A mechanical datasheet is a document that provides technical specifications and information about the mechanical aspects of a product or device. It typically includes information on dimensions, weight, materials, tolerance, temperature range, operating conditions, mechanical strength, and durability, among other things. The purpose of a mechanical datasheet is to provide engineers, designers, and manufacturers with the information they need to properly design, manufacture, and use the product.

A Mechanical Datasheet or MDS in short form is a basis for equipment procurement and fabrication by a vendor or manufacturer. The main responsibility for developing a mechanical datasheet lies with the mechanical engineer of that project. The main basis (input) of mechanical datasheet generation is a process datasheet from the process engineer. The involved Mechanical Engineer uses the process datasheet and further adds mechanical details like the equipment size and associated detail information for each equipment item, and provides a detailed sized equipment list for other engineering disciplines to complete their detailed engineering and design.

The Mechanical Datasheet (MDS) is the first step in the designing and procurement process of any equipment. The MDS is always accompanied by a Specification with a detailed description of the equipment, technological role, environmental characteristics, etc.

Items Requiring Mechanical datasheet

A mechanical datasheet can be generated for a variety of mechanical equipment, including:

- All static and rotating mechanical pieces of equipment in the project like pumps, tanks, compressors, pressure vessels, reactors, turbines, exchangers, etc.

- Mechanical components, such as gears, bearings, shafts, and springs

- Mechanical assemblies, such as engines, transmissions, and pumps

- Mechanical systems, such as HVAC systems and piping systems

- Mechanical devices, such as valves, actuators, and fasteners

- Consumer products, such as appliances, tools, and toys

- Industrial equipment, such as cranes, hoists, and conveyors

- Aerospace and defense equipment, such as aircraft, missiles, and military vehicles

- Medical equipment, such as prosthetics, implants, and surgical instruments.

In general, any type of mechanical equipment that requires precise specifications and information can benefit from a mechanical datasheet.

Equipment Datasheet in Oil and Gas

An equipment datasheet is a mechanical datasheet for any equipment. In the oil and gas industry, an equipment datasheet is a document that provides technical specifications and information about a specific piece of equipment used in the production, processing, or transportation of oil and gas. It typically includes information on the equipment’s dimensions, weight, materials, temperature range, pressure range, operating conditions, and any other relevant specifications that are critical for its safe and efficient operation. The purpose of an equipment datasheet is to provide detailed information to engineers, operators, and maintenance personnel, enabling them to properly design, install, and maintain the equipment. Equipment datasheets are commonly used for a wide range of oil and gas equipment, including pumps, valves, compressors, heat exchangers, pipelines, and storage tanks.

Advantages of Mechanical Datasheets

A mechanical datasheet provides several advantages, including:

- Improved design: A mechanical datasheet provides critical specifications that engineers need to design components and systems that will be compatible with the equipment.

- Enhanced manufacturing: The detailed information in a mechanical datasheet can help manufacturers produce the equipment to the required specifications, reducing the risk of errors and defects.

- Better performance: By specifying operating conditions, temperature range, and other critical parameters, a mechanical datasheet can help ensure the equipment operates efficiently and safely.

- Reduced risk: By providing accurate specifications, a mechanical datasheet reduces the risk of equipment failure and ensures that the equipment is used in a safe and appropriate manner.

- Efficient maintenance: The information in a mechanical datasheet can help maintenance personnel diagnose and fix problems more efficiently, reducing downtime and maintenance costs.

- Improved documentation: A mechanical datasheet provides a comprehensive and easily accessible source of information that can be used for reference, troubleshooting, and regulatory compliance.

Overall, the use of a mechanical datasheet can lead to improved quality, safety, and efficiency in the design, manufacture, and operation of mechanical equipment.

Examples of Mechanical Datasheets

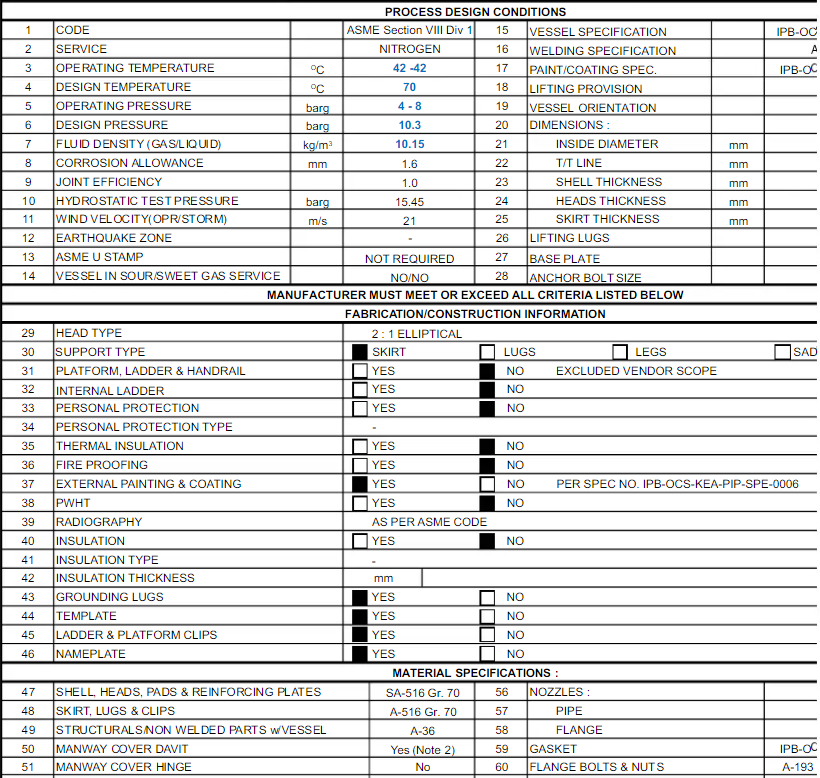

The image in Fig 1 shows parts of a typical example mechanical datasheet for a nitrogen receiver. In a similar way, mechanical datasheets of each piece of equipment and mechanical items may be generated by the mechanical engineer.

Process Datasheet vs Mechanical Datasheet: Difference between a Process Datasheet and Mechanical Datasheet

A mechanical datasheet and a process datasheet are both documents used to provide technical information about equipment, but they have different focuses and purposes.

A mechanical datasheet provides technical specifications and information about the mechanical aspects of a product or device, such as its dimensions, weight, materials, tolerance, temperature range, operating conditions, and mechanical strength. Its focus is on the physical characteristics and capabilities of the equipment.

A process datasheet, on the other hand, provides information about the process or application in which the equipment will be used. It typically includes information on process conditions, fluid properties, flow rates, temperatures, pressures, and chemical composition, as well as performance requirements and safety considerations. Its focus is on how the equipment will be used in a specific process and what conditions it will need to operate under.

The process datasheet of any specific equipment is the input for generating the mechanical datasheet for that specific equipment.

In summary, a mechanical datasheet provides information about the equipment itself, while a process datasheet provides information about how the equipment will be used in a specific process. Both documents are important for ensuring that the equipment is used safely, efficiently, and effectively.

Thanks for the information. It’s comprehensive too.

Please, i will like to have samples of Mechanical datasheets for mobile crane equipment.