In the vast world of piping and plumbing systems, numerous components play crucial roles in ensuring the efficient and reliable functioning of the infrastructure. One such unsung hero that often goes unnoticed is the “Puddle Flange.” Though lesser known, this unassuming device plays a vital role in preventing leakage and safeguarding against potential structural damage. In this article, we will explore what a puddle flange is, how it works, its applications, and why it deserves more recognition in the piping and plumbing industry.

What is a Puddle Flange?

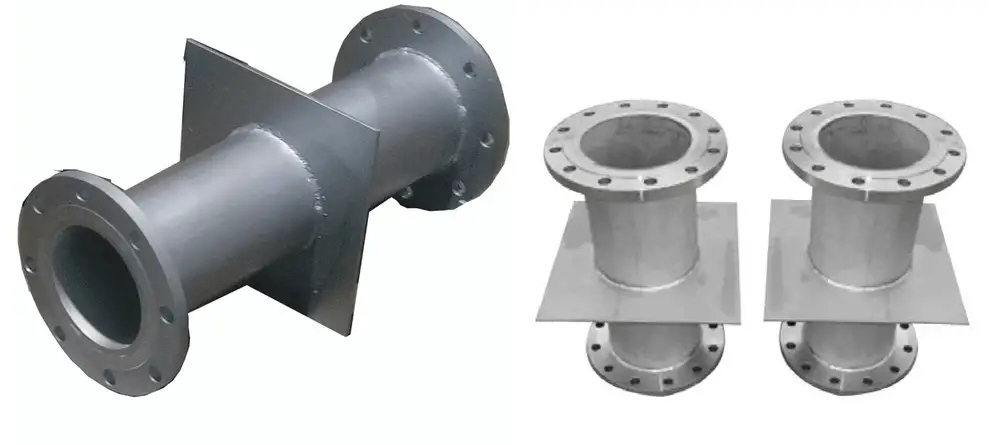

A puddle flange, also known as a floor flange or a plinth flange, is a specialized piping and plumbing fitting designed to prevent water (or other fluid) penetration through floor or wall openings where pipes pass through. It is typically a disc-shaped or ring-like component made from durable materials such as carbon steel, PVC, stainless steel, or rubber. Puddle flanges are available in various sizes and designs to accommodate different pipe diameters and applications.

Puddle flanges are specialized fittings used to create a watertight seal around pipes that penetrate walls, floors, or any other barriers. Their primary function is to prevent the ingress of water, fluids, or other contaminants into sensitive areas. In oil and gas applications, where exposure to various liquids and environmental conditions is common, the importance of a reliable seal cannot be overstated.

How Does a Puddle Flange Work?

The primary function of a puddle flange is to create a fluid barrier around the point where a pipe passes through a floor or wall, such as in flange pits, bathrooms, kitchens, basements, or external areas. When a pipe penetrates through a concrete slab or wall, there is a potential risk of leakage. Without proper sealing, water can damage the structural integrity of the building, leading to mold growth, rot, and even compromising the stability of the foundation.

When installing a puddle flange, it is positioned around the pipe before pouring the concrete or mortar. The flange is then embedded in the concrete, creating a watertight seal that prevents liquid from seeping through the joint between the pipe and the surrounding surface. By redirecting any liquid that may come in contact with the pipe, the puddle flange ensures that moisture stays away from the structure, mitigating potential damage over time. Fig. 1 below shows a typical example of puddle flanges

Applications of Puddle Flanges in the Plumbing Industry

In the plumbing industry, the use of puddle flanges is found in

Wet Areas:

Puddle flanges are commonly used in bathrooms, shower areas, and kitchens where plumbing pipes pass through the floors or walls. They provide a waterproof barrier, ensuring that water does not seep into the building structure and cause water damage.

Basements:

In basements or underground structures, where the risk of water infiltration is higher, puddle flanges play a critical role in keeping the area dry and protecting the building from moisture-related problems.

External Plumbing:

For plumbing installations that pass through external walls, puddle flanges are essential in preventing rainwater from entering the building envelope.

Piping in Concrete Slabs:

Puddle flanges are widely used when laying pipes in concrete slabs, such as in commercial buildings, industrial facilities, and residential constructions.

Advantages of Puddle Flanges

Installation of puddle flanges provides the following advantages:

- Water Sealing: The primary advantage of puddle flanges is their exceptional ability to prevent water leakage, thus maintaining the integrity of the structure and preventing costly repairs.

- Easy Installation: Puddle flanges are relatively easy to install during the construction or renovation process, requiring minimal effort and time.

- Longevity: Made from durable materials, puddle flanges have a long lifespan, offering reliable protection against water infiltration for many years.

- Reduced Maintenance: By keeping water at bay, puddle flanges reduce the need for constant maintenance and repair due to water-induced damages.

Application of Puddle Flanges in the Oil and Gas Industry

In the oil and gas industry, puddle flanges play a crucial role in providing a secure and watertight seal around pipe penetrations in various applications. These specialized flanges are specifically designed to address the unique challenges and requirements of the industry. Here are some key uses of puddle flanges in the oil and gas sector:

Subsea Pipelines:

Puddle flanges are commonly used in subsea pipeline installations. When pipelines are laid on the seabed, they often pass through concrete or steel structures. Puddle flanges are utilized at these penetration points to prevent seawater from entering the structures and causing corrosion or damage to sensitive equipment and infrastructure.

Offshore Platforms:

In offshore oil and gas production platforms, puddle flanges are employed to create watertight seals around penetrations through the platform decks and walls. These flanges ensure that the seawater does not infiltrate the platform’s interior, protecting critical equipment, machinery, and personnel working in these facilities.

Floating Production Systems:

Floating production platforms and floating storage units have various piping systems and risers that need to pass through the vessel’s hull. Puddle flanges are used at these penetration points to maintain the integrity of the hull and prevent water from entering the vessel’s interior.

Refineries and Petrochemical Plants:

Puddle flanges are utilized in refineries and petrochemical plants to seal pipe penetrations through concrete foundations or containment structures. They protect against the potential leakage of hazardous chemicals or hydrocarbons that could lead to environmental hazards or safety risks.

Tank Farms and Storage Terminals:

In facilities where crude oil, petroleum products, or liquefied natural gas (LNG) are stored in tanks, puddle flanges are employed to seal pipe penetrations through the tank walls and bund walls. This prevents any spills or leaks from contaminating the surrounding environment or causing accidents.

Onshore Pipelines:

Puddle flanges are also used in onshore pipelines, especially when the pipelines pass through concrete containment structures, pump stations, or valve pits. They help maintain the structural integrity of these facilities and protect against soil contamination in environmentally sensitive areas.

Pipeline Crossings:

In instances where pipelines cross water bodies or sensitive ecological regions, puddle flanges provide a reliable barrier against water infiltration, safeguarding the pipeline and minimizing environmental impact.

Advantages of Puddle Flanges in the Oil and Gas Industry:

- Corrosion Prevention: By preventing seawater or other corrosive substances from entering structures, puddle flanges help extend the service life of the equipment and reduce maintenance costs.

- Environmental Protection: Puddle flanges play a vital role in containing potential leaks or spills, safeguarding the environment, and preventing ecological disasters.

- Safety Assurance: Ensuring watertight seals around critical infrastructure enhances safety for workers and the surrounding environment.

- Long-Term Reliability: Puddle flanges are made from durable materials that can withstand harsh offshore and onshore conditions, providing long-lasting protection.

Types of Puddle Flanges

Let’s explore the various types of puddle flanges and their unique characteristics:

Standard Puddle Flanges

Description: The standard puddle flange is the foundational element in the puddle flange lineup. Designed to create a robust, impermeable seal, it effectively protects pipes and surrounding structural components from water ingress.

Materials: These flanges are crafted from durable materials that offer resistance to environmental challenges, ensuring longevity and reliability in various applications.

Tapped Puddle Flanges

Description: Tapped puddle flanges are notable for their adaptability. Featuring taps or openings, they facilitate multiple pipe connections and provide a flexible solution for construction scenarios that require customization.

Applications: Commonly used in situations where a tailored approach to pipe connections is essential, tapped puddle flanges allow for easy modifications and adjustments as project requirements evolve.

Double Puddle Flanges

Description: As the pinnacle of watertight protection, double puddle flanges incorporate a dual-sealing mechanism that enhances their defense capabilities. This design makes them especially suitable for environments where robust water infiltration prevention is necessary.

Advantages: The enhanced watertightness of double puddle flanges makes them ideal for applications demanding maximum protection against water intrusion, ensuring operational integrity in challenging conditions.

Conclusion

In conclusion, while often overlooked, the puddle flange is an essential plumbing component that plays a critical role in safeguarding buildings from water damage. Its ability to create a watertight barrier around pipe penetrations ensures the longevity and structural integrity of the building. Whether in wet areas, basements, or external plumbing installations, puddle flanges are the unsung heroes that protect our homes and structures from the potentially damaging effects of water infiltration.

Next time you step into your bathroom or enjoy a dry and safe basement, take a moment to appreciate the role of the puddle flange, a small yet mighty component that quietly keeps water at bay and preserves the longevity of our living spaces.

Online Courses on Piping Design and Engineering

If you wish to dig deeper and learn more about elements of piping design and engineering then the below-mentioned online courses will help you to do so:

- Designing Piping Systems: Pipe Fittings Flanges Valves

- Piping Isometrics demystified through practical examples

- Flow of fluids through piping systems , valves and pumps

- The Complete Course on Piping Components for Oil&Gas Career

- Piping Design Engineering & Piping Isometrics Masterclass

- PG Diploma in Piping Design Engineering

- Click here for other relevant piping engineering courses

Hi great job keep posting, I am also mechanical engineer working in piping and pipe lines.