Importance of Fire Protection System

Fire Protection systems are a very important part of safety in any operating plant as it provides a reasonable degree of protection to expensive equipment, property, documents, life, and inventory during a fire event. For Oil & Gas, Refinery, or plants those deals with Petroleum or similar flammable products, It must have to be in place to avoid major loss during uneven circumstances.

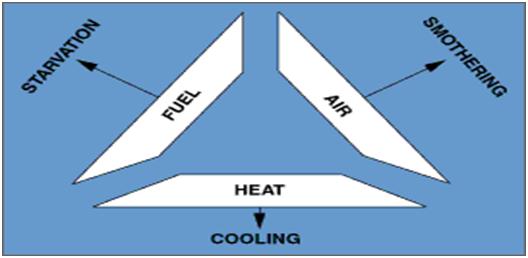

A Fire requires combustible materials, oxygen, and an energy source (heat) to provide ignition. Three components – fuel, oxygen & heat are referred to as the fire triangle.

Principle of Fire Extinction:

- Starvation – Removing or blanketing the fuel

- Smothering – Cutting off or diluting the oxygen supply

- Cooling – Removing heat from the fire.

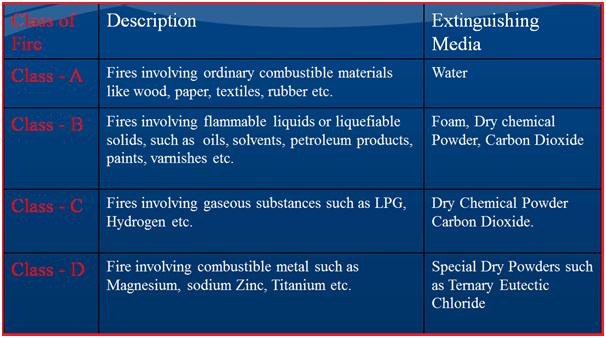

Types of Fire & Extinguishing Medium:

Fire Fighting Agents:

Fire Fighting Agents are those substances that are used to reduce the effect of fire during fire events. Examples are:

- Sand

- Blanketing

- Water

- Steam

- Carbon dioxide

- Dry Chemical Powder

- Aqueous Film Forming Foam (AFFF)

Properties of Petroleum Products:

- For all flammable liquids, it is the vapor that burns and not the liquid.

- Petroleum vapor is heavier than air so it has a tendency to descend on the ground or lower level or sump.

- Petroleum is immiscible with water. Its specific gravity is less than 1, so they float on water

- The electric conductivity of almost all petroleum products (except crude oil, ethanol, etc.) is very low and hence it generates static electricity during storage and transportation

Petroleum Products are divided into the following classes

- Class A – Flashpoint < 23 deg.C

- Class B – Flashpoint > 23 deg.C & < 65 deg.C

- Class C – Flash point > 65 deg.C & < 93 deg.C

- Unclassified – Flash point> 93 deg.C & above

Fire Protection Facilities in Petroleum Installations:

Codes and Standards for Fire Protection System Design

The following reference codes and Standards govern the design of Fire Protection System Design.

- NFPA 24 – Standard for the Installation of Private Fire Service Mains and Their Appurtenances

- NFPA 13 – Standard for the Installation of Sprinkler Systems

- NFPA 15 – Water Spray Fixed System

- NFPA 11 – Standard for Low, Medium, and High expansion foam

- NFPA 16 – Standard for the Installation of Foam water sprinkler and Foam water Spray system

- NFPA 20 – Standard for the Installation of Stationary Pumps for Fire Protection

- NFPA 22 – Standard for Water Tanks for Private Fire Protection

- NFPA 30 – Flammable and Combustible Liquids Code

- IP 19 – Fire Precautions at Petroleum Refineries and Bulk Storage installations

- DEP 80.47.10.31-Gen – Active fire protection systems and equipment for onshore facilities

Fire Protection System Design

- The firefighting system should be designed based on the Single Fire Scenario.

- The Facility should be divided into zones

- The type of Fire Fighting system should be decided.

- Fire-Water application rate and discharge time should be referred from IP-19 or NFPA standards.

- Firewater demand for the facility should be calculated.

- Similarly, the water required for the Foam system should be calculated.

- The facility with the highest water demand is considered critical and based on this the Firewater storage tank and pump capacity should be determined.

What are the different types of fire protection systems?

- Fire-Water Tanks: Above-ground storage tanks of adequate nos. to meet the norm of 2 hr. continuous firefighting (As per IP-19).

- Fire-Water Pumps

- Hydrant Network

- Water Spray System

- Foam Pourer System

Fire-Water Pumps

Fire-Water Pumps (Fig. 4) should be selected based on the largest firewater demand for the facility. Fire-Water Pumps should be selected as per NFPA requirements

Firewater pumps should be three basic types as a minimum:

- Electrical Driven Pumps – Primary Considered as cost-effective but not mandatory

- Diesel Driven pumps – Secondary considered but mandatory

- Jockey pumps – Required to keep the hydrant system pressurized and to check the health of the Fire Water system

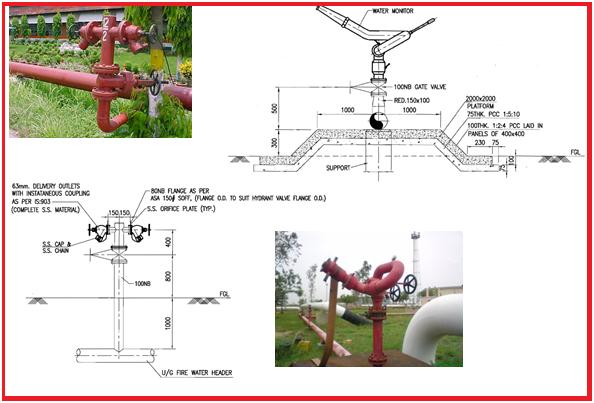

Hydrant Network in Fire Protection System

- Hydrant Networks (Fig. 5) consist of Hydrants and Monitors.

- Hydrants and Monitors should be placed at least 15 meters away from the hazard but not more than 45 meters.

- Proper coverage should be checked for the hydrant and monitors ensure the facility under protection is adequately covered.

- The hydrant mains can be laid above ground or underground.

- The hydrant mains should form a closed loop ensuring multi-directional flow in the system. The layout should be such that the facility has access to Fire protection at any given time.

- Isolation valves should be located at branches and other strategic locations.

Water Spray System as Fire Protection System

- The water spray system (Fig. 6) is provided for cooling the tank shell, and piping exposed to fire. The system is provided for cooling the structure on fire and exposure protection of adjacent property

- The system consists of fixed piping with pipe fittings, isolation valves, NRV, and water spray nozzles.

- In the case of tank and piping, the water spray directly impinges onto the surface of the tank or piping for cooling.

- A spray ring should be installed between each tank wind girder.

- NFPA 13 and NFPA 15 requirements should be met

- Two types: Manual Water Spray system and Automatic Water Spray system

Use of Foam Pourer System (Fig. 7) in Fire Protection:

- Semi-fixed foam Pourer system – Comprises fixed pipings and pipe fittings, drain valves, foam coupling, foam makers, foam pourer, and deflector plate on tank.

- Mobile Foam tender is required for actuating the system.

- Fixed foam pourer system( Manual/Automatic) – Manual system comprises of fixed foam concentrate storage shed, foam supply pumps, proportioning system, pipings, and pipe fittings, isolation valves, drain valves, foam coupling, foam makers, foam pourer and deflector plate on tank.

- The automatic system requires motor-operated valves at different points and PLC for its actuation based on feedback from the automatic fire detection and alarm system.

Extinguishing System for Fire Protection

- Fire Extinguisher – CO2, DCP, Clean Agent

- Clean Agent System – FM 200, Halon, etc.

- Sand Buckets

Some more References for you

Piping Design and Layout

Piping Stress Analysis

Piping Interface

Piping Materials

Piping Design Softwares

Hey I’m for the first time here. I found this board and I find

It really useful & it helped me out a lot. I hope to give something back and help others like you aided me.

I had no idea that these fire protection pumps were so huge! I guess they would have to be in order to get a high enough pressure to shoot water up into buildings. It’s really impressive to see the different designs of pumps.

Thoughtful ideas . I was fascinated by the specifics , Does anyone know if my business could possibly access a blank CA SOS Form SI-200 document to fill in ?

Is there any Surge Requirement for Fire water Rings?

Hi, your blog was really useful to understand the different types of fire protection systems.

It’s interesting to learn about how hydrant systems would help determine how to properly plan out a fire protection system. For the construction of my new home, I’d like to look for fire protection engineers that can help me out in determining that.

It is very useful for senior safety engineer, please share more information for safety & fifi design for oil & gas industry. thanks