Principle of Filled Thermal System

This works on the following principle: Liquid or Gas expands when heated and this change in volume is used for measurement.

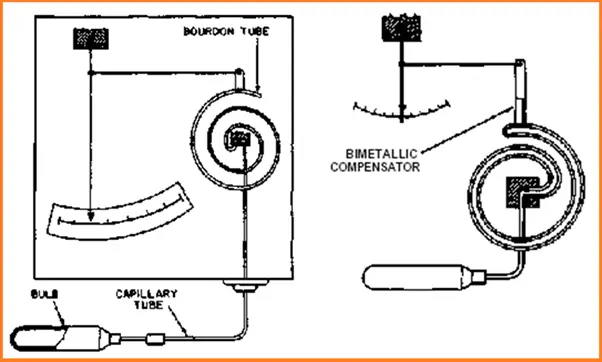

A filled thermal system is basically a pressure gauge (generally bourdon type) with a small-bore tubing connected to a bulb acting as a temperature sensor. The complete system is gas-tight and filled with gas or liquid under pressure.

Filled System Selection Criteria

The selection is typically application-oriented.

- Ambient temperature compensation.

- Scale graduations.

- Bulb size and tubing lengths.

- Bulb material.

- Over-range capacity.

- Torque requirements.

- Selection of filling fluid/gas.

Impact due to Ambient Temperature

Ambient temperature compensation-

- Thermal expansion will have a small impact on the reading.

- If the range is narrow or the bulb is small and the capillary long then full compensation is required.

- Compensation is done either using a bimetallic compensator or by duplicating the spiral and capillary.

- A good practice is to have a large bulb diameter.

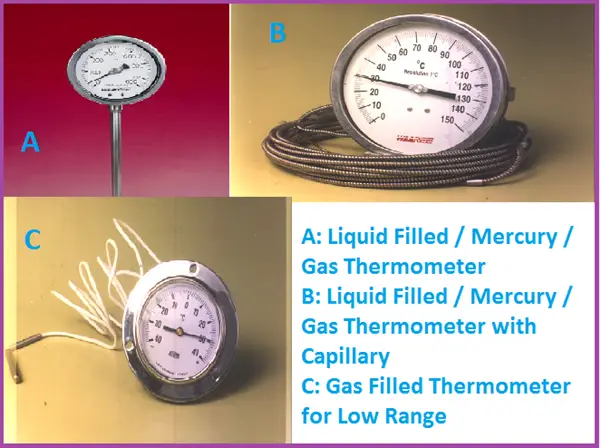

Liquid filled system

- Here the complete system is filled with a liquid (other than mercury) and operates on the principle of liquid expansion.

- The filling liquids are – Inert Hydrocarbons like Xylene (C8H10), which has a coefficient of expansion 6 times that of mercury and makes smaller bulbs possible.

- The criteria are that the pressure inside the system must be greater than the vapor pressure of the liquid to prevent bubbles of vapor from forming inside the spiral.

- Also, the filling liquid should not solidify.

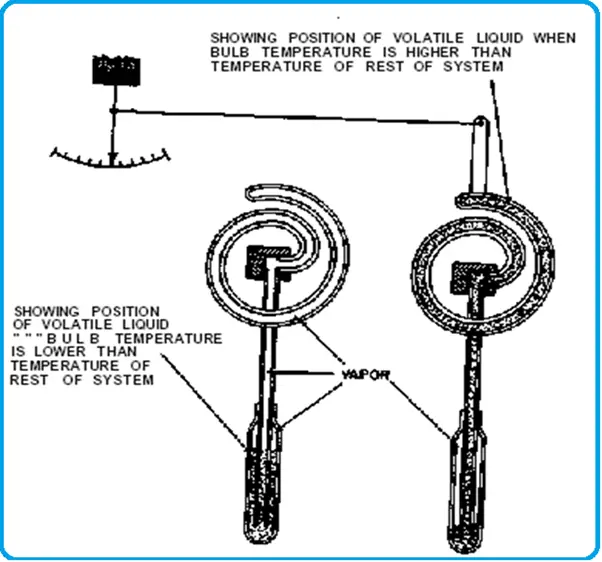

Vapor filled system

- Here the filling medium is in both liquid and gaseous form.

- The interface between the two must occur in the bulb and this will move slightly with temperature affecting the pressure.

- The bulb will be mostly filled with gas while the capillary and spiral would contain liquid.

- This is not recommended when the ambient temp. is near to the measured temp.

Gas-filled system

- The operating principle for gas-filled systems is that in a perfect gas confined to a constant volume, the pressure is proportional to the absolute temperature.

- Nitrogen is the normal filling media. However, for ranges above 427 Deg. C, this is avoided, as it interacts with steel, which is the bulb material.

- For Low temperatures, Helium is used.

Mercury filled system

- This is a very common method for measurement.

- The response is fast and accurate.

- The ambient temperature compensation is less of a problem, as mercury is incompressible.