In the process or the power piping industry, many a time several non-standard valves are used for some specific requirements. A few examples of those are Angular Valves, Three-Way valves, Four-way valves, valves with heavy Actuators, etc. This need to be modeled properly to get the actual effect is stress analysis. this article will briefly discuss the modeling of such valves.

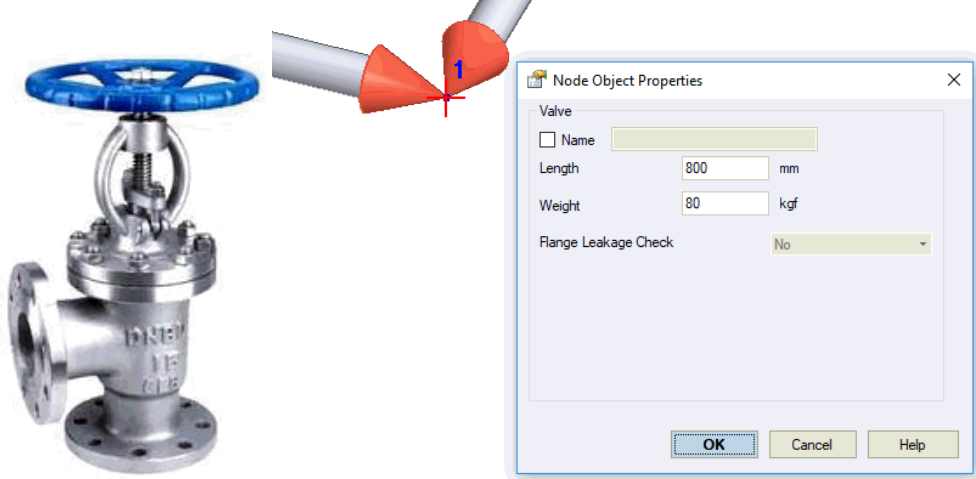

Angular Valve With Equal Legs

If the angular valve has equal legs, then it can be modeled using an ordinary valve element. Just put it into a node between two pipes. Pipes can have a different diameter. One half of valve length will be placed through the first pipe direction and one half through another.

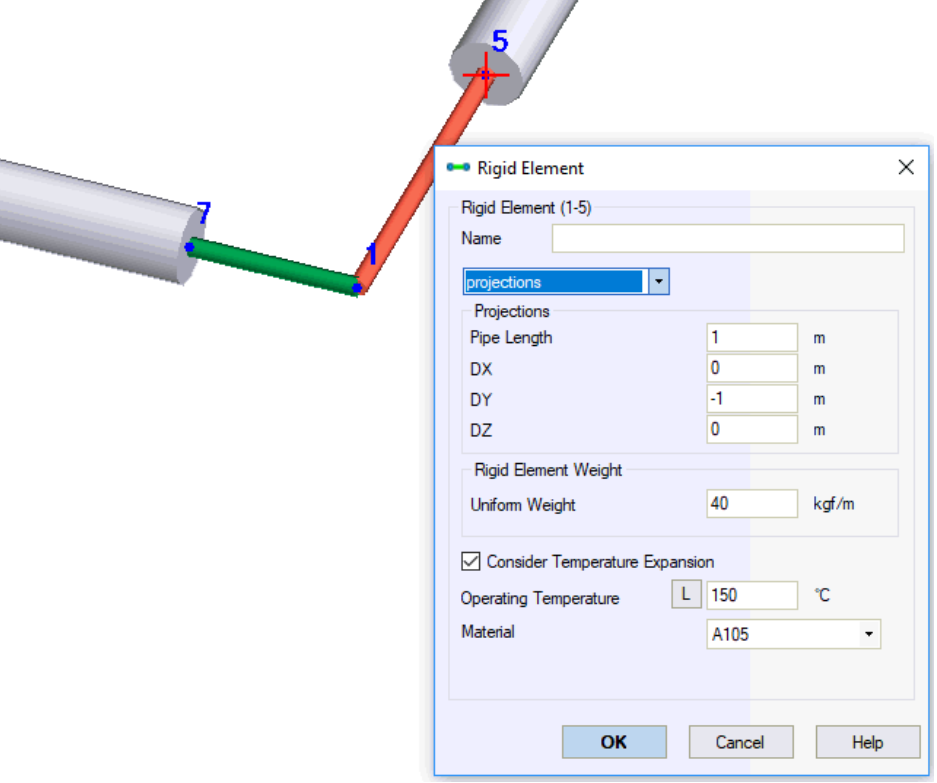

Angular Valve With Unequal Legs

If the valve has unequal leg lengths, then it can be modeled using rigid elements. The total weight of rigid elements should be equal to the valve weight. To model temperature expansion the temperature and material should be specified in a rigid element. Also, flanges can be added into end nodes of the valve to check leakage.

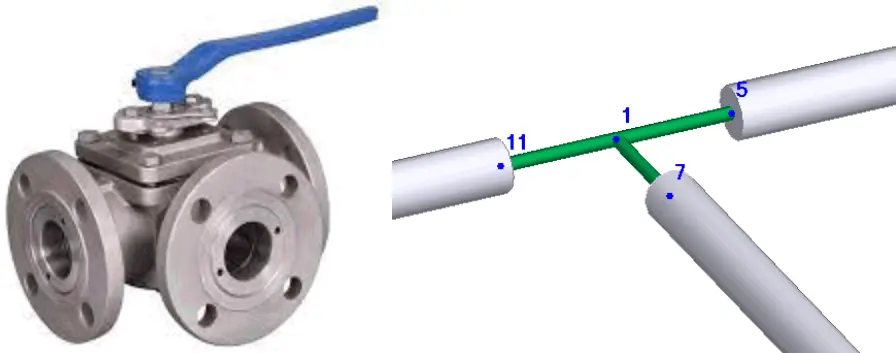

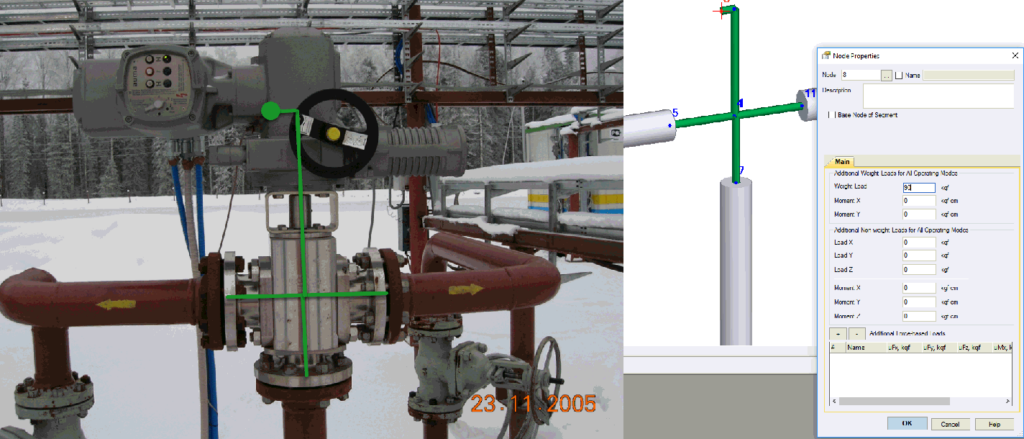

Three-Way Valve

The three-way valve can be modeled just using 3 rigid elements. The total weight of rigid elements should be equal to the valve weight.

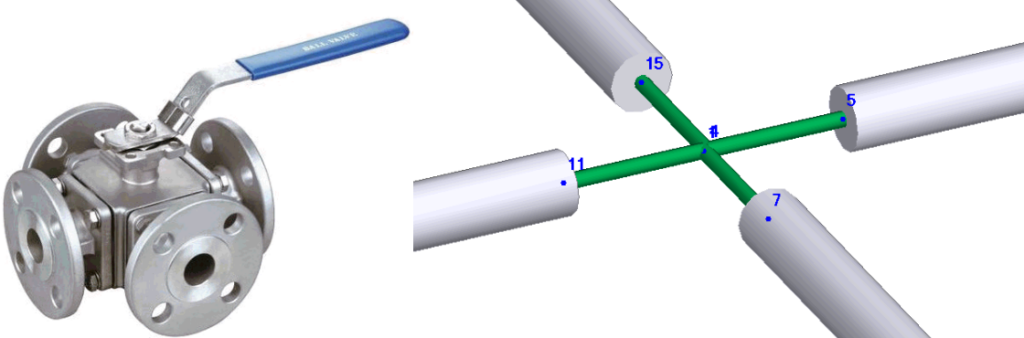

Four-Way Valve

In START-PROF four-way valve can be modeled using 4 rigid elements. The total weight of rigid elements should be equal to the valve weight.

Valve with Heavy Wheel, Actuator or Actuator Modeling

In START-PROF the heavy wheel or actuator can be modeled as node weight load at the actuator center of gravity. This mass should be connected to the valve using rigid elements with zero weight to consider eccentricity. Proper modeling of actuator eccentricity is especially important for seismic analysis of piping systems because the eccentric mass will produce a great additional torsion and bending moments on the piping system.

Just stretching the above discussion, how flanges will be added to rigid elements.

Please help!

Flanges can be added to valve length. Just increase the length of rigid elements

Or add flange element https://www.passuite.com/kbase/doc/start/WebHelp_en/index.htm#t=flange.htm