

Sir where we can find job for fresher student or less experince like 1 Or 2 year experince people

Why you want to avoid zero anchor load? What is the harm in having zero load at anchor support if the condition is such?

Some companies require it, because they want to give some loads to structural engineers. If the load is zero, then how to design this support size, foundation size for it, etc?