Pressure Equipment Directive or PED 2014/68/EU is a legislative framework at the European level for pressure equipment presenting pressure hazards applicable to the design and fabrication of pressure equipment. This directive has been made effective throughout the EU region from 19th July 2016 onwards. As per the pressure equipment directive, any equipment (Pressure vessels, Steam boilers, Piping, Assemblies, Safety Accessories, Pressure Accessories, etc) with more than 0ne liter in volume and pressure more than 0.5 bar gauge (or 7.25 PSIG) is termed as pressure equipment. The earlier directive 97/23/EC was fully superseded by the latest pressure equipment directive 2014/68/EU from 20 July 2016 onwards.

Under the Community regime of the Pressure Equipment Directive, pressure equipment, and assemblies as defined by the directive have to be safe, must meet essential safety requirements covering design, manufacture, and testing; must satisfy appropriate conformity assessment procedures; and carry the CE marking and other information.

Exclusions from PED

As per the pressure equipment directive, the following items/equipment are excluded:

- vessels containing liquids with pressure not more than 0.5 bar.

- simple pressure vessels covered by Directive 2014/29/EU.

- pipelines comprising piping or systems for carrying fluids or substances to or from an installation.

- networks for the supply, distribution, and discharge of water and associated equipment and headraces such as penstocks, pressure tunnels, pressure shafts for hydroelectric installations, and their related specific accessories.

- aerosol dispensers covered by Council Directive 75/324/EEC.

- equipment and items designed for nuclear use.

- the wellhead (Christmas tree), the blow-out preventers (BOP), the piping manifolds, and all their equipment upstream; used in the petroleum, gas, or geothermal exploration and extraction industry and in underground storage

- high-voltage electrical equipment enclosures such as switchgear, control gear, transformers, and rotating machines;

- exhaust and inlet silencers;

- radiators and pipes in warm water heating systems;

- equipment covered by Directive 2008/68/EC and Directive 2010/35/EU and equipment covered by the International Maritime Dangerous Goods Code and the Convention on International Civil Aviation;

Free Movement within the EU region

All equipment manufactured in accordance with pressure equipment directive guidelines and bearing CE marking can be moved within member states without any restrictions. However, the member states shall perform market surveillance and take all appropriate measures to withdraw the equipment liable to endanger the safety of people, domestic animals, or property.

Product Classification per Pressure Equipment Directive

A manufacturer should categorize the pressure equipment to decide the applicability of the pressure equipment directive. As per Annex II of the pressure equipment directive, there are four conformity assessment categories: Categories I to IV. Category I relates to the lowest and Category IV to the highest, hazardous category.

To determine the exact category of the equipment, the manufacturer should identify the type of equipment; fluid phase, and fluid group. Article 13 of the pressure equipment directive divides fluids into two groups; group 1 and group 2.

Group 1 of PED fluids consists of hazardous fluids like explosives, flammable solids, liquids & gases, pyrophoric liquids & solids, self-reactive substances and mixtures, oxidizing gases, liquids & solids, organic peroxides, toxic fluids, etc. Group 2 consists of all other fluids not mentioned in Group 1.

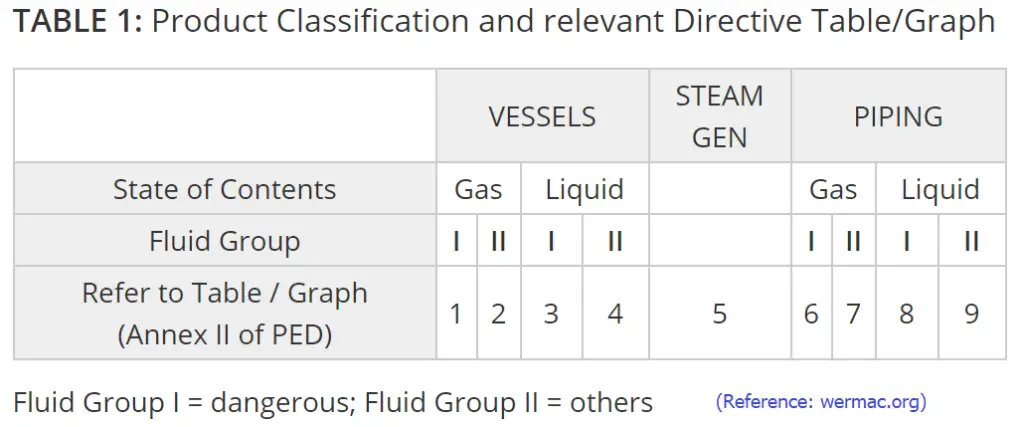

Now based on these fluid groups and conformity assessment category, Annex II provides Pressure vs Volume (for pressure vessels) or Pressure vs Nominal Size (for piping) curves. The manufacturer needs to plot similar pressure curves for their piece of equipment on the relevant Graph to identify the category of the equipment. Normally, the lower the pressure and the volume, the lower the category for the equipment. There is a total of 9 graphs or tables as mentioned in the Pressure equipment directive. Table 1 to Table 4 are for vessels, Table 5 is for Steam or general services and Table 6 to Table 9 is for piping. The following image (Fig. 1) provides a guide for selecting relevant graphs/tables for fluid groups and types of equipment.

Pressure Equipment Directive-Conformity Assessment Procedure

Article 14 of the pressure equipment directive provides guidelines for conformity assessment procedures depending on equipment categories. 13 different conformity assessment modules are provided by the PED for assessment before the release of the equipment in the market. The following image (Fig. 2) lists the conformity modules.

Based on product control or quality systems, manufacturers have to identify a procedure. The modules attributed to a higher hazard category may be used in lower categories. Category I is for manufacturer self-assessment.

Notified bodies appointed by the Member States should be involved during the monitoring, inspection, or approval stages for the modules for products in Categories II, III, and IV. Member states can appoint recognized third-party organizations to carry out the approval of welding procedures and personnel and non-destructive testing personnel. For Modules A1, C1, F, and G; Member states can appoint user inspectorates to carry out the tasks of notified bodies within their organizations. However, in such cases, the CE marking should not be affixed to pressure equipment and assemblies assessed by user inspectorates.

Conformity Declaration and CE-marking

Upon completion of the conformity assessment, the manufacturer is required to affix CE-marking and draw up a Declaration of Conformity for items that comply with the provision of the pressure equipment directive. The CE marking shall be affixed visibly, legibly, and indelibly to each item or assembly of pressure equipment. In situations where the affixing of the CE marking is not possible or not warranted on account of the nature of the equipment or assembly, it shall be affixed to the packaging and the accompanying documents.

Advantages of Pressure Equipment Directive

The major advantages of implementing the pressure equipment directive into force are:

- Simplified assessment using harmonized standards.

- Specific assessment based on hazard categories.

- Certification

- Free movement within the EU region

- All products under the Pressure equipment directive meet the essential safety requirements.

- Proper documentation.

Differences Between PED & ASME

The PED (Pressure Equipment Directive) and ASME (American Society of Mechanical Engineers) standards are both critical frameworks for ensuring the safety and reliability of pressure equipment, but they differ in several key areas. Here is a table summarizing the major differences between PED and ASME:

| Aspect | PED (Pressure Equipment Directive) | ASME (American Society of Mechanical Engineers) |

|---|---|---|

| Governing Body | European Union (EU) | American Society of Mechanical Engineers (USA) |

| Geographical Scope | European Economic Area (EEA) | Primarily USA, but widely recognized internationally |

| Regulatory Nature | Legally binding within EU member states | Voluntary compliance, though often mandated by local laws |

| Certification Process | Requires conformity assessment by a Notified Body | Certification by an Authorized Inspection Agency (AIA) |

| Scope of Standards | Covers design, manufacturing, and conformity assessment | Covers design, construction, inspection, and testing |

| Marking Requirements | CE marking for compliance | ASME “U” stamp or other relevant stamps for compliance |

| Design Codes | EN standards (e.g., EN 13445) | ASME Boiler and Pressure Vessel Code (BPVC) |

| Material Requirements | Specific to EU standards | Detailed material specifications in ASME BPVC Section II |

| Inspection and Testing | Involves third-party inspection by a Notified Body | Involves third-party inspection by an Authorized Inspector |

| Documentation | Comprehensive technical documentation for conformity | Detailed documentation and reports as per ASME code |

| Quality Assurance | Emphasis on quality assurance throughout the supply chain | Quality assurance systems like ASME’s Nuclear Quality Assurance (NQA-1) |

| Updates and Revisions | Periodically updated through EU directives | Regular updates through ASME code committees |

| Risk Categories | Classified into different categories based on potential hazard | Uses design rules and factors of safety for different classes of equipment |

Further Studies

- https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:02014L0068-20140717

- https://ec.europa.eu/docsroom/documents/41641/attachments/1/translations/en/renditions/native

The Pressure Equipment Directive (2014/68/EU) is a legislative framework at European level for pressure equipment presenting a pressure hazard and, thus, not a set of guidelines.

For more information: https://ec.europa.eu/growth/sectors/pressure-gas/pressure-equipment_en

Thanks for this article.

For category II it’s the module A2 and not A1 as stated in the table 2. I believe it’s a typo in the source.