SmartPlant Instrumentation (SPI) is one of the foremost instrumentation engineering tools developed by Intergraph. Earlier, the same software was well-known as the Intools. The software acts as a single and widely used instrumentation application that is used in Engineering, Procurement, and Construction (EPC) Projects. Smart plant instrumentation helps in accessing and updating the instruments used in any plant for various tasks.

The software is used for managing and designing various activities including:

- Instrumentation management,

- Generation of instrumentation data sheet,

- Control valve and orifice plate sizing,

- Generating Loop diagram

- Programmable Logic Controller (PLC) wiring,

- Creating Hook-up drawings,

- PLC-DCS I/O assignment, etc

The majority of EPC firms use this instrumentation design tool. Smartplant instrumentation creates a single engineering design environment that creates and manages data required by instrumentation engineers. This software is an all-in-one solution for all Instrumentation and Process deliverables. The software package can seamlessly manage those data consistently throughout the design lifecycle.

What’s inside SPI and how does it work?

Project execution involves several tasks, to which many disciplines contribute. Executing these tasks in a systematic way makes the engineering deliverables better which will support the plant construction and operations.

SmartPlant Instrumentation is a platform that is progressing toward a module-oriented environment. This indicates this interface deals with the script at hand, for example:

Process module – Collect process data from SmartPlant P&ID. Edit information and add that data set into the instrument design basis wherever applicable.

Instrument Index module – Recall and expand the rule base instrument design basis from the P&ID into all physical instruments. This function performs as Process – Instrumentation synchronization.

Specification module – By using Engineering Data Editor create specific interfaces as well as user experiences that can be configured to perform the specific task – for example, to create instrument datasheets/specifications, which include SmartPlant Instrumentation data along with the data those are related to or coming from vendors specifications.

Wiring module – Build up the Engineering Data Editor for junction boxes, marshaling cabinet (including DCS and PLC), assigning the cable and wiring data script to auto-connect instruments with junction boxes, and junction boxes with cabinets. This task includes a loops check for connectivity. Here comes Instrumentation – Electrical synchronization.

This extended focus increased productivity and asset management quality.

How does Intergraph Data sharing work on SPI?

SmartPlant Instrumentation acts as a receiving engine from various data sources, which includes the process group, piping department, and electrical and instrumentation team. The outcome data then feeds into the piping group for the equipment or inline instruments, and interlocks for electrical, in addition to interfacing and interacting with vendor and third parties catalogs.

SmartPlant Instrumentation also supports operational activities, not only generating new and even as-built data also. SPI also offers a seamless interface for calibration with Fluke, and for maintenance scheduling interface with ERP providers such as the SAP platform.

Vendor data and catalog access are rapidly becoming more important to drive productivity and engineering design quality. Instead of finding and re-typing in SPI, you can easily access vendor data, for example, I/O card details for DCS, instruments under vendors’ scope like E+H, or valves from Rosemount/Emerson. SmartPlant Instrumentation makes it easy to get accurate data quickly.

How SmartPlant Instrumentation (SPI) contributes to the plant life cycle?

SmartPlant Instrumentation gains value for instrument-related workflow throughout the life cycle of the plant. SPI contributes to Engineering and Design, Procurement, Construction, Commissioning, Operations, and Maintenance.

Engineering and Design – SmartPlant Instrumentation helps to manage and create instrumentation data in a discrete database, which facilitates faster, synchronal engineering to reduce project manhours and cost. This software assures data accuracy, persistent deliverables, effective and optimized change management system. By creating various engineering rules this software maintains data integrity. Vast two-way integration with other software (like AutoCAD, Microstation, etc.) even with vendors (like Yokogawa, Emerson, etc.) to reduce manual entry and design time. Quality of data increases.

Procurement – Design data can easily be transferred from SmartPlant Instrumentation to Intergraph’s SmartPlant Materials, which can shorten the procurement cycle. Warehouses can easily maintain the purchase and change-over records in SmartPlant Materials, which makes procurement hassle-free.

Construction – The user can extract control panel drawing from the database. The contractor can start construction for the control panel and can modify it whenever required by simply modifying the database.

Commissioning – With the help of SmartPlant Explorer along with SmartPlant Instrumentation users can access data and test loop continuity. SmartPlant Explorer is more towards mark-up capability via the online Web.

Operations and Maintenance – SmartPlant Instrumentation along with SmartPlant P&ID acts as a single data package. The operator can easily access P&ID and instrument data simultaneously while operating the plant. These data are consistent, accurate, and current. So there is less chance of error, which makes maintenance easy.

Advantages of Smart Plant Instrumentation (SPI)

Plant engineers and operators use Smart Instrumentation Intools for asset performance management which translates to a variety of functions like power management, process automation, maintenance systems, safety, and asset optimization. The Intools software makes the sensors, electronics, and process diagnostics data to be centralized and aligned with tasks. This result in huge saving in labor hours and cost with improved compliance and consistency in managing change.

The major benefits that Smart instrumentation software packages provide are:

- Reduced Risk, downtime, and increased profit.

- Fully automated generation of engineering deliverables like wiring diagrams, loop diagrams, and specifications from centralized data.

- Improved performance of control system and associated documents.

- Rapid execution with custom design rules

- Improved work efficiency

- Reduced cost due to data leveraging and consistent design.

How SmartPlant Instrumentation gain value?

SmartPlant Instrumentation can easily facilitate small to very large projects. With a single source of all data offered, this software ensures that consistent changes are reflected, recorded, and flagged. This software platform helps to reduce project cycle manhours and gain value.

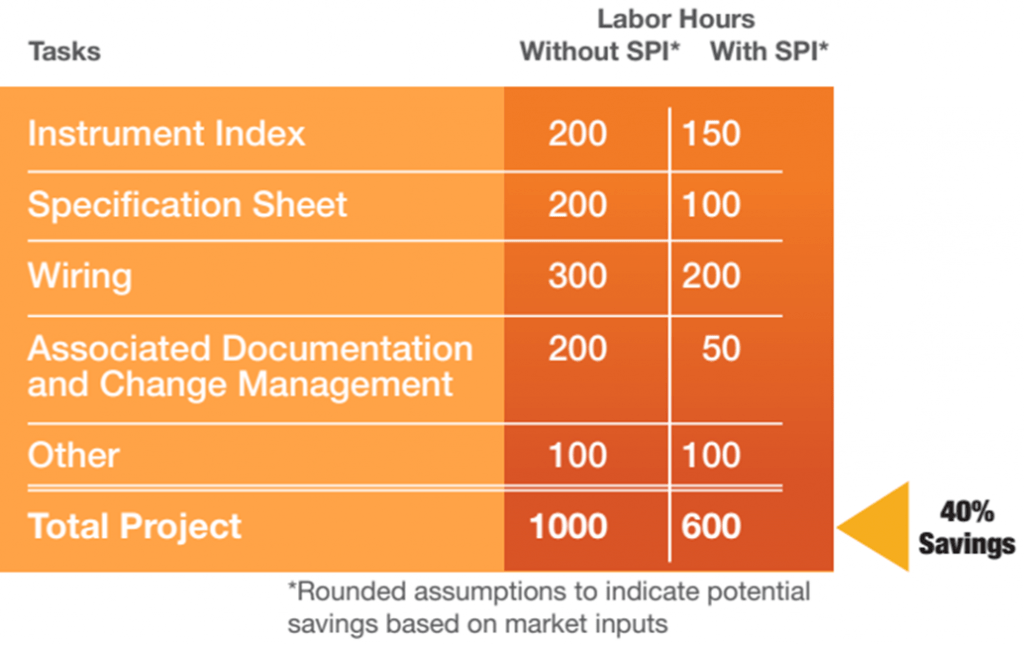

Intergraph calculated after facilitating a Large LNG project like 18 billion US$ in SmartPlant Instrumentation can save up to 40% of the project cycle manhours. Refer to the following figure

It seems a very useful software to solve operating control systems and instrumentation tools set up for oil and gas processes

how to share SPI data with client what are methods.