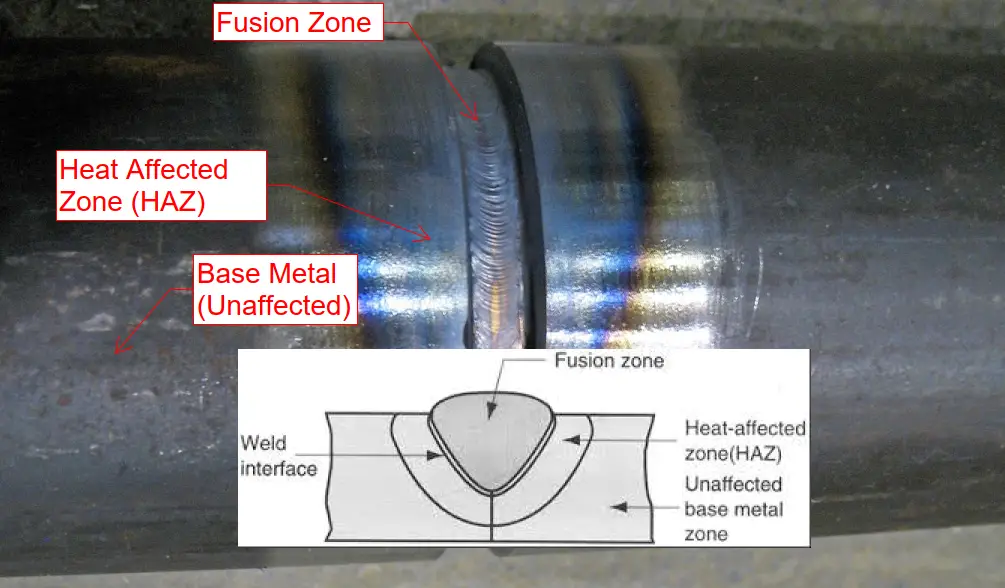

The heat-affected zone (HAZ) is an area generated when a metal is subjected to very high temperatures (Example: Welding, Mechanical Cutting, Laser Cutting, Plasma Cutting, etc). This is the non-melted zone near the exact worked area. The mechanical properties of the heat-affected zone are altered due to being exposed to high temperatures. So, the heat-affected zone or HAZ can be defined as the area between the melted metal and the base metal where microstructural changes occur. Refer to the Fig. 1 below:

As can be seen from the above figure, while welding four distinct zones are created. Fusion Zone or FZ, Weld Interface, Heat Affected Zone or HAZ, and Unaffected Base Metal Zone.

The Fusion zone is a mixture of molten metal and filler metal. Next, the narrow mushy zone consisting of partially melted metal is the weld interface. The next region that suffers a peak temperature below the melting point temperature creating microstructural changes is known as the heat-affected zone. The parameters that decide the extent of microstructural changes are

- Amount of heat input

- Maximum temperature reached

- Duration of elevated temperature, and

- the cooling rate

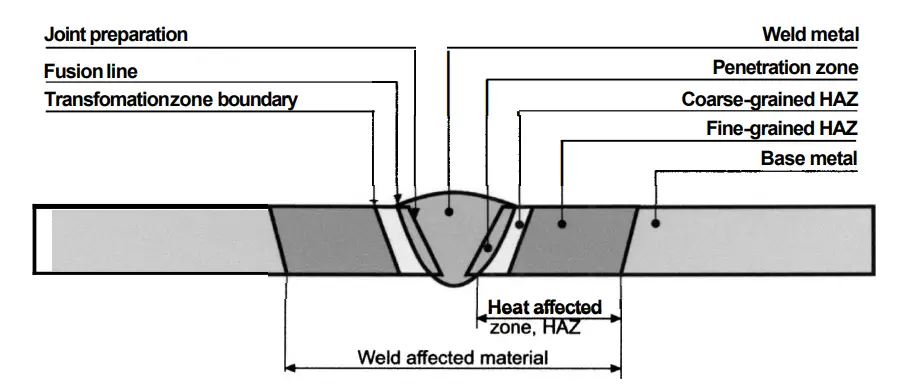

A heat-affected zone weakens the metal by reducing its mechanical strength and is the weakest section in a weldment. Depending on various factors like material properties, heat concentration, intensity, welding, or metal cutting process, the HAZ area can vary in size and severity. The nomenclature of zones and boundaries in the heat-affected zone is shown in Fig. 2.

Causes of Heat-Affected Zone

The amount of heat input during the welding or cutting process normally exceeds the melting temperature and subsequent cooling leads to microstructural changes. Thermal diffusivity is the single most important factor influencing the size of the heat-affected zone. The level of thermal diffusivity is dependent on the metals:

- the thermal conductivity

- density

- specific heat, and

- amount of heat input

Materials with high thermal diffusivity are capable of transferring the heat variation rapidly and cooling quicker, thus reducing the heat-affected zone width. On the contrary, materials with a lower thermal diffusivity coefficient retain the heat and the HAZ region becomes wider. Also, the duration of heat exposure has a direct impact on the HAZ region. When a metal is exposed to greater amounts of energy for longer periods the heat-affected zone is larger. With respect to the welding process the HAZ is dependent on:

- Heat Input: Low heat input will cool faster resulting in a smaller HAZ.

- Cooling Rate: Slower cooling rate will increase the size of the HAZ.

- Welding Speed: Faster welding speed will reduce the HAZ area.

- Welding Geometry: Weld geometry affects the heat sink. A smaller heat sink leads to slower cooling means larger HAZ.

In a similar way, the heat-affected zone for high-temperature cutting operations is also influenced by

- the temperatures during cutting

- speed of cutting operation.

- cutting process

- Shearing and waterjet cutting: No HAZ formation

- Laser cutting: A smaller HAZ

- Plasma cutting: An intermediate HAZ

- Oxyacetylene cutting: The widest HAZ

- the material properties, and thickness.

Effects of Heat-Affected Zones

Due to the heat experienced in the heat-affected zone, major undesirable microstructural changes occur that impacts the metal in various way as listed below:

- Lower Strength

- Residual Stress

- Lower toughness

- Reduced Corrosion Resistance

- Susceptibility to cracking

- Hydrogen embrittlement

- Phase Change

- Oxidation

- Surface Nitriding

- Localized Hardening

All these factors normally weaken the material creating challenges for the use of that material during the design of components.

Heat Affected Zone Area and Heat Tint Colors

During the welding or cutting, distinct HAZ areas are formed by the use of different temperatures in the base metal. A series of visible colored bands are generated known as heat tints. They are caused by the surface oxidation process specifically in stainless steel. However, these temperatures causing the ‘temper colors’ are much lower temperatures than those which form the heat-affected zone. Also, these color bands can extend for some distance beyond the actual heat-affected zone. These different colors vary from light yellow to dark blue and provide an approximate indication of the metal temperature reached. The following table provides the band colors with respect to temperatures:

| Color | Welding/Cutting temperature |

| Light yellow | 290º C |

| Straw yellow | 340º C |

| Yellow | 370º C |

| Brown | 390º C |

| Purple brown | 420º C |

| Dark purple | 450º C |

| Blue | 540º C |

| Dark blue | 600º C |

The parameters that affect the formation of these colored heat tints in the heat-affected zone are:

- The material’s resistance to oxidation

- Chromium content

- Surface Condition

- Extend of impurities on the surface

- Presence of surface paints, oils, fingerprints, etc.

However, note that these heat tints do not impact the extent of the heat-affected zone.

Reduction of HAZ formation

Reducing the effect of the heat-affected zone can alleviate problems like corrosion, cracks, embrittlement, etc. These will make the component much stronger. Ideally, by selecting proper welding and cutting operation, the heat-affected zone should be minimized. But it may not be always possible to reduce the HAZ to the extent required. Hence, various methods can be applied to reduce the heat-affected zone as mentioned below:

- Heat Treatment: Heat treatment is the best method to reduce the impacts of HAZ. Depending on the required mechanical/metallurgical properties and intended changes heat treatment process following the welding or cutting is selected. Based on the material a precipitation hardening and softening treatment can be applied.

- Cutting the Heat-Affected Zone: Sometimes, cutting and grinding can be used to reduce the HAZ area.

- Machining the HAZ: Machining to remove the heat-affected zone is also an effective method to reduce the impact.

- Colored Heat tints can be easily removed with fine sandpaper or by grinding.

Heat-Affected Zone Distance

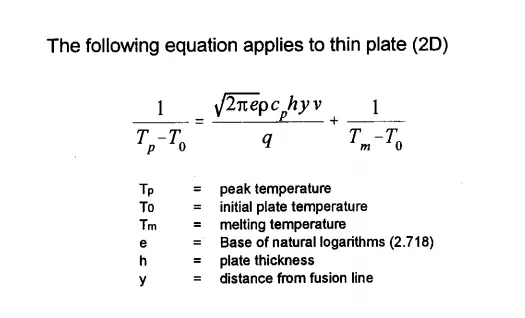

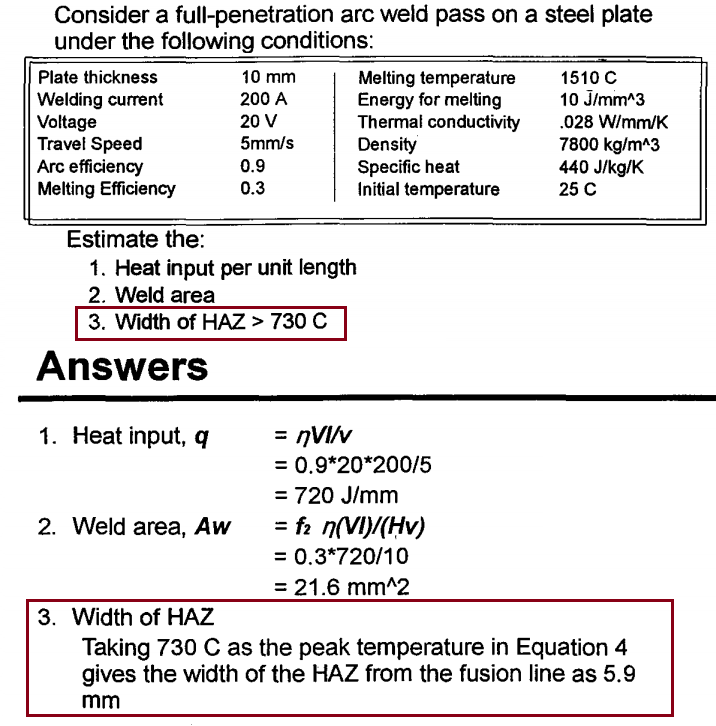

Calculation of heat-affected zone distance or width is not straightforward and very difficult. However, a simplified equation as provided in Fig. 3 below can be used for estimating HAZ distance/width for welding thin plates.

The above formula can be used to calculate the heat-affected zone distance. By knowing the peak temperature of the HAZ zone, the distance y can be calculated from the fusion line for welding a thin plate. Fig. 4 below provides a sample problem calculation regarding the same (Equation 4 mentioned in the answers is the equation shown in Fig. 3)

Thank you so much sir its really a great help..

Do you have reference(s) for the HAZ calculation provided?

what is the importance of HAZ in producing a crack free weld?