Many times, as stress guys, we come across complicated and long piping layouts to be modeled in CAESAR II. These may include parallel pump suction/discharge piping, inlet/outlet piping to/from multiple Coke Drums, and outlet piping from two sides of Fired Heaters.

In the majority of the cases, we found that these parallel paths are either absolutely similar, or mirror each other, with respect to pipe length, fittings, valves, supports and hangers, and other details.

In case we go for modeling these parallel or similar paths separately, not only it consumes additional man-hours, there is always a chance of human error.

Thus, if we can identify the lines having similar or mirror geometry, we can model once, and make copies as required.

Even in case, the paths are similar but not parallel, e.g. discharge lines two groups of pumps, seating orthogonally to each other, we can re-use the portion of the model with suitable rotation of duplicated path. Now, we will cite the example of a pair of process pump suction lines.

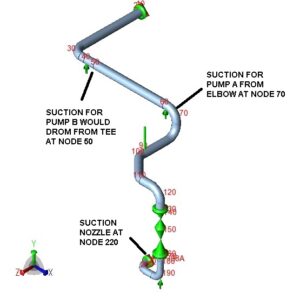

Fig. 1

Now, we need to model another suction branch from Node 50, by duplicating Elements between Node 70 to Node 220.

Now click on ‘List Input’, and select the Elements between Node 70 to Node 220. Then right-click, select ‘Block Operation’, and then ‘Duplicate’.

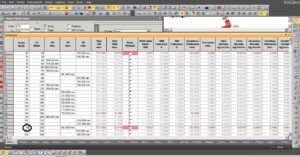

Fig. 2

Now, choose the option as ‘Mirror Y-Z’ (this needs to be assessed beforehand). And select ‘Insert Copied Block’ as ‘At End of Input’. Put Node increment as ‘150’, so that Node 80 would be incremented to 230 and so on, and finally Node 220 would be incremented to 370.

Fig. 3

Now, at Row 22, change the ‘To’ Node No. to 50.

Fig. 4

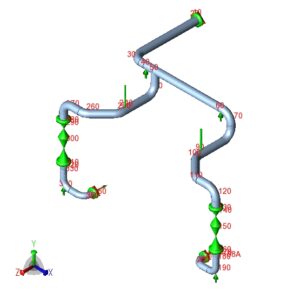

Now, the complete model with Suctions for both Pump A and Pump B is ready for analysis.

Fig. 5

Note: This method would transfer all the elements and properties of the first branch, except Node Names and Line Numbers, which the user needs to update manually.

Dear friend,

Please I need your help. I am a beginner in handling Caesar II. I have inserted an element (tube) between two nodes. Despite using the element eraser I cannot erase that inserted tube. How can I solve? I want to delete that tube but I can’t. Thanks for your help.

Sincerely,

Oscar Antonio