Anchor bolts attach and secure structural elements to concrete structures. In general, anchor bolts are used to secure skids, equipment, and structural members to concrete. One end of the anchor bolts is embedded in the concrete, while the other end is kept exposed. The exposed end is usually threaded to attach structural elements or the equipment. In this article, we will explore the different types of anchor bolts, their uses, and selection criteria.

What is an Anchor Bolt?

An anchor bolt is a mechanical fastener that fixes one or more objects to a concrete surface. They are heavy-duty fasteners and are widely used by civil engineers. The unique design of anchor bolts keeps the equipment and structures stable and in place.

Types of Anchor Bolts

Depending on the installation requirements, Anchor bolts used in industrial projects are categorized into the following two groups:

- Cast-in-Place anchor bolts and

- Post-Installed anchor bolts

Cast-in-Place Anchor Bolts

From the name itself, it is quite clear that the cast-in-place anchor bolts are cast directly into the concrete material. They are the simplest but the strongest of all anchor bolts used. This type of anchor bolt is placed in the wet concrete that becomes fully secured when the concrete cures and hardens.

Anchor bolts of cast-in-place types are again categorized into various groups. The most common types of cast-in-place anchor bolts are:

- Drop-in Anchor Bolts

- Bent-bar anchor bolts (J-bolts or L-Bolts)

- Plate Bolts

- Sleeve Anchor Bolts

- Headed Anchor Bolts

- Swedge Bolts

Drop-in Anchor Bolts:

Drop-in bolts are quite simple and straightforward. When the concrete slab is wet, a cork-screwed sheath is inserted into the mixture keeping it flush with the slab’s surface to insert a matching bolt when the mixture dries.

Bent-bar Anchor Bolts:

These are basically steel rods or bars bent into either L or J shapes. These types of anchor bolts have threads at one end with the other bent end bent is embedded into the concrete. J-bolt and L-bolt anchor bolts are quite common in signposts, poles, heavy equipment, tooling, and other steel structures.

Plate Bolts:

Plate bolts usually consist of a T-shaped bolt mounted upside down into wet concrete. The “T” end of these bolts is provided with a corkscrewed section for mounting a nut and a circular plate. This type of anchor bolt is also known as a Double End rod with a Plate. The plate is usually welded to the anchor bolt or a nut is embedded in the concrete.

Sleeve Anchor Bolts:

Resembling similar to standard drop-in anchors, Sleeve anchor bolts are primarily used in bricks and have a longer length.

Headed Anchor Bolts:

Headed anchor bolts have a forged hexagonal or square head on one end which is embedded in the concrete.

Swedge Bolts:

They are basically round bars with thread on one end and “swedged” on the other. The term “swedge” signifies the numerous indentions made on the bar for the purpose of getting a better grip on the concrete. This type of anchor bolt is commonly used in the construction of girders and piers.

Post-Installed Anchor Bolts

Post-installed anchor bolts are installed after the concrete has already been laid down at the site. In this type of anchor bolt, a hole is required to be bored into that concrete surface and the screw is installed.

Some common post-installed anchor bolts are as follows:

- Lag Screw

- Hammer Driver Pin

- Toggle Wing

- Double Expansion Shield

- Wedge

Lag Screw:

This type of anchor bolt is quite similar to plastic wall anchors and is easy to install. The lag Screw mounting system uses a metal sheath that expands when the lag screw is inserted into it.

Hammer Driver Pin:

Resembling a specialty nail, hammer driver pins are used for mounting thin materials onto concrete. The anchor contains a skinny metal sheath for inserting into the floor prior to being filled with a hammer driver pin.

Toggle Wing:

A toggle wing is good when working with a hollow wall. This type of anchor bolt has a long corkscrewed bolt with a hinged wing mechanism. Both of them are inserted through a pre-bored hole for combination. The wings expand after passing through the hole. They are used for holding smaller weights.

Double Expansion Shield:

A double expansion shield anchor bolt uses two parallel expansion points within a regular shielded anchor point. This type of anchor bolt doubles the amount of contact between the sheath and the material which in turn reduces the pressure at each point.

Wedge Anchor Bolt:

Wedge Anchor bolts consist of a specialized bolt featuring a moving wedge device at its base. Because of this, these types of anchor bolts tighten upward towards the fastening nut and the nut is fastened downward toward the surface level.

Depending on the working philosophy anchor bolts are classified into two types. They are:

- Mechanical Anchor Bolt and

- Chemical Anchor Bolt

Mechanical anchor bolts

use the frictional force to fix themselves in location. Once installed, the mechanical anchor bolts expand which grips the base material tightly and act as an anchor. All the above anchor bolts explain above are mechanical anchor bolts.

Chemical Anchor Bolts

Chemical anchor bolts provide more flexibility as compared to mechanical anchor bolts. In this type, a resin is injected into the hole before inserting the stud. The chemical resin fills all irregularities of the hole and makes it waterproof and airtight. The bond produced by chemical anchor bolts is stronger than the base materials. Examples of chemical anchor bolts are:

- Polyester chemical anchors

- Vinylester chemical anchors

- Epoxy acrylate chemical anchors

- Pure epoxy standard anchors

- Resin anchors

- Chemical threaded anchor rods

- Powder–actuated anchors

- Hybrid chemical anchors

Selection of Anchor Bolts

Choosing or Selecting the Best Anchor Bolt depends on various factors. Some of the important parameters to consider while anchor bolt selection are:

- Size of anchor bolt hole: As the diameter increases, the load-carrying power also increases.

- Length of the anchor bolt: The deep the embedment inside the concrete, the more load-holding power. The National Concrete Masonry Association provides a rule of thumb for the anchor bolt length embedded in the concrete. As per them, the effective embedment length must be greater of (4*d or 2′′).

- The base material of the object.

- Environmental conditions of the structure

- Maximum load or weight that the anchor can support

- Type of load: The holding power of anchor bolts slowly decreases for vibrating and shocking loads.

- Strength of the anchor bolt material.

- Type of the concrete

- The size and location of the fixtures

- The desired appearance of the finished product

- Anchor spacing requirement.

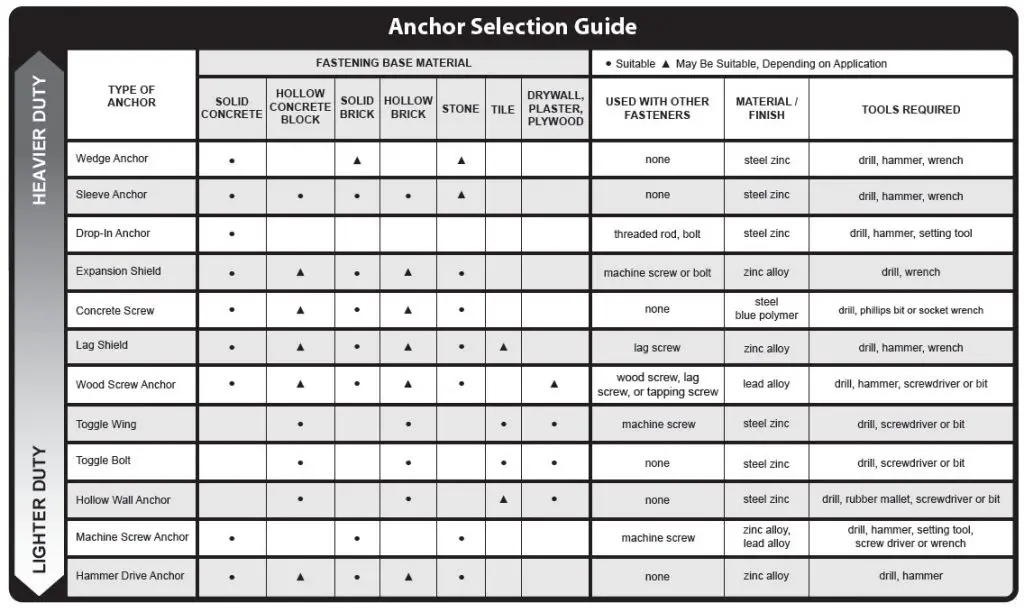

The table in Fig. 1 by americanfastener.com can serve as a reference for selecting mechanical anchor bolts.

Grouping Anchor Bolts

To increase the load capacity of anchor bolts, they are grouped. However, the mechanical behavior of the group of anchor bolts depends on

- The spacing between anchor bolts and

- The difference in applied forces.

Anchor Bolt Failure Modes

The anchor bolts can fail by any of the following failure modes:

- By tensile loads, examples include breakage of the anchor bolt steel, pull-out from the hole, etc.

- By shear loads, examples are Concrete edge failure, steel failure, and pry failure.

- By combined action of tensile and shear loads.

Uses of Anchor Bolts

Anchor bolts are used to attach and secure structural and non-structural elements to the concrete. They are used almost in every industry. Some of the industries where anchor bolts find wide applications are:

- Chemical, Petrochemical, Oil and Gas Industry: For fixing various pieces of equipment, support foundation, and other structural members.

- Power and Steel Industry.

- Building Services.

- Hospital industries: To install equipment on ceilings or walls.

- Railways and the Aviation industry.

- manufacturing plants

- Pipeline industries.

- Pharmaceutical and food processing plants.

- Nuclear industries.

Hi There,

Thanks for sharing detailed information about Anchor Bolts.

Are there any types of concrete anchors which are recommended for use when the spacing between anchor bolts will be less than (10 * the diameter of the anchor bolt) ?

Good morning, I am an Italian technician who works for a company that builds aluminum windows and ships them to the United States. I have a question to ask, we have always used the cleaner Anchor bolts outside the windows wall, this time instead they ask us to install them on the inside of the window. Is there a precise rule on this installation? or does it depend on the manufacturer’s preference?