Pipe clamps are widely used for supporting suspended pipes. They are also used to work as clamped pipe shoes. Pipe clamps can be defined as bolted circular or semi-circular pipe attachments that clamp around a pipe and connect the pipe with other assembly components for proper support. These piping clamps transfer loads of the piping system to the structure. A wide variety of piping clamps are available to use as pipe support attachments.

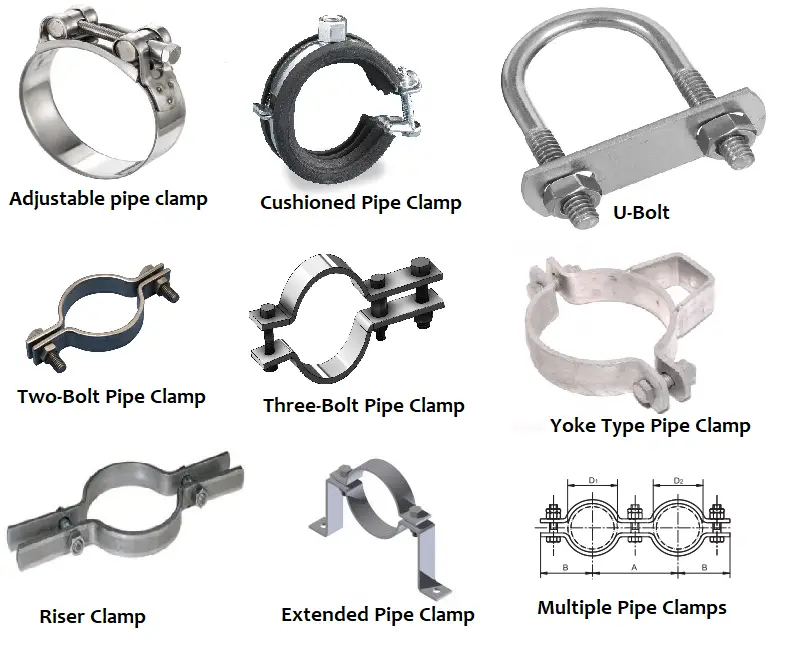

Types of Pipe Clamps

Depending on the purpose, materials, function, use, etc, a wide variety of piping clamps are used in industrial applications. Some of the different types of pipe clamps are explained below:

1. Adjustable Pipe Clamps:

Mostly made from Steel, plastic, or aluminum, these types of piping clamps have the ability to adjust themselves as per the required pipe diameter. They can be easily tightened or loosened as per the pipe OD. As these types of pipe clamps can be universally used for different pipe diameters, they are cost-effective.

2. Cushioned Pipe Clamps:

Containing a cushioning material these type of pipe clamps helps in avoiding galvanic corrosion as metal-to-metal contact is prevented. Widely used for bare pipes, these pipe clamps shall be selected depending on the pipe temperature as the cushioning material should sustain that temperature.

3. Rigid Clamps:

Simple in construction, Rigid clamps are usually made from steel or iron. They are available as single-body pipe clamps or two-piece pipe clamps and can easily be screwed.

4. U-bolts:

U-bolts are the most widely used type of pipe clamps. U-bolts are extensively used for small-bore piping. They are used to work as rest+guide+hold down or rest+guide+hold down+line stop for small bore piping systems. For pipes with a diameter exceeding 8 inches, their application is reduced to a great extent as the piping loads increase with the increase in pipe sizes.

5. Two-Bolt Pipe Clamp:

Two-bolt pipe clamps are used for hanging bare pipes without any insulation. Their load-carrying capability is usually not large.

6. Three-Bolt Pipe Clamp:

Three-bolt Pipe Clamps are used for suspending insulated lines carrying high-temperature fluids. The length of the clamps on top of the pipe is increased to accommodate the 3rd bolt which allows the attachment of the pipe clamp outside the insulation. The load-carrying capability of three-bolt pipe clamps is relatively higher than two-bolt pipe clamps.

7. Yoke-Type Pipe Clamp:

For hanging of high-temperature horizontal insulated pipes, yoke-type pipe clamps are used. These types of pipe clamps can easily support pipes with 4″ – 6″ insulation.

8. Riser Pipe Clamps:

Riser Pipe Clamps are used to support lines without the use of hanger roads. The pipe loads are transferred by resting both ears of the clamp on the floor or structural member. These types of pipe clamps are not recommended for higher temperatures.

9. Pipe Clips:

Also known as pipe straps, pipe clips are used to support horizontal or vertical lines by bolting the clip directly to a structure.

10. Heavy-Duty Pipe Clamps:

Heavy-duty piping clamps are specially designed to support higher piping loads. Most of the pipe clamps are designed in both standard and heavy-duty variants to address different load requirements.

11. Extended Pipe Clamps:

In some applications, the bottom piece of the pipe clamp can be extended and configured to use as a pipe support. These types of piping clamps are known as extended pipe clamps.

12. Multiple Pipe Clamps:

In certain special applications, two or more pipe clamps can be joined together or manufactured to use multiple pipe clamps to support more than one pipe. Multiple pipe clamps are specially fabricated to suit the site requirements.

Selecting a Pipe Clamp

Selecting a pipe clamp for a specific application required considering various parameters. Some of these factors are:

Pipe Material:

Normally the clamp material should be compatible with the pipe material. For example, a SS pipe needs an SS clamp to avoid galvanic corrosion.

Pipe Temperature:

Pipes expand or contract based on the temperature variation of the pipe material. So, the clamps selected should be able to withstand those temperature fluctuations.

Load Bearing Capability:

Clamps should be selected based on the applicable piping loads. Normally, all manufacturer’s catalogs specify the maximum load-carrying capacity of both standard and heavy versions of pipe clamps. So, piping clamps must be selected after calculating the pipe support loads. Normally, clamps are avoided for axial load applications like the application as line stops. But in some small-size lines fixed u clamps are used as line stop supports. Also, sometimes clamped pipe shoes are used as line stops. In those cases, the magnitude of axial loads must be checked and suitable additional arrangements must be done if required.

Pipe Outer Diameter:

Pipe size or outer diameter also affects the pipe clamp selection. Usually, clamps are manufactured for a certain minimum to maximum pipe diameters. So, while selecting pipe clamps those need to be checked in the manufacturer’s catalog.

Working Environment:

The type of pipe clamps is also affected by the working environment where the piping clamps will be installed. As pipe clamps will be exposed to the environment, the proper coating must be provided to avoid corrosion.

Special Requirements:

Pipe clamps may require special functions like having rubber lining or absorbing noise. So, according to special functions that need to be performed clamps need to be selected.

Deciding the Size of Pipe Clamps

The size of pipe clamps is decided based on:

- Pipe outside diameter: As pipe OD is fixed for metallic pipes, clamps are decided based on the pipe’s outer diameter. For plastic pipes however the OD may vary from manufacturer to manufacturer which will decide the selection of piping clamps.

- Special Consideration: Sometimes, it may be required to use clamps over pipe insulation, in those cases insulation OD must be calculated while deciding on pipe clamp size.

Pipe Clamp Materials

Pipe clamps are manufactured of a wide range of materials like:

- Carbon Steel

- Stainless Steel

- Plastic

- Copper

- Brass

- Aluminum

- Alloy Steel

- Chrome/Chrome-Plated pipe clamps, etc

Features of Pipe Clamps

Most pipe clamps provide the following features:

- Simple Operation

- Easy installation

- Adjustable in a small range

- Nice appearance

- The temperature range is decided by the clamp lining being used.

- All pipe clamps usually have impact resistance.

- Quick and easy pipe installation and layout.

- Shock-absorption property

- Vibration dampening property

- Acoustic reduction property

- Heavy torque

- Suitable for small and large-diameter pipes, etc.

Applications of Pipe Clamps

Pipe clamps are widely used in the piping and plumbing industry. Some of the common uses of pipe clamps are as follows:

- To fasten and fix pipes with structures to provide support.

- To provide fast, safe, economic service and installation in a piping system.

- Pipe clamps can also be used in a wide range of fastening applications.

- The pipe clamps can also be used to absorb shock, dampen vibration, and reduce noise.

Online Video Courses on Piping Support

To learn more about piping support design and engineering you can opt for the following video course.

Dear sir!

All the articles related to your piping are very high. We are getting to learn a lot from this.you are doing a great job.

Thanks

Dear Anup Kumar,

I appreciate the step by step details that you provide on all of your Blog. It’s been very informative and educative. Thanks you for that.

Would it be possible to provide the International standard number ( like ISO/ASME/BS/DIN ) that these Clamps conforms to..?

Thanks and Regards

you are great. May God bless you abundantly

Great work

Hello sir

Your blog is great , kindly keep continue.

But also upload image in blog with related blog.

Hello ! Anoop,

Would like to reach you out on email.

Hello ! Anoop,

Would like to reach you out on email.

Love your information, it’s helping me at my work as i work in China in a pipe support company. great info