While dealing with valves, you must have come across the abbreviations LO and LC. In valve terminologies, LO stands for Locked open and LC is an abbreviation of Locked Closed. Both LO and LC can imply various types of valves like Ball Valves, Butterfly Valves, Globe Valves, or others depending on the application. In this article, we will learn the meaning of LO and LC with respect to valves.

The use of the terms LO and LC in valves are often correlated with the health of the system. It ensures the valve works during normal operation. The requirements of LO and LC during the design phase are essential in maintaining the safety and integrity of the system.

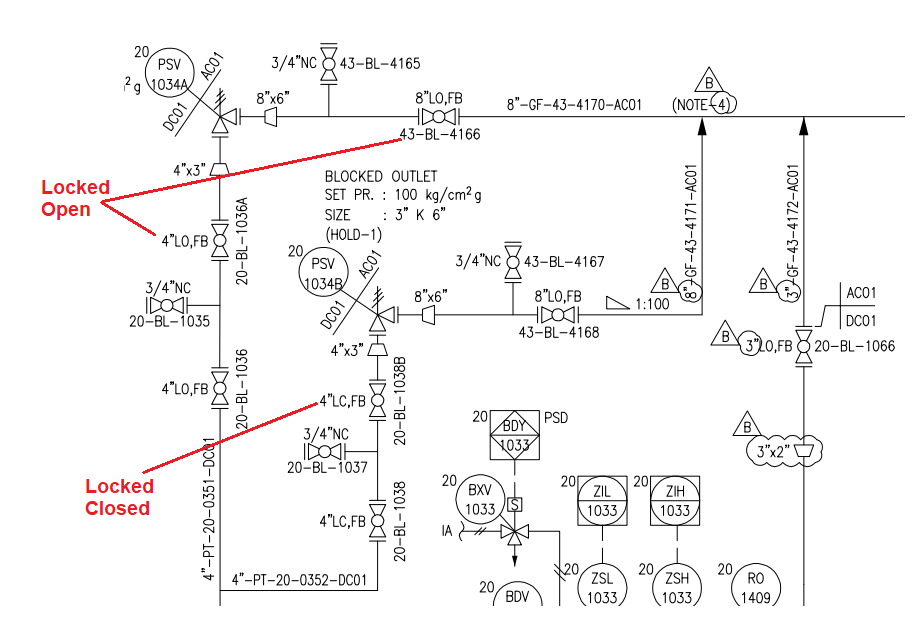

Control valves are generally specified to add a locking arrangement as part of the vendor supply. It can be cleat located on the valve body or a plate by drilling a hole in the valve. Process P&IDs must identify such requirements (Refer to Fig. 1) specified in the documentation by mentioning the terms LO and LC as applicable. This locked open and locked closed method ensures there will not be accidental valve operation that enhances system safety. Only the designated responsible professionals can change the valve function from open to close or vice versa.

Refer to the above figure which shows how the LO and LC valve arrangements are specified in a P&ID. In the above image, it shows as out of two PSVs, the inlet valve of one PSV is kept in LO condition and the other is kept in LC condition. Both the valves in the PSV outlet line are kept in LO condition. In a similar way, LC and LO valve arrangements will be specifically designated in the P&ID drawing.

Locked Open (LO) Valves

Locked open valves are a type of isolation valve. A typical example of a locked open valve can be a pressure safety valve mounted on a pressure vessel. The locked open arrangement in this PSV will ensure the release of pressure during an overpressure event, thereby protecting the equipment. Accidental closing can be detrimental in such a scenario and this is because the locked open valve arrangement is usually established to keep the valves in open position throughout the normal operation.

Locked Closed (LC) Valves

A locked closed valve arrangement is chosen when the valve is to be kept in the closed position during normal working conditions. A typical example of a Locked Closed (LC) valve could be the closed drain system for maintenance. Throughout normal operating conditions, the entry of hydrocarbon must be avoided and this is because a locked closed valve arrangement should be chosen.

Note that, the locked open or closed status must be properly registered in the appropriate log. Also, the LO and LC status should be audited to ensure the proper working arrangement. To change any status for LO to LC or vice versa, a proper permit-to-work system must be followed.

The locking philosophy usually consists of an integral lock with a key arrangement. The keys are generally kept in the control room and only the authorized person can have the access to those keys. Sometimes, the valve with locked open or locked closed operation is performed in a sequential manner. A typical example is the PIG launcher and receiver where the sequence locking procedure is applied. The Pig launcher and receiver system have a number of valves and a separate designated key is assigned for all those valves.