In the world of oil and gas production, the terms “Christmas tree” and “wellhead” hold significant importance. These components are crucial for the safe and efficient extraction of hydrocarbons from beneath the Earth’s surface. While they might seem like simple structures, their design and functionality encompass a wide range of engineering principles, safety considerations, and operational strategies.

1. Christmas Tree in Oil & Gas

1.1 What is a Christmas Tree?

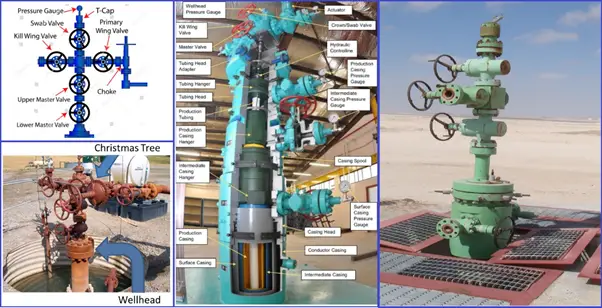

In petroleum and natural gas extraction, a Christmas tree, or “tree,” is an assembly of a multi-valved structure consisting of valves, pipe spools, and fittings used to control the flow of oil from the well. The shape of the wellhead structure with valves looks like a pine tree, so the wellhead is called a “Christmas tree”. The Christmas Tree is connected to the top of the tubing and cemented to the top of the casing. These valves regulate pressure, control flow, and allow access to the wellbore when further completion work is required. From the outlet valve of the Christmas Tree, the flow can be connected to a distribution network of pipelines and tanks to distribute the product to refineries, natural gas compressor stations, or oil export terminals.

The Christmas tree is the heart of the offshore hydrocarbon production system. It is the primary means of well control and plays a key role in the emergency shutdown system. The Christmas tree sits on the top of the wellhead casing system and represents the interface between the well and the production and process facility.

The Christmas tree consists of an assembly of a gate valve that controls the flow of hydrocarbons. It may consist of individual valves bolted together, or it may feature a cast or forged steel solid block into which the valve chests are machined. Occasionally it is a combination of the two. In all cases, the valve seats and gates are removable for replacement or repair.

1.2 The Function of a Christmas Tree

The primary function of a Christmas tree is to manage the flow of oil and gas from the well. It serves several key purposes:

- Flow Control: Regulating the flow rate of oil and gas to optimize production.

- Pressure Management: Maintaining appropriate pressure levels within the well to prevent blowouts.

- Separation of Fluids: Allowing for the separation of oil, gas, and water as they are extracted.

- Safety Measures: Providing emergency shut-off capabilities to prevent uncontrolled releases of hydrocarbons.

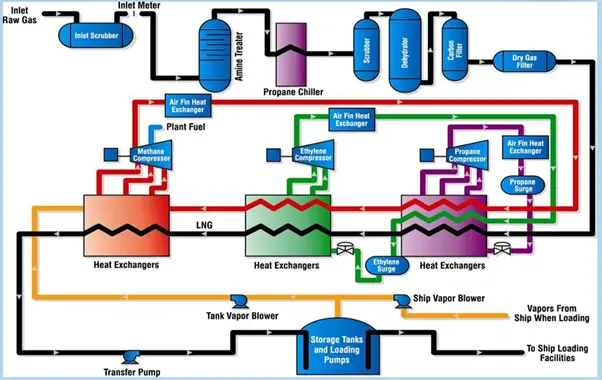

In producing wells, injection of chemicals, alcohols, or oil distillates to prevent or solve production problems (such as blockages) may be used.

A tree may also be used to control the injection of gas or water injection applications on a producing or non-producing well in order to sustain economic “production” volumes of gas from other wells (s) in the area (field).

The control system attached to the tree controls the downhole safety valve while the tree acts as an attachment and conduit means of the control system to the downhole safety valve.

1.3 Components of a Christmas Tree

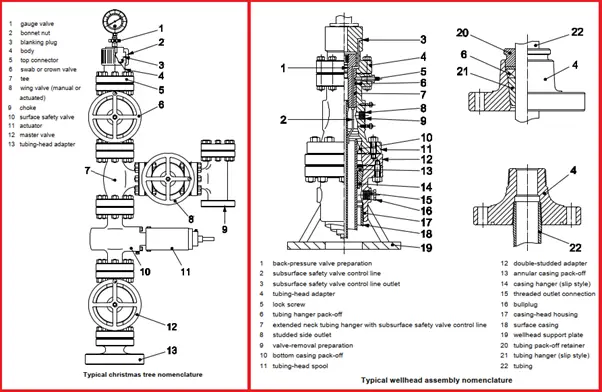

A typical Christmas tree is composed of a master gate valve, a pressure gauge, a wing valve, a swab valve, and a choke as shown in Fig. 1. The Christmas tree may also have a number of check valves.

At the bottom, we find the casing head and casing hangers. The casing will be screwed, bolted, or welded to the hanger. Several valves and plugs will normally be fitted to give access to the casing. This will permit the casing to be opened, closed, bled down, and, in some cases, allow the flowing well to be produced through the casing as well as the tubing. The valve can be used to determine leaks in the casing, tubing, or packer, and will also be used for lift gas injection into the casing.

The tubing hanger (also called a donut) is used to position the tubing correctly in the well. Sealing also allows Christmas tree removal with pressure in the casing.

There are wells drilled into the reservoir, and the central conductor, along with the surrounding jackets/annulus, rises up to the production deck/cellar deck of the platform. On top of the wellhead, an assembly of valves is placed, which has the form of a cross. This assembly of valves together with the flanges is called a wellhead Christmas tree.

The Christmas tree has many Manual valves and a number of actuated valves. The actuated valves usually found on the Christmas tree are as follows:

1.3.1 Sub-Surface Safety Valve:

The Sub-Surface Safety valve is a hydraulic operated valve, the location of which is below sea level, above the sea bed. The actuator of this valve needs to be very small, as it gets enclosed within the Annulus of the conductor. The actuator is usually hydraulically operated. The control line for the hydraulic supply for the SSSV runs within the conductor and terminates at a connection on the Christmas tree.

1.3.2 Surface Safety Valve or Master Valve:

This isolates the tree from the production tubing. The Christmas tree has two master valves referred to as the upper and lower master valves. The lower master valves are opened first and closed last. This ensures a minimal flow of hydrocarbon over the valve seat, thus protecting it from abrasive particles and ensuring a good seal is maintained.

In most cases, the lower master valve is manually operated and the upper master valve is operated via a hydraulic or pneumatic actuator and is connected to the emergency shutdown system. The actuators are fail-safe in operation. The valve is held open by oil or pressure against a compressed coil spring.

The master gate valve is a high-quality valve. It will provide a full opening, which means that it opens to the same inside diameter as the tubing so that specialized tools may be run through it. It must be capable of holding the full pressure of the well safely for all anticipated purposes. This valve is usually left fully open and is not used to control flow.

A master valve is the first actuated valve on the Christmas tree, located above the Mezzanine deck of the platform. The Actuator is bigger and can be pneumatic or Hydraulic, based on the Christmas tree requirement

The pressure gauge:- The minimum instrumentation is a pressure gauge placed above the master gate valve before the wing valve. In addition, other instruments such as temperature will normally be fitted.

1.3.3 Wing Valve:

The wing valve comes on the arm of the Christmas tree, on the line where the flow line starts. The actuator is again hydraulic or pneumatic based on the requirement. The wing valve can be a gate valve or a ball valve. When shutting in the well, the wing gate or valve is normally used so that the tubing pressure can be easily read.

Christmas trees may be manufactured with one or two wing valves. One valve is permanently connected to the hydrocarbon process system and is fitted with a hydraulic or pneumatic actuator. The other valve is manual in operation and permits the injection of chemicals or gases into the well without disturbing production pipework.

Both valves are offset from the vertical lines so that a clear entry into the well is maintained through the swab valve for wireline work. The flow of gas from the well is regulated by wing valve operation or by choking fitted above the wing valve.

Hydraulic tree wing valves are usually built to be fail-safe closed, meaning they require active hydraulic pressure to stay open.

The right-hand valve is often called the flow wing valve or the production wing valve because it is in the flow path the hydrocarbons take to production facilities.

The left-hand valve is often called the kill wing valve. It is primarily used for the injection of fluids such as corrosion inhibitors or methanol to prevent hydrate formation.

1.3.4 Well Service Valve:

The Well Service Valve may be present on some Christmas trees, where Diesel pumping is required for initial start-up. It is on the other arm of the Christmas tree, and usually, the size is lesser than that of the wing valve.

The valve at the top is called the swab valve and lies in the path used for good interventions like wireline and coiled tubing. A ‘Choke’ is a device, either stationary or adjustable, used to control the gas flow, also known as volume, or create downstream pressure, also known as back pressure.

The Wellhead valves are all controlled by a Well Head Control panel, which gives the hydraulic & pneumatic supply for opening/closing these valves. There is logically built in the WHCP for allowing the safe closure of all these wellhead valves, in case of an emergency, either due to process upset or due to emergency/fire. In addition to these valves, the other instrumentation which is associated with the Christmas tree is the Pressure gauges and Transmitters for monitoring the Annulus pressures, the Flowing Tube Head Pressure, etc.

1.4 Vertical Christmas Tree vs Horizontal Christmas Tree

1.4.1 Vertical Christmas Tree:

The master valves are located above the tubing hanger, and swab valves together with master valves are stacked vertically. The production and annulus bore lay vertically on the body of the tree. The well completion is finished before installing the vertical Christmas tree. Since the tubing hanger rests on the wellhead, the Christmas tree can be recovered without having to recover the downhole completion. This type is generally applied in subsea fields due to its flexibility in installation and operation.

1.4.2 Horizontal Christmas Tree:

In contrast to the vertical Christmas tree, the valves of the horizontal Christmas tree are located on the lateral sides of the horizontal Christmas tree, allowing for easy well intervention and tubing recovery, thus this type of tree is very feasible for the wells that need many interventions. The tubing hanger is installed in the tree body instead of the wellhead. Consequently, the tree is installed onto the wellhead before the completion of the well.

2. Wellhead in Oil and Gas

2.1 What is a Wellhead?

A wellhead is a structure that sits at the surface of an oil or gas well, providing a point of access for drilling and production operations. It is essentially the terminal point of the wellbore, serving as the interface between the well and the surface.

A wellhead skid controls the operation of the Christmas tree and mudline safety valves. The skid permits valves to be operated locally, remotely, or via an ESD system, and timing, mechanisms provide a means of controlling the speed and sequence of valve operation. This sequence would normally be close to the wing valve, master valve, and mudline safety valve.

During an ESD operation, complete closure of the Christmas tree valves should be effected within approximately 45 seconds according to API recommendations, the only organization to provide guidance on this particular aspect.

Wellheads can be Dry or Subsea completion. Dry completion means that the well is onshore on the topside structure on an offshore installation. Sub-sea wellheads are located underwater on a special sea bed template. The wellhead consists of the pieces of equipment mounted at the opening of the well to regulate and monitor the extraction of hydrocarbons from the underground formation. It also prevents the leaking of oil or natural gas out of the well and prevents blowouts due to high-pressure formations. Formations that are under high pressure typically require wellheads that can withstand a great deal of upward pressure from the escaping gases and liquids.

These wellheads must be able to withstand very high pressures of the order of 140 MPa (1400 Bar).

2.2 Components of a Wellhead

A typical wellhead assembly consists of several key components:

- Casing Head: The part that connects the well casing to the wellhead assembly.

- Casing Spool: A cylindrical section that provides a place for the casing to connect and helps manage pressure.

- Christmas Tree: Often integrated with the wellhead, as discussed earlier.

- Blowout Preventer (BOP): A safety device that prevents the uncontrolled release of oil or gas during drilling.

- Valves: Various valves control the flow of fluids and provide safety shut-off options.

2.3 Importance of Wellheads

Wellheads are critical for the integrity and safety of drilling operations. They ensure that the well is sealed off to prevent contamination of groundwater and minimize environmental risks. They also facilitate maintenance and monitoring activities throughout the lifecycle of the well.

3. The Interplay Between Christmas Trees and Wellheads

Integration in Operations

While Christmas trees and wellheads serve distinct functions, they are often integrated into a single assembly for efficiency and safety. This integration allows for streamlined operations, from drilling to production.

Safety Considerations

Both Christmas trees and wellheads play crucial roles in the safety of oil and gas operations. They are designed to withstand extreme pressures and temperatures, and they include multiple redundancies to ensure reliable performance.

4. Materials Used

The materials used in constructing Christmas trees and wellheads must withstand harsh environmental conditions. Common materials include:

- Alloy Steel: Utilized in high-pressure applications.

- Carbon Steel: Used for structural components due to its strength and durability.

- Stainless Steel: Often used for valves and fittings to resist corrosion.

5. Christmas Tree vs Wellhead?

In the complicated but vital industry of drawing oil and gas out of the earth and getting it to the surface, people often get confused about the difference between a Christmas tree assembly and a wellhead. Although the terms are used interchangeably, a wellhead and a Christmas tree are entirely separate pieces of equipment. Each has valves and related equipment that help it control and guide the flow of this precious resource. A wellhead must be present in order to utilize a Christmas tree and is used without a Christmas tree during drilling operations. Producing surface wells that require pumps (pump jacks, nodding donkeys, etc.) frequently do not utilize any tree due to no pressure containment requirement.

Basically, The Christmas tree and the wellhead work together to bring oil and gas to the surface.

A tree often provides numerous additional functions including chemical injection points, well intervention means, pressure relief means (such as annulus vent), well monitoring points (such as pressure, temperature, corrosion, erosion, sand detection, flow rate, flow composition, valve and choke position feedback, connection points for devices such as downhole pressure and temperature transducers.

6. Design Code for the Christmas tree and wellhead

Christmas Tree and Well Head Equipment is designed following API Specification 6A/ISO 10423. The design shall take into account the effects of pressure containment and other pressure and temperature-induced loads. The following Figure (Fig. 2) shows the typical nomenclature of parts used in describing the Christmas Tree and wellhead.

The Christmas tree and wellhead are vital components of the oil and gas industry, playing critical roles in the extraction and management of hydrocarbons.

Could you please provide more info on annulus

Is it important to keep master valves in good working order. Is there any specific maintenance that needs to be done on a specific schedule.

Good work, my friend, thank you for your sharing of your knowledge.

I need pdf

Good info, thanks

The Christmas tree has five main valves and a wellhead cap for each string of the well.

The valves are always gate type valves.

1. The lowest valve is called the lower master valve and is used to isolate the well fluids

from the Christmas tree.

2. Above the lower master valve is the upper master valve and it is used as a second

isolation of well fluids.

3. Above the upper master valve is the wing valve which has one end on the Christmas

tree, while the other end is the start of the well flow line.

4. The Valve opposite to wing valve and flow line is Kill wing valve. It is used to kill the

well (Only in single string wells).

5. Above both of these valves is the swab valve. This is used for wire line operations to provide an isolation between the wire line equipment (the lubricator) and the well itself.