The factor of safety or safety factor is a very important term in engineering design. While designing any Engineering product or component, safety is of utmost importance. To ensure the safety of those items, each component is designed to bear more loads than its actual operating loads. So, there will always be some margin or cushion as compared to its operating capabilities. This is ensured during the design stage by considering a suitable factor of safety. In this article, we will discuss the following:

- What is the Factor of Safety?

- Importance of Factor of Safety in Engineering Design

- Factors Affecting the Factor of Safety

- Equation of Factor of Safety

- Examples of Factors of Safety, and

- Many More…

What is the Factor of Safety?

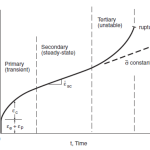

The factor of safety is defined as the ratio of the ultimate stress of the component material to the working stress. It denotes the additional strength of the component than the required strength. Factor of Safety is also popular by its abbreviated form FoS or FS. It is a numerical value that quantifies the safety level and reliability in engineering design. So, the factor of safety provides a buffer zone for engineers to ensure that their design will not fail under certain extreme conditions.

Importance of Factor of Safety

A factor of safety is related to the safety of people. It reduces the risk of failure of a component by adding some cushion in the design. Also, there always will be some hidden circumstances or unknown parameters that can not be considered accurate in design. At the same time, the reliability of the material is not 100% and the load used in design calculation is not the maximum load. So the factor of safety or safety factor provides protection against those unknown events to some extent.

Although all components are designed with a factor of safety, it’s always suggested to use those components within their design limit.

Factors Affecting Determination of Factor of safety

Component design codes & standards normally provide a minimum factor of safety for that component. However, choosing the exact safety factor is dependent on various parameters like

- Material type Ductile vs. Brittle

- Loading type Static vs. dynamic

- Whether cyclical loads

- The intensity of stress concentration

- Unforeseen Misuse of the component

- Accuracy and stress complexity during a calculation, Reliability of Data used in the factor of safety calculation.

- Environment and design temperature and pressure.

- Impact of failure

- Cost of component or material

- Corrosion rate

- Maintenance frequency

- Application of the component

- Industry Standards and Regulations

- Historical Data and Experience

- Design Optimization

- Client or Stakeholder Requirements

Factor of Safety Equation | Formula for Factor of Safety

As defined in the first paragraph, the factor of safety is a ratio of two loads or two stresses. Mathematically factor of safety can be expressed as

Factor of safety=Ultimate Load (Strength)/Allowable Load (Stress)

As understood from the above equation the allowable stress is always less than the ultimate failure stress. Hence, the factor of safety is always greater than 1. The ultimate stress for brittle material is considered as ultimate tensile strength and for ductile material is considered as yield strength.

Also, as the equation for the factor of safety is the ratio of two stress or load values, it is dimensionless. The difference between the Factor of Safety and 1 is known as the Margin of Safety. So,

The margin of safety = (Factor of safety-1).

Examples of Factors of Safety

Typical examples of the factor of safety for some materials depending on application and loading types are listed below in Table 1. However, please note that the table only provides a typical range or typical values to provide an example. Actual values for the factor of safety must be taken from the design standard of the relevant component. For example, the factor of safety for pressure vessel design must be taken from the ASME Sec VIII code.

| Sr No | Member | Typical Factors of safety range |

| 1 | Structural Members in building services | 2 |

| 2 | Pressure Vessel | 3.5 to 4 |

| 3 | Automobiles | 3 |

| 4 | Aircraft and Spacecraft | 1.2 to 3.0 |

| 5 | Aircraft components | 1.5 to 2.5 |

| 6 | Boilers | 3.5 to 6 |

| 7 | Bolts | 8.5 |

| 8 | Cast-iron wheels | 20 |

| 9 | Engine components | 6.0 to 8.0 |

| 10 | Heavy duty shafting | 10.0 to 12.0 |

| 11 | Lifting equipment – hooks | 8.0 to 9.0 |

| 12 | Pressure vessels | 3.5 – 6 |

| 13 | Turbine components – static | 6.0 to 8.0 |

| 14 | Turbine components – rotating | 2.0 to 3.0 |

| 15 | Spring, large heavy-duty | 4.5 |

| 16 | Structural steelwork in buildings | 4.0 to 6.0 |

| 17 | Structural steelwork in bridges | 5.0 to 7.0 |

| 18 | Wire ropes | 8.0 to 9.0 |

| 19 | Highly reliable materials where loading and environmental conditions are not severe | 1.3 to 1.5 |

| 20 | Moderately reliable materials where loading and environmental conditions are not severe | 1.5 to 2 |

| 21 | Ordinary materials where loading and environmental conditions are not severe | 2 to 2.5 |

| 22 | For use with less tried and for brittle materials where loading and average environmental | 2.5 to 3 |

| 23 | For use with materials where properties are not reliable and where loading and environmental conditions are not severe, or where reliable materials are used under difficult and environmental conditions | 3.0 to 4.0 |

| 24 | Impact Forces | 3.0 to 6.0 |

| 25 | Brittle Material | 1.0 to 6.0 |

Factor of Safety Calculator

Various factor of safety calculators are available online to calculate the values of the factor of safety with known ultimate strength and allowable stress values. Let’s take an example to calculate the factor of safety for the following situation:

The yield strength of a ductile material is 240 MPa. If the material is subjected to a loading condition that generates the maximum allowable stress of 140 MPa. Then the factor of safety of that material is 240/140=1.7. However, note that both stress values are in the consistent unit before calculating the factor of safety.

Note that with an increase in the factor of safety, the safety level increases. But, the design cost also increases at the same time. So, engineering judgment must be made following industry codes and guidelines to consider a proper factor of safety.

Very handy concise information

Excelent information……thanks…

Thanks for this information

thanks.it’s really useful

thank you so much for this info

im a year 3 college student and this has helped a lot

Helpful information, keep up the good work my friend…

Hi my friend

Excellent work, what is your recommendation for safety factors for calculating strength in facilities for a person such as a leg prosthesis

It’s and comes with easy understanding as well.Thanks very much Mr