Water Hammer Basics

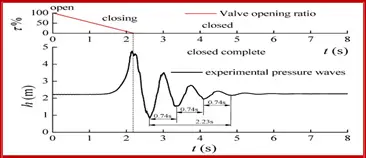

Water hammer, Pressure Surge, or hydraulic shock, is a term for the destructive pressure increase and accompanying shock wave that takes place in pipeline or piping systems when the flow rate of liquid changes suddenly. A large vapor pocket is formed because of this within the pipeline; and when this vapor pocket collapses, a highly powerful, bidirectional pressure wave propagates away from the origin at a very very high speed. In extreme situations, the magnitude of this shock wave can reach up to 100 times the closure velocity of the pocket. In the actual scenario, This huge force can force the pump shell to rupture.

What Can Cause Water Hammer?

Sudden flow restriction due to valve closure or pump trip, load shedding, etc. is the most popular reason behind water hammer phenomena. If any of the above is the actual cause, the pump operators can easily reduce or even eliminate the possibility of water hammering by using proper valve closure procedures.

However, the pumping environment can also be one of the reasons for its creation. For example, In the phosphate industry pressure surge in pit pump applications are the most common. In such cases, during operation, the suction pipe can become blocked, but not during valve closure. While quick filling of long pipelines Surge can occur where the flowing fluid and the static fluid meet.

Predicting Water Hammer

Since a water hammer or surge manifests as a shock wave, it is really very difficult to predict its point of origin or source until a rupture arises. Anyone or anything in close proximity to these pipelines is at high risk in the event of a water hammer and the resulting pipeline movement, so pump operators have to be extra cautious when there is any chance of a water hammer.

Water hammers may not be so destructive in all situations. In less severe cases, a banging or hammering noise is heard and it may also bend or move the pipe or its support.

Difference between Water Hammer and Cavitation

Sometimes, a water hammer or surge is confused with pump cavitation, but both are two different phenomena. However, cavitation can easily increase the potential risk of water hammer. In normal practice, cavitation itself is not always so destructive. The main difference between the two is that Cavitation involves the implosion of many small, localized vapor pockets whereas the water hammer involves the collapse of a single large vapor pocket. Cavitation damage builds up over time before causing a part to fail; conversely, a single instance of water hammer may cause catastrophic damage.

Extreme cavitation can occasionally result in a water hammer. For example, when cavitation is not severe enough to stop operation entirely but severe enough to impede pumping, a vapor pocket is expected to form in the pipeline. When pumping resumes, the pocket collapses, thereby causing a water hammer.

How to Stop Water Hammer

The main step towards reducing the water hammer possibility is by educating the pump and valve operators or plant operators.

As it is well-known that quick valve closing is the ultimate cause of water hammer generation, it is the responsibility of the valve operators to close the valves in the correct way as mentioned in the operating manuals.

For situations where the pump suction gets blocked, plant operators must stop the pumps following the same sequence of steps that they would use while a controlled shutdown is planned. In such cases, the vapor pocket will close at the minimum possible velocity this, in turn, will limit the magnitude of the shock wave to a minimum.

Operators should attempt to control the suction pipe movement and position it at the pipe entrance to keep it free from blocking. However, if there is a slump in the mining or dredging face, the pipe may still become blocked. Such risks can be carefully considered before moving the suction pipe entrance, as it may cause a water hammer.

So, by identifying and understanding the causes of surge or water hammer in pumps, and by following proper operating procedures, operating manuals, and vendor guidance notes, plant operators can prevent a disaster from happening due to water hammer. However, the pumping environment also plays an important role and situations may require expert help.

Some more ready references for you…

Introduction to Pressure Surge Analysis

Understanding Centrifugal Compressor Surge and Control

Pipe Stress Analysis from Water Hammer Loads

Nice info. I am looking for some freelancer or consultant who can do water hammer analysis & provide solution if any. if Any. Please whats app me on +91 990 990 6848

whatsapp on 8141404000

hi i have doubt regarding this surge analysis and water hammer analysis is same.

also what are the inputs required to do analysis in caesar ii

Kindly check the slug flow analysis article…. After getting the surge force, the analysis steps are the same as slug force…Static equivalent method…https://whatispiping.com/static-analysis-of-slug-flow/

Wonderful explanation. Not sure what the proper terminology is, but growing up we had the lever like valve on the bathroom faucet, instead of the hot and cold knobs. My brothers and myself at first had a tendency to slam the lever down when we shut it off. This would cause a knocking sound in the pipes in the basement, like someone was literally down there swinging away with a hammer. When my father caught us doing it he’d chew us out. I quite quickly started modulating my handling of the faucet. My brothers not so much. Luckily after they moved out the problem was solved, except on holidays. Eventually he just replaced the lever for the two hot and cold knobs. Never had a problem with knocking after that. Later on I ended up taking Fluid power courses in college. I learned a tiny bit about cavitation. Somehow I’d gotten the image in my mind that cavitation was the same thing as knocking, or water hammer. Today I ended up searching knocking vs water hammer vs cavitation, which eventually led me to this page. Thank you for clearing up the misconception.