Link-Seals are mechanical seals for creating air, water, or a gas-tight seal between a pipe and a core hole. They are available in a belt form with a series of interconnecting rubber links, pressure plates, and bolts. For sealing a pipe or cable with a casing sleeve/ pipe sleeve, duct, or wall, link-seal systems are proven to be very useful and hence find wide applications in various industries. They are believed to be one of the premier methods for permanent sealing of the annular space between the pipes & any size of walls, floors, or ceiling penetrations. In actual practice, link seals can be used to quickly, easily, and permanently seal any kind of cylindrical object with its penetration barriers. In the oil and gas industries, Link-Seal Modular Seal designs have the capability to seal pipe penetrations ranging in size from 10 mm to 3.6m in diameter.

Advantages of Link Seal Systems

Link seal systems as a permanent sealing system provide several benefits as mentioned below:

- Positive hydrostatic sealing.

- Resistant to temperature (-500C to 2040C), and chemical attack (corrosion).

- Long sealing life.

- Easy to adjust and re-fit.

- Possible to install during the pipe operation, no plant shutdown is required.

- Available in fire-rated form.

- Can absorb slight pipe movements.

- Economical.

- Once installed, almost maintenance-free.

- Link seals are available in various sizes to suit any requirement.

- Absorbs shock, sound, and vibration

Applications of Link-Seal

Because of the above-mentioned advantages, Link seal systems are widely in almost all types of industries. Some of the applications of link seals are mentioned below:

- Manhole Pipe Entry Seals

- Cased Road Crossings

- Thermal Storage Systems

- Dual Containment Seals

- Fire Protection Wall Penetrations

- Waste Treatment Plants

- Cased Railroad Crossings

- Electrical Isolation of Pipes

- Precast Concrete Vault Seals

- Insulated Pipe Seals

- Noise Dampening

- Flexible Sign & Pole Supports

- Marine Applications

- Electrical Isolation of Pipe Supports

- Mining Industries

- Pulp & Paper Industries

- Decorative Fountains

- High-Pressure Tank Guards

- Underground Steel Tanks

- Electrical Contractors

- Valve and Flange Pits

- Pool Contractors

- Waste Water Treatment

- Telecommunications

- Refrigeration Buildings

- Guard Post Assemblies

- Power Generation Dams

- Offshore Oil Rigs

- Coal Preparation Plants

- Tunneling Operations

- Precast Concrete Manufacturers

- Perimeter Berm Installations Around Tank Farms

- Flow Restrictors in Sewer Maintenance

- Fluid Overflow Devices

- Noise and Sway Dampener

- Through Deck Fire Breaks

- Bridge Construction

- Septic Tank Installations

How Does a Link Seal Work?

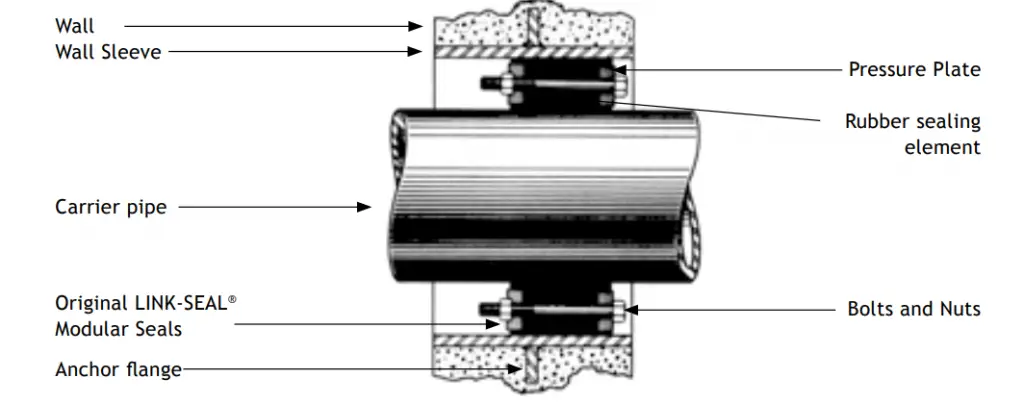

While installing the link-seal belt is positioned between the pipe and the annular wall. Then following the proper tightening sequence the link-seal is tightened. Once installed the link-seals provide a pressure-tight and secure sealing by the radial expansion of the rubbers in the annual spaces. Refer to the following image that shows the sectional drawing of a wall penetration sealed with a link seal.

Installation of Link-Seal System

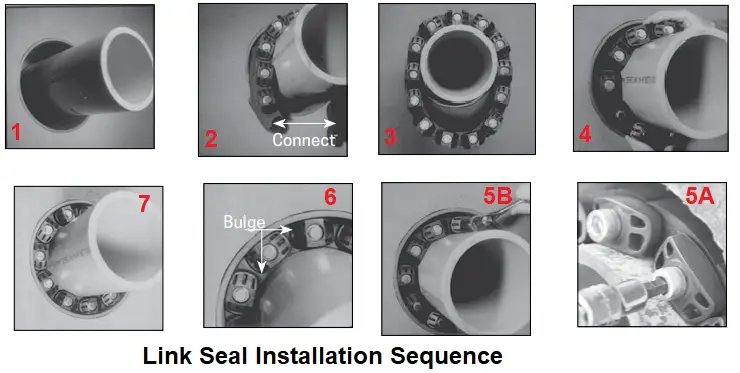

The installation sequence of a link-seal system (Fig. 2) is provided below:

- Centre the pipe in the casing or wall opening. The pipe should be supported adequately on both ends.

- Loosen the rear pressure plate of the link-seal belt with a nut such that the links can move freely. Connect both ends of the belt around the pipe.

- Ensure that all bolt heads of the link-seal system are facing the installer. Extra slack or sag is normal. Hence, Do not remove links if extra slack exists.

- Slide the belt assembly into the annular space.

- Using a hand socket Allen head, hand socket, or off-set wrench, start at 12 o’clock. Do not tighten any bolt more than 4 turns at a time. Continue in a clockwise manner until links have been uniformly compressed.

- Make 2 or 3 more passes at 4 turns per bolt, tightening all bolts clockwise until all sealing elements “bulge” around all pressure plates

- Once all sealing elements bulge out, the link seal installation is complete and ready for use.

Sizing of Link Seal

Proper sizing of link seals is very important. It requires calculating some parameters. The link seal sizing sequence is provided below:

Calculating Annular Space: The annular space is half the difference between the actual pipe O.D. and the actual wall I.D. opening diameter. The following equation can be used:

Annular Space=(ID of wall opening or sleeve-Actual Pipe OD)/2

Calculating the number of links required: To find the number of links first we have to calculate the bolt circle diameter using the following formula:

Bolt Circle Diameter=(Wall/Sleeve opening ID+Pipe Actual OD)/2

Next, the number of links for each seal can be calculated as follows:

Number of links per seal=(Bolt circle diameter X 3.14)/Arc Length

Arc length or Chord length will be available in the manufacturer catalogs.

Once the above parameters are calculated, the required link-seal can easily be selected from the manufacturer’s catalog.

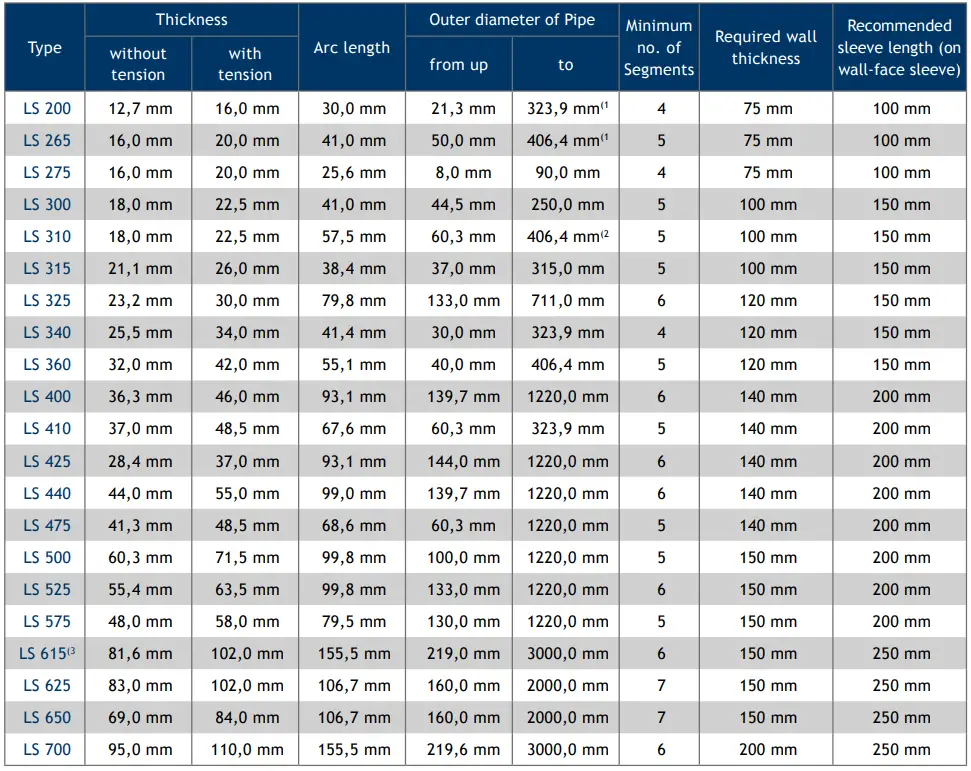

Link Seal Sizing Chart

A typical link seal size chart is provided in Fig. 3 below as a sample. The manufacturer catalog must be followed during actual link-seal sizing and selection.

Link Seal Catalog

Some of the link-seal manufacturer catalogs are provided below for more learning and reference.