Common questions asked in Piping stress interviews related to Jacketed piping are listed below:

1. Why is Jacketed Piping used?

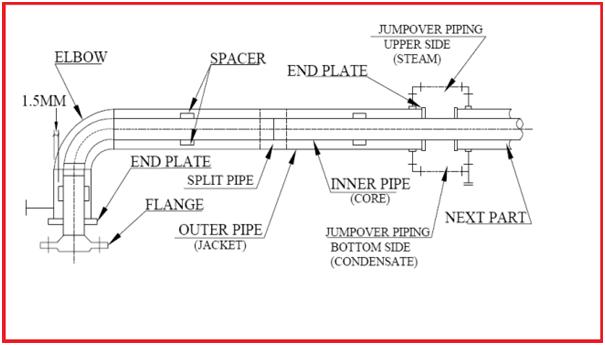

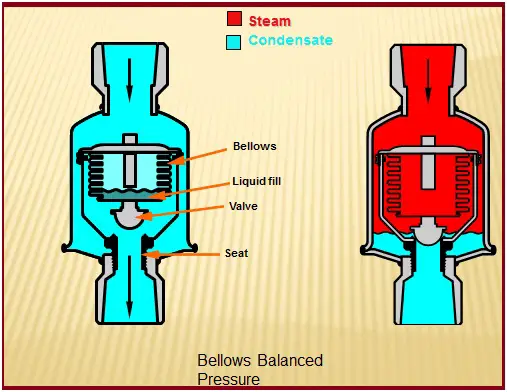

Ans: It is commonly used to convey very viscous process fluids in an inner pipe, heated by steam/hot water/hot oil or other heating media between the jacket and core pipe. Vacuum jacketing is also used as an insulator for cryogenic fluids and can be analyzed using the same calculation method for heated jacketed piping.

2. If water (density=1000Kg/m3) is flowing through the jacket then what is the value of density you will enter into the Caesar spreadsheet?

Ans: We have to calculate the equivalent density for the same. The following formula can be used

Actual jacket fluid equivalent density = [(rj2 – Rc2)/ rj2 ] x dj

Where,

- rj = Inner radius of core Rc = Outer radius of pipe

- dj = Density of heating medium

3. What are the major stress checks that you will perform while analyzing the Jacketed Piping system?

Ans:

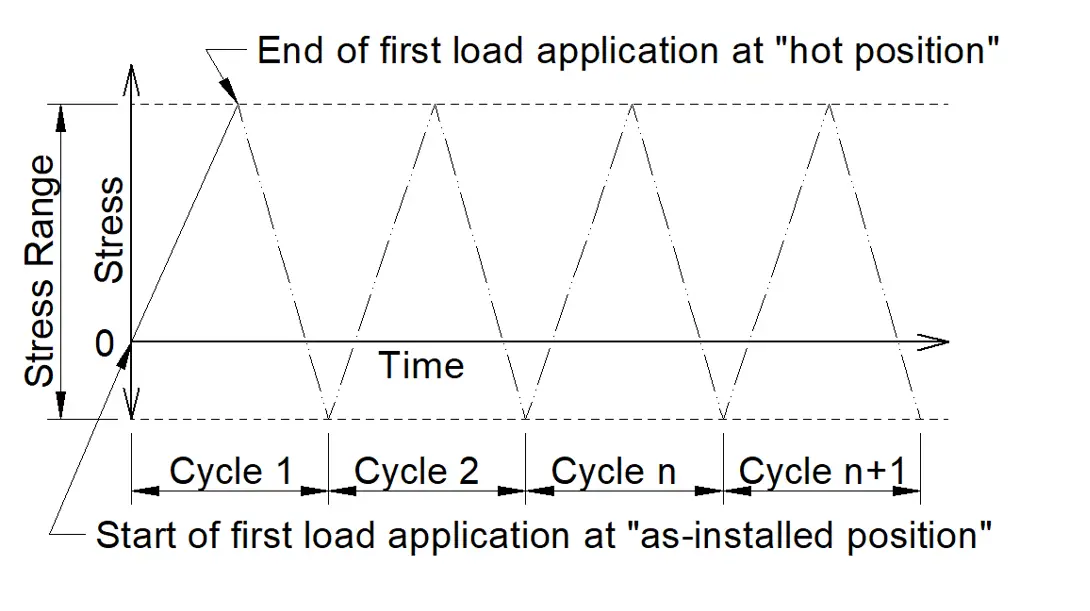

Sustained And Expansion Stress Check: Limits of calculated stresses due to sustained loads (primary stresses) and displacement strain due to expansion (secondary stresses) should be evaluated separately for core and jacket pipe (as per clause 302.3.5 of ASME B31.3).

Checking of the buckling load. (Manual Calculation): This check will not be performed by Caesar-II as it is not in the code. However, it will provide force calculated at the junction point (P) between the core and the jacket. It should be less than Pcr which is given by the formula

- Pcr = (4π2 *Ec*Ic)/L2, For Core and

- Pcr = (4π2 *Ej*Ij)/L2 , For Jacket

Where,

- P = Force calculated by a computer program at the junction point

- Pcr = Critical force

- Ec, Ej = Modulus of Elasticity of core/ jacket material

- Ic = Moment of Inertia of Core

- Ij = Moment of Inertia of Jacket

- L = length of pipe between the junction of the core/ jacket.

If P ≤ Pcr then no buckling failure ·

Weld strength check between the jacket and core pipe: P calculated at the junction point between core & jacket pipe compared with allowable load at the weld point.

- P allowed = area of weld * 80% of hot allowable stress of the material

- Area of weld = π D * root of the weld

- D = Diameter of the core pipe

- The root of weld = 0.707 * weld size

- If P calculated ≤P allowed, then the system is safe ·

Checking of deflection of jacket: In this case, it is assumed that no spider/spacer is used between the core and jacket. The deflection for the jacket with available length has to be computed and should be ensured that it does not create an obstruction to the flow of hot medium in the jacket. Normally maximum allowed deflection of the jacket is T/2, where T is the thickness of the jacket.

Checking for External Pressure (By material Group): Sometimes the jacket may be subjected to partial vacuum conditions due to failure of the steam supply and subsequent condensation of steam inside the jacket. In such cases, the jacket should be checked for vacuum conditions. As another example, in a system, the core is at a pressure of 30 PSIG and the jacket is at a pressure of 180 psig, then the core is subjected to an external pressure of 150 PSIG. For this, the core must be investigated for collapse or local buckling from the external pressure load (Refer para 304.1.3 of ASME B31.3 and UG-28 through UG-30 of ASME BPVC Section-VIII Division-I) ·

Checking for Axial Stress: As per ASME B31.3, the calculated displacement stress range (Expansion case stress) is SE = (Sb2 + 4St2)1/2. The code does not take into account the axial forces and consequent axial stress in calculating expansion stresses. This is because for the normal pipe axial forces are normally due to longitudinal stresses which are already taken care of in thickness calculation and sustained stress calculations, but in the case of jacketed piping, axial stresses at the core-jacket junction point are just not due to longitudinal stresses, but mainly due to differential thermal expansion of core and jacket pipes. Thus calculated stress should be corrected by adding axial stresses for local analysis of that particular junction point. Thus,

Actual Stress SEa = SE + Axial Force/ Area Axial force can be obtained from CAESAR output or can be calculated by the equation,

Faxial = (E x ΔL x Area) / L

Or else, CAESAR also calculates the value of axial stresses which it calculates for operating cases. Activate the option “Add F/A in stress” in the configuration file. Axial stress due to thermal differential is added to the calculated expansion stress and then it should be compared with the allowable loads as per ASME B31.3.

4. What allowable value is considered for welding check at core jacket interconnection?

Ans: Two methods are prevalent. You have to consider any one of the following (discuss with the stress lead) a) Consider the 0.6 times electrode tensile strength (As per AISC code) b) Consider SE=1.25Sc+0.25Sh of the electrode as allowable (as per secondary stress generated theory)

Hi,

For jacketed pipe stress analysis, how to check the nozzle l

Dear Sir,

How model jacketed pipe in caesar ii.

Soon I will post an article on modelling of jacketed piping…

Sir I want to ask you a modelling approach for jacket pipe at termination point of connecting equipment.

1.Can we anchor core or jacket pipe(Any one) and connect both by using C-Node?

2.Mention two different anchors in both core and jacket and mention c node in any one of them?

3.mention 2 different anchors of both core and jacket and one more anchor with c-node mentioned?

Please clarify.

Hi Anup,

Have you worked on stress analysis ControTrace piping? Any thoughts or input as to how was it modelled in CII?

Sir:

good day,

about the equivalent density formula, the denominator “r^2” should be corrected to “R^2”. Am I right?

De=[(R^2-r^2)/R^2]*d

I think there is a mistake in terms entered ,

Given :-

rj = Inner radius of core

Rc = Outer radius of pipe

Actual:-

rj = Inner radius of jacket pipe,

Rc = Outer radius of core pipe

You are right

description of parameters of Formula is wrong