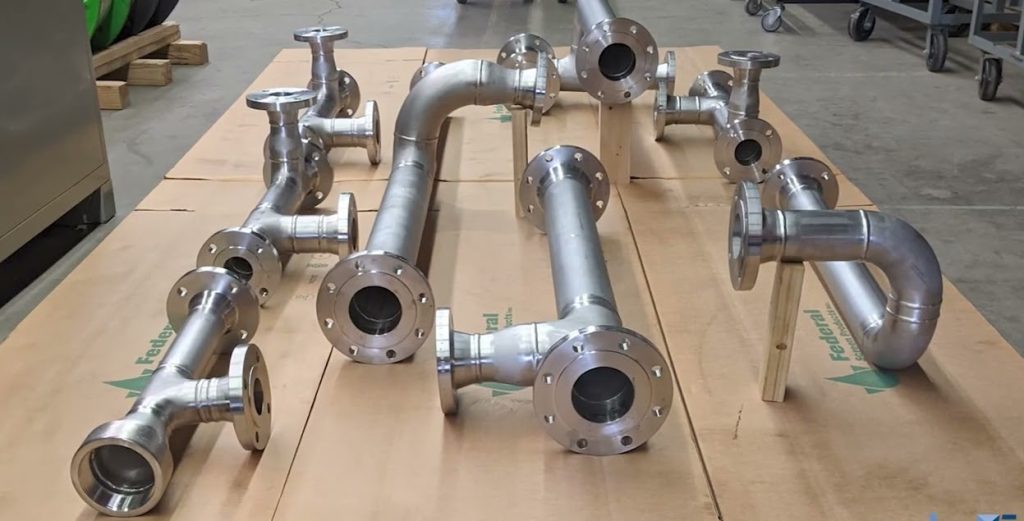

A pipe spool is a prefabricated, smaller segment of piping that is assembled and tested in a workshop before being delivered to the construction site for installation. It typically includes the pipe itself along with any necessary fittings, flanges, and other components. Pipe spools are commonly used in industries like oil and gas, chemical processing, power generation, and construction where complex piping systems are required. Pipe spool fabrication involves a series of cutting, beveling, welding, painting, coating, lining, and other processes in the pipe fabrication shop or offsite facility. Once the piping spools are produced, they are taken to the construction site and installed. Fig. 1 below shows some typical pipe spool images.

Reasons for Pipe Spooling

Pipe spooling streamlines the construction process, improves quality and safety, and often leads to cost savings. There are several reasons for pipe spooling during construction:

- Efficiency and Speed: Prefabricating pipe spools in a workshop or fabrication facility allows for faster assembly than on-site construction. This can significantly reduce the overall construction timeline.

- Quality Control: Fabricating and testing spools in a controlled environment ensures higher quality and consistency. It’s easier to adhere to precise specifications and standards in a workshop setting.

- Reduced Site Work: With pipe spools pre-assembled, the work required on the construction site is minimized. This reduces labor costs and potential disruptions and can be especially beneficial in complex or hazardous environments.

- Error Reduction: Pre-fabrication allows for thorough inspection and testing before installation. This helps identify and correct potential issues before the spools are delivered to the site, reducing the likelihood of errors during installation.

- Improved Safety: By completing complex or dangerous tasks in a controlled environment, workers on the construction site face fewer risks, contributing to overall safety.

- Cost Savings: Efficient use of materials and labor, combined with reduced on-site installation time, can lead to cost savings in the overall project.

- Standardization: Pipe spooling helps ensure that components are standardized and uniform, making it easier to manage and install the piping system.

Parts of a Piping Spool

A piping spool usually consists of three main parts: the pipe, flange, and any pipe fitting.

The pipe is the primary component in a pipe spool. Flanges are used as the connectors of two pipe segments. Several types of pipe fittings are used for directional changes of the pipe. Sometimes piping supports like pipe shoes can also be attached to the pipe spool.

What is Pipe Spool Fabrication?

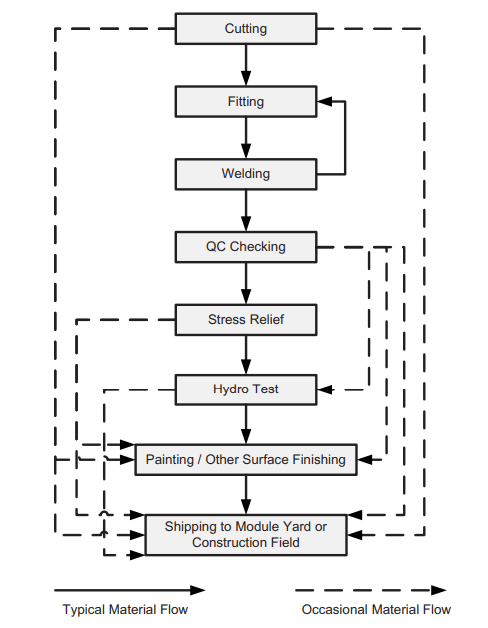

Pipe spools are fabricated off-site to reduce assembly time by using various raw pipes and fittings, including flanges, elbows, tees, and more. The process begins by following a pipe spool drawing and using raw pipes being precisely cut to size, and these are then assembled with pipe fittings and other components into a temporary sub-assembly. This partial assembly is then welded together, forming the basic structure of the spool. The fabrication process is divided into two main phases: spool roll fitting and welding, followed by spool permanent position fitting and welding. This structured approach ensures efficiency and precision in creating the final pipe spools. The flowchart for the spool production stages is provided in Fig. 2 below:

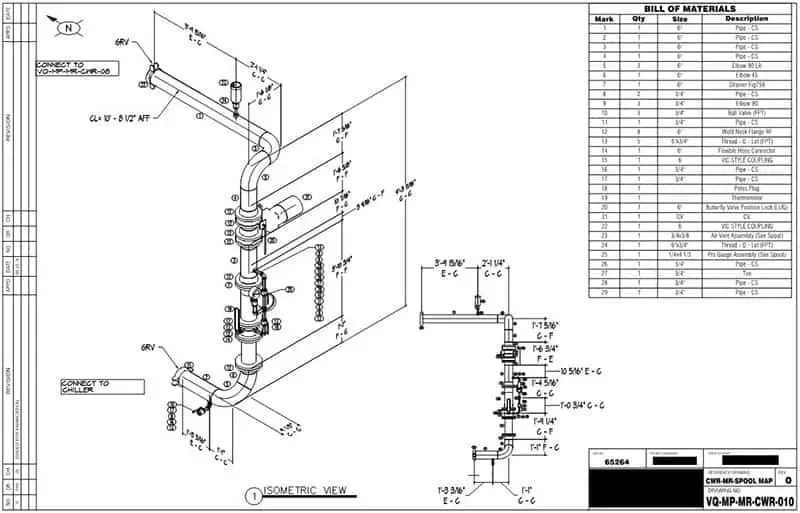

Pipe Spool Drawing

A pipe spool drawing is a detailed technical illustration used in the design and fabrication of pipe spools. It provides a comprehensive view of how the components of a pipe spool should be assembled and installed. Key elements typically included in a pipe spool drawing are:

- Dimensions: Accurate measurements of the pipe lengths, fittings, and other components to ensure correct assembly and installation.

- Component Details: Identification and specifications of all parts involved, such as pipes, elbows, tees, flanges, valves, and supports.

- Welding and Joint Details: Information on welding procedures, joint configurations, and connection types, including weld types and sizes.

- Material Specifications: Details about the materials used for the pipe and fittings, including material grades and standards.

- Annotations: Notes and symbols indicating important instructions or requirements for installation, such as orientation, alignment, and special handling.

- Isometric View: A three-dimensional representation of the spool, showing the spatial arrangement of components and their relationships to one another.

- Bill of Materials: A list of all materials and components required for the spool, including quantities and part numbers.

Pipe spool drawings are essential for ensuring that all parts fit together correctly, meet design specifications, and adhere to industry standards. They serve as guides during fabrication and installation, helping to streamline the construction process and minimize errors. Fig. 3 below provides a typical sample pipe spool drawing.

Pipe spools are an integral component of modern industrial piping systems. These sections are assembled in a controlled environment—usually a fabrication shop—before being transported to the construction site for installation. Pipe spools are designed to streamline the construction process by allowing sections of the piping system to be built, tested, and inspected off-site, reducing the amount of on-site assembly work and minimizing potential errors.