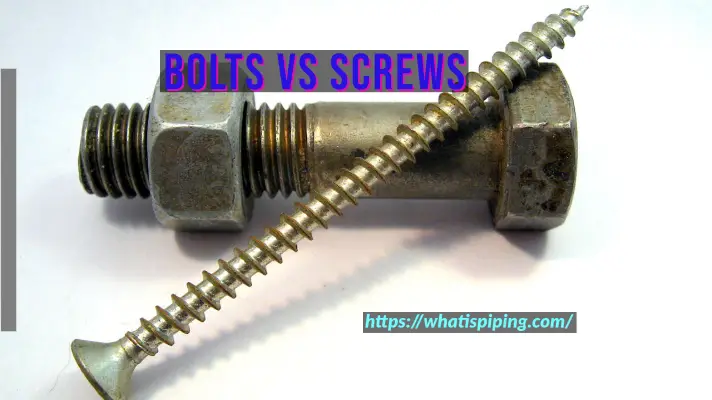

Bolts and Screws are two unique mechanical fasteners used to hold two or more components together. From construction and machinery to household projects, Bolts and screws are used in a wide range of applications. Many believe that bolt and screw refer to the same fastening hardware as they look similar and possess quite similar features. Even with the naked eye, bolts vs screws seem to be the same as much difference between a bolt and a screw is not observed. But as per engineering applications and understanding, there are differences between bolts and screws. In this article, we will explore the characteristic features of bolts vs screws.

What is a Bolt?

A bolt is a mechanical fastener with a cylindrical threaded shaft used to assemble unthreaded objects. Usually, the term bolt refers to a fastener having only part of its shaft threaded. In general, a bolt is inserted through parts having unthreaded holes and then a nut is screwed to provide a clamping force and prevent axial movement.

A bolt is defined as a type of threaded fastener with an external male thread. It is designed to be used in conjunction with a corresponding nut to hold objects or materials together. Bolts are typically cylindrical with a helical thread wrapped around their length, and they often feature a hexagonal head that allows for tightening with a wrench or spanner. Bolts require a pre-drilled hole to be inserted through the materials being fastened. The primary function of a bolt is to create a clamping force that secures the components in place when the nut is tightened.

The part of the shaft that is unthreaded is termed ‘the shank’. The bolt head and nut prevent axial movement and the shaft of the bolt restricts the radial movement of the parts. The unthreaded shank provides a more precise and less abrasive interface with the parts. At the same time, the shank does not contain stress concentrations because it is unthreaded.

What is a Screw?

A Screw is a mechanical fastener having a threaded cylindrical or tapered shaft used to engage parts with threads. Screws with tapered shafts are self-threading means the thread cuts into the material while the screw is turned. Screws have their entire shaft threaded.

A screw can be defined as a type of threaded fastener characterized by an external helical ridge, or thread, that wraps around a cylindrical shaft. It is designed to be inserted into a material by turning, creating its internal thread within the material as it advances. Screws typically have a head with a specific drive type to facilitate insertion and removal using a corresponding tool, such as a screwdriver or power drill. Unlike bolts, screws do not usually require a nut and can be used to fasten materials directly. The primary function of a screw is to hold objects together by pulling them tightly against the surface into which the screw is driven, providing a secure and often permanent connection.

The friction at the threads is the force that keeps the parts securely fastened. This friction is generated by the applied torque in the case of machine screws whereas for self-tapping screws the radial expansion of the hole creates a major part of this friction.

Bolts vs Screws: Differences between Bolts and Screws

Now that Bolts and Screws are clear, let’s find out the differences between them.

1. Bolts vs Screws-Construction

1.1 As per the construction of Bolts and Screws, Bolts usually have partially threaded uniform cross-sections but Screws can have tapered shafts. So the cross-section may vary according to the length of the screws. Also, for screws, the entire length is threaded and the tip of the screw is often pointed to penetrate the material.

1.2 Bolts usually have a hexagonal or square head that can be tightened or loosened with a wrench whereas Screws come with various head types, such as flat, Phillips, or hex, each designed for different driving tools.

1.3 The threads on bolts are generally coarser and have a larger pitch compared to screws. On the other hand, Screws typically have finer threads with a smaller pitch, allowing them to grip tightly into the material they are driven into.

2. Bolts vs Screws-Application

2.1 To secure bolted joints, nuts are required whereas the screws work on their own without the requirement of nuts. Sometimes washers are also added in bolts. The nut and bolt combination creates a strong, stable joint, ideal for heavy-duty applications.

2.2 During the installation of a bolted joint, the torque is applied at the nut whereas for screws the torque is applied at the screw.

2.3 Bolts are always used with un-threaded parts whereas Screws are used with threaded parts. In case the thread is not available, the self-tapping screws create those during installation.

2.4 Bolts are commonly used in construction, automotive, and machinery industries where high strength is required. They are also prevalent in situations where disassembly and reassembly are necessary. On the other hand, screws are typically used in woodworking, metalworking, and in scenarios where quick assembly is needed. Screws are common in household items, appliances, and light-duty fastening tasks.

3. Installation Method

Bolts require a pre-drilled hole and are often installed using a wrench or socket set. The process involves inserting the bolt through the material and securing it with a nut on the opposite side. Whereas, screws are installed by driving them into the material with a screwdriver or drill. They usually do not require a pre-drilled hole if they are self-tapping.

4. Screws vs Bolts-Clamping Force

The nut and bolt assembly creates a very high clamping force keeping the member in between under compression. On the other hand, Screws are used where the clamping force requirement is low. Bolts are typically stronger than screws.

5. Bolts vs Screws-Load Carrying Capability

5.1 The reliability of bolted joints is very high. Bolts can carry high loads. For increasing load-carrying capabilities, larger-size bolts are used in construction industries. But, Screws have a lower load-carrying capability and they are not available in larger sizes. The reliability of Screws is moderate.

5. 2 Bolts distribute the load evenly across the joint whereas may not distribute the load as evenly as bolts.

6. Other differences between Bolts and Screws

6.1 As nuts are used to tighten a bolt, the length of the bolts must be more than the width of the parts through which it is protruding. On the contrary, the length of the screws is usually less than the width of the assembled components.

6.2 Bolts are usually fastened using a spanner or other tools whereas Screws are normally tightened using a screwdriver or a driver bit.

6.3 Removing a bolt is usually easier than removing a screw.

6.4 The cost of Bolts is usually higher than that of Screws. So, Bolting is a costlier option whereas screws are cheaper.

The above discussion can be summarized in a tabular format as follows:

| Feature | Bolts | Screws |

|---|---|---|

| Design and Structure | Bolts have uniform cylindrical bodies and hexagonal heads. | Screws have a tapered body and various head types. |

| Application and Use | Construction, machinery, automotive. | Woodworking, metalworking, plastics. |

| Thread Type and Pitch | Coarse threads, larger pitch. | Fine threads, smaller pitch |

| Installation Method | Requires pre-drilled hole and nut. | Can be installed directly or in a pre-drilled hole. |

| Strength and Load-Bearing | High strength, suitable for heavy loads. | Good holding power, lower strength. |

| Removal and Reusability | Easy to remove and reinstall. | Depends on material, potential thread stripping in soft materials |

A range of Bolts and Screws are available for engineering applications. Different types of Bolts include anchor bolts, arbor bolts, elevator bolts, hanger bolts, hex bolts, J bolts, lag bolts, rock bolts, shoulder bolts, and U bolts; which are available in a wide range of materials like steel, stainless steel, brass, bronze, nylon, plastic, etc. Similarly, different types of screws are hip-board screws, particleboard screws, deck screws, drive screws, hammer drive screws, drywall screws, eye screws, dowel screws, wood screws, twin-fast screws, security head screws, and sheet metal screws; the material of these screws also vary depending on the application.

Frequently Asked Questions for Bolts and Screws

Should I use bolts or screws?

Using bolts or screws will be decided based on the applications. Screws are used for medium holding power whereas bolts are the best for heavy-duty projects. In general, screws are used for sheet metal, plywood, drywall, pressboard, deck planks, etc. Alternately, bolts are usually used for beams, concretes, and studs.

Are screws and bolts the same?

No, bolts and screws are not the same. The principal difference between bolts and screws is that screws are used for threaded objects and bolts for unthreaded objects.

Which is stronger: Bolt or Screw?

Bolts have greater holding strength as compared to screws. This is the reason that bolts are used for high-load-bearing applications.

Do bolts hold better than screws?

Answer: Bolts generally hold better than screws, especially in applications requiring high strength and load-bearing capacity. Bolts are designed to be used with nuts, providing a strong clamping force and distributing load more evenly across the fastened materials. This makes them ideal for heavy-duty applications. However, the choice between bolts and screws depends on the specific requirements of the project, including the type of materials and the desired permanence of the assembly.

What makes a bolt, not a screw?

The primary difference between a bolt and a screw lies in their usage and design:

- Bolts are used with nuts and require a pre-drilled hole. They have a uniform cylindrical body with a coarse thread and typically a hexagonal head for tightening with a wrench.

- Screws can create their threads in materials and do not require a nut. They usually have a tapered body with a variety of head types for different screwdrivers. Screws are often used directly in materials without pre-drilled holes, making them versatile for various applications.

What are the disadvantages of bolts?

While bolts are strong and reliable, they have a few disadvantages:

- Installation Complexity: Bolts require pre-drilled holes and nuts, making installation more complex compared to screws.

- Time-Consuming: The process of aligning the bolt with the hole and threading the nut can be time-consuming.

- Space Requirements: Bolts and nuts need sufficient clearance around the assembly for tools to tighten and loosen them.

- Cost: Bolts and nuts can be more expensive than screws, especially in large quantities or in specialized applications.

Can I use a bolt instead of a screw?

In many cases, bolts can be used instead of screws, particularly where high strength and secure fastening are required. However, using bolts requires pre-drilled holes and sufficient space for nuts and tools. For applications where ease of installation and less frequent disassembly are priorities, screws may be a more suitable choice. The decision depends on the specific needs of the project, including the materials being joined and the required durability.

What is a bolt without a head called?

A bolt without a head is commonly referred to as a stud. Studs are threaded rods used to join components together, typically by screwing into a tapped hole in one part and accepting a nut on the other end. They provide strong and permanent connections in various mechanical and structural applications.

Do bolts weaken over time?

Bolts can weaken over time due to several factors:

- Corrosion: Exposure to moisture and chemicals can cause bolts to rust and degrade.

- Fatigue: Repeated loading and unloading cycles can lead to metal fatigue, reducing the bolt’s strength.

- Wear and Tear: Frequent tightening and loosening can wear down the threads, compromising the bolt’s integrity.

- Environmental Factors: Extreme temperatures and other environmental conditions can affect the material properties of bolts, potentially weakening them.

- Regular inspection and maintenance are crucial to ensure the longevity and reliability of bolts in critical applications.

What is the weakest part of a bolt?

The weakest part of a bolt is typically the threaded portion. This is where stress concentrations occur, especially at the root of the threads. The threads are more susceptible to damage, wear, and fatigue compared to the smooth shank. Properly torquing bolts and ensuring correct installation can help mitigate these issues and maintain the bolt’s strength and performance.

It’s good to know that bolts can carry high loads and are much better suited to the job than screws. My husband plans on building a small treehouse for our toddler to play in and isn’t sure what type of metric fastener he should get for his construction. Even if the treehouse will only be for our baby boy it’ll still be good to know it can take the weight of an adult for safety reasons. I’ll be sure to tell my husband about this and that he should get the right type of metric fasteners for his little construction project.

Nice Blog Thanx For Sharing information we are Nishant Steel Industries is ISO certified leading Fasteners manufacturer of high tensile hot and cold forged fasteners made in India.