Inch Dia and Inch Meter are the terms frequently used in the piping construction industry. Both Inch-dia and inch-meter are units for measuring the quantum of piping construction jobs for fabrication, erection, and hydro test purposes. Inch-Dia is also known as Dia-Inch or abbreviated DI in some organizations. Similarly, the Inch-Meter is denoted by the acronym IM. In this article, we will explore the significance of Inch Dia and Inch Meter and their calculations with examples.

What is Inch Dia?

Piping Inch-dia and Inch-meter are used during the construction of chemical, petrochemical, fertilizer, refinery, power, and oil&gas industries. The progress of piping spool fabrication mainly welding is measured by the term Inch Dia, which is a short form of Inch-Diameter.

In piping welding, the pipe size is converted to the equivalent inch-dia and reported.

Example and Equation for Inch-Dia Calculation

Let’s understand the calculation of inch diameter with some examples,

Assume a 6″ NPS pipe of length 60 m needs to be produced. We all know that pipes are not manufactured with indefinite lengths. Single random length pipes are manufactured in the length of 5 to 7 m whereas double random length has a length in the range of 11 to 13 m. So to make a pipe of length 60 m we have to weld smaller length pipes. So even if we consider a maximum length of 13 m, there will be a minimum of 4 welding joint requirements. This pipe welding requirement is denoted by Inch dia.

As per the above example, the Total required inch dia=Diameter of pipe in inches X No of joints required =6 X 4=24 inch dia.

Similarly, if the pipe NPS is 12 inches and the required number of joints is 6 then the inch dia will be 12 X 5=60 inch dia. The joints with Pipe Spool, Elbow, Tee, Reducer, Flanges, Valves, or other piping components are denoted and calculated using Inch-Dia in a similar way.

So, the equation for inch dia calculation can be represented as below:

Inch Dia=Pipe Size in Inches X Total Number of Joints for that size.

Other than welding, NDT tests like radiography and DPT requirements are also measured in terms of Inch Dia. The payment for all these construction activities is calculated based on Inch-Dia.

What is an Inch Meter?

An Inch Meter is specifically used to measure the progress of Piping erection and hydro-testing. The pipe length that is erected or hydro-tested at the construction site is converted to the equivalent Inch Meter of erection or hydro testing.

Example and Formula for Inch-Meter Calculation

The equation for calculating Inch-Meter is

Inch Meter=Pipe NPS in Inches X Length of Pipe in Meters

Let’s understand the concept of the Inch-Meter Calculation with some examples,

Assume a 20-inch NPS pipe of 100 meters in length is to be erected at the site. So, the quantum of the piping erection job is 20 X 100= 2000 Inch-Meter.

Similarly, If a 12-inch pipe of 50 m length is required to be hydro-tested the quantum of piping hydro-testing job is 12 X 50=600 Inch-meter.

All piping erection jobs, insulation, etc. are converted to Inch-meters for measuring progress for payment purposes.

The estimated inch-dia and inch-meter also help to calculate the required number of professionals and associated cost and time requirements for any project.

Sample Calculation of Inch-Dia

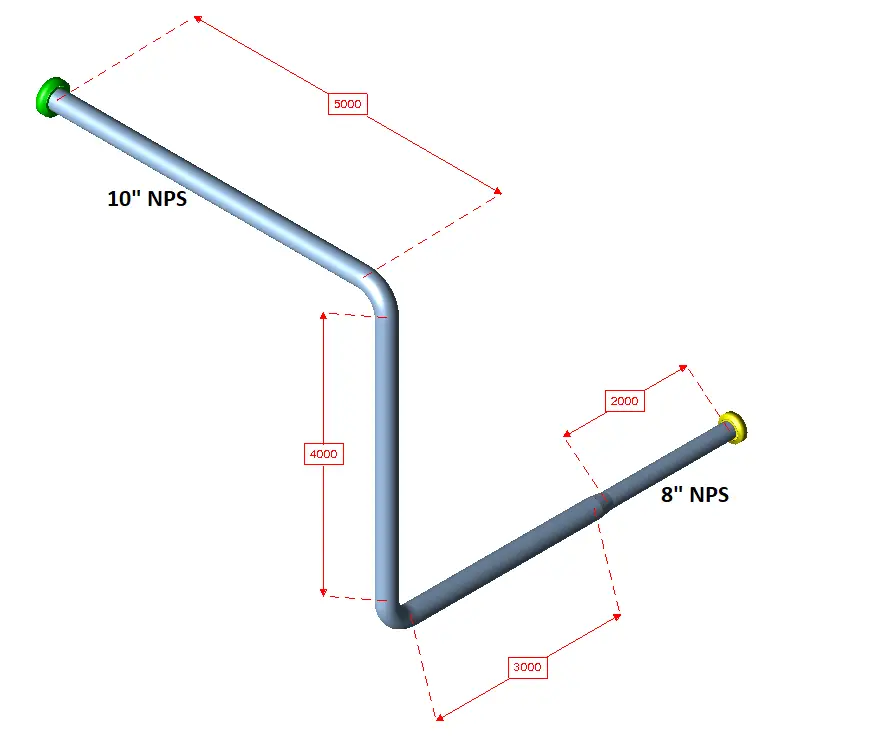

Let’s calculate the Inch dia for the configuration shown in Fig. 1.

In this diagram, the size of the larger pipe is 10 inches NPS and the total number of joints in the 10-inch pipe is 6 (1 with the flange, 4 with the elbows, and one with the reducer). So, the Inch dia for the 10-inch line is 10X6=60 inch-dia.

Now the diameter of the smaller pipe is 8 inches NPS.

The total number of joints in the 8-inch pipe is 2 (1 with the flange and the other with the reducer).

So, the Inch-dia for the 8-inch pipe = 8 X 2=16 inch dia.

Hence, the total calculated inch-dia=60+16=76 inch-dia

Significance of Inch-Dia and Inch-Meter Concept in Piping

In the piping industry, the inch meter and inch diameter concept is used for various purposes:

- To find out the piping erection load

- Proper manpower planning and estimation

- Piping work progress reviewing and monitoring, and

- Cost estimation and budget planning

Difference of Inch-Dia and Inch-Meter Calculation in Unit Piping and Rack Piping

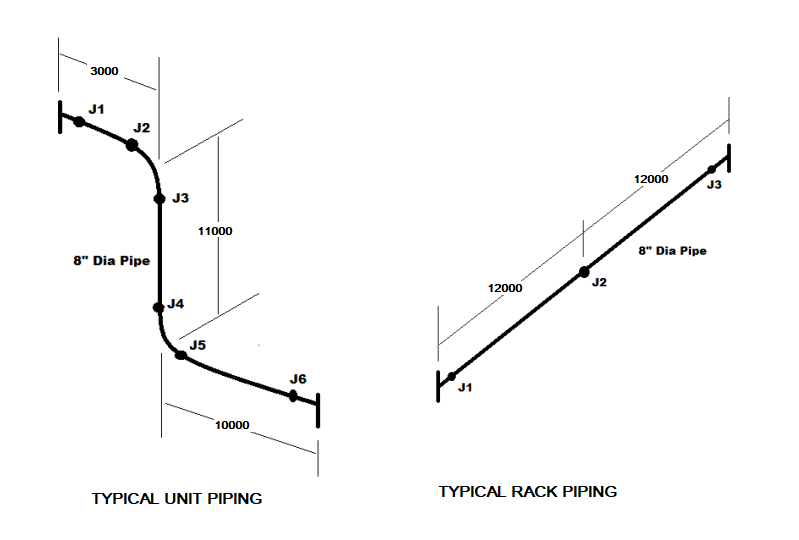

In the usual unit piping, two pieces of equipment are connected using the piping work in the process and utility areas. As the piping in such areas is usually complex, more joints are required with respect to total pipe length. On the other hand, in rack piping or cross-country piping (/pipeline), the pipework connection is usually straight which requires less number of joints. So, the inch diameter requirement for complex unit piping jobs is more as compared to usual rack piping. Let’s take an example to understand this concept.

In the above figure (Fig. 2), the dia-inch for the unit piping is 6 X 8 =48 inch-dia (6 joints in 8 inch diameter pipe; J1, J2,…., J6 denotes joints) whereas the same for the rack piping is 3 X 8= 24 inch-dia (as only 3 joints) even though the inch-meter for both the piping configuration=24 X 8=192 Inch-Meter.

The Inch-Diameter in piping is basically a unit of measurement for fabrication and inspection processes like welding, Dye Penetration Inspection, Radiographic Testing, etc. for a basis of payment. On the other hand, the inch-meter in piping defines the job quantum for piping erection, piping insulation, etc., and estimates related payments to sub-contractors.

I am science background I am faceing drawing study problem I how to improve my knowledge to study on drawings

Hi, I have a question, does it apply the same formula for sockolet to find dia inch?

Yes, But this time Dia. of sock-o-let will be considered.

hi, how to determine the labour cost (labour + consumables) for each dia inch and inch meter? is there a market norm? or you can share some rate example (both Carbon steel and stainless steel)

Thank you very much

This really helps. Thanks Anup

How to estimate in dia inches, considering joints and length of a pipe given on isometric?

Thank you,

Thank you sir

good idea, go forward

If 30″ pipeline construction cost is Rs.12000/meter then what is the cost construction for Inch-Dia and Inch-M

Sir, do you have a formula to calculate cost erection for inch-m?

kindly let us know how to measure fittings, valve, bends, reducers etc. in the piping works.

what does unit of measurement PMD mean? is it per meter dia and if yes, how is it is calculated.

Your content was useful and informative, thank you