What is a Sour Environment?

NACE defines a Sour environment as one that contains enough H2S either in the gaseous or aqueous media.

Properties of Hydrogen Sulphide

- Chemical Formula: H2S

- Odour: Rotten Egg

- Boiling point: 60OC

- Specific Gravity: 1.19

- Odour level: 0.13 mg/kg

The fatality of Hydrogen Sulphide (mg/kg)

- Respiratory breakdown: 100

- Nerve paralysis: 150

- Nausea, Dizziness: 200

- Unconsciousness: 500

- Asphyxiant, Fatal: 700

What is Sour Service?

Sour Service is defined as a fluid service containing water as liquid & H2S exceeding the limits defined below:

Sour Gas-

Sour Gas Service is defined as the gas service

IF the Total Pressure of the gas being handled is > = 65 PSIA

AND Partial Pressure of H2S in the gas is > 0.05 PSIA

Then The Environment is SOUR Gas

Sour Oil and Multi-phase

IF the Fluid handled is Crude or Crude+Water+Gas

AND

- Gas to Oil Ratio > 5000 (SCF/bbl)

- H2S content in Gas-phase > 15%

- Partial Pressure of H2S in Gas Phase > 10 PSIA

- Surface operating Pressure > 265 PSIA

Then The Environment is SOUR Oil

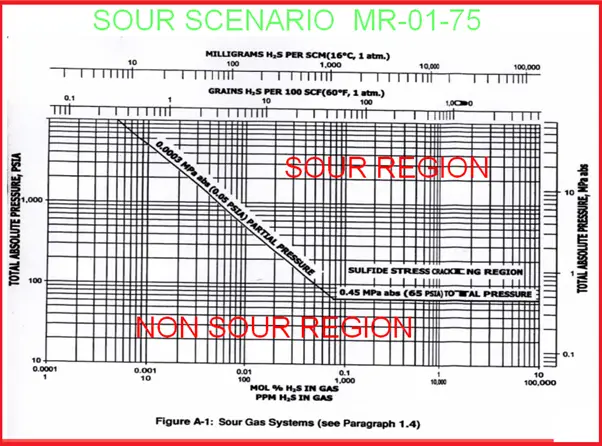

Sour Scenario in the oil industry as per NACE MR-01-75

Refer to the below image (Fig. 1) which shows a curve segregating the sour and non-sour regions as per NACE MR-01-75. The curve denotes the amount of H2S requirement for qualification of being Sour at a given absolute pressure.

Limitations of NACE MR-01-75

- Saltwater wells, injection wells

- Downstream Industries, Petrochemical

- Refineries and Chemical plants

- Low-pressure multiphase systems

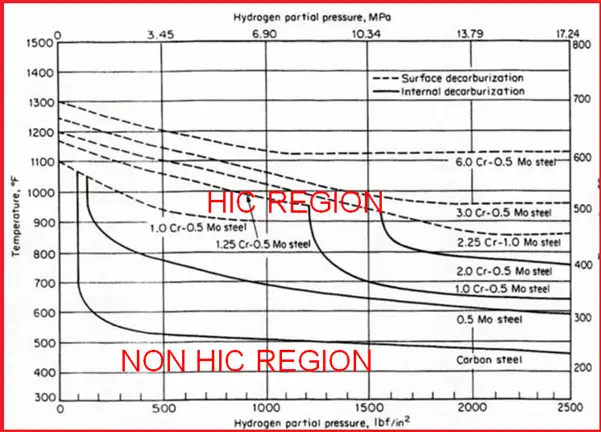

HIC Scenario – API Nelson Curves

Refer to Fig. 2 which shows the HIC and Non-HIC regions.

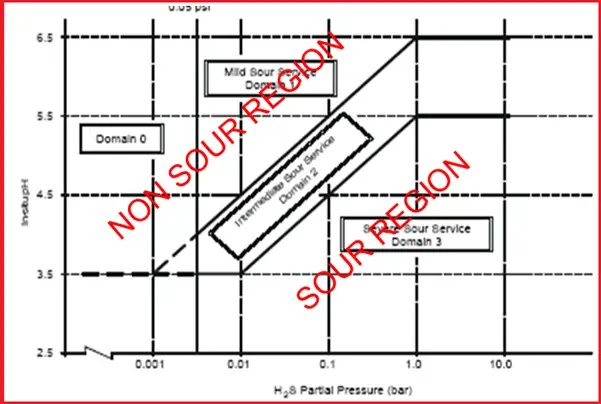

Sour Scenario as per ISO 15156 / EFC 16

Fig. 3 shows the sour service criteria as per ISO 15156/EFC 16.

Sour Service H2S ppm Criteria as per DEP

Shell DEP provides the following H2S criteria for fluid services

- 0 to 49 PPM: Sweet Service

- 0 to 499 PPM: Low-Risk Sour Service

- 500 + PPM: High-Risk Sour Service

Hydrogen Sulphide – What it Can Do!

- Hydrogen- Hydrogen Induced Cracking (HIC)

- Sulphide- Sulphide Stress Cracking (SSC)

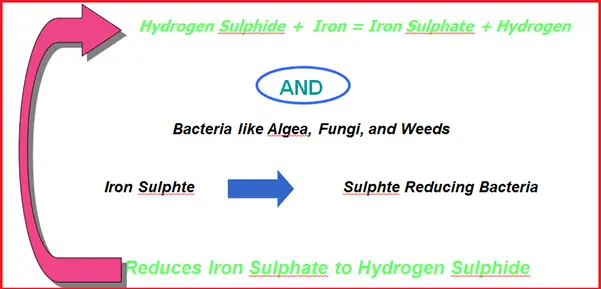

Dynamics of Sour Environments

Fig. 4 shows the dynamics of the sour service environment.

For more understanding of NACE Services, I suggest the following course: NACE CIP 1 practice exam

interesting article!

Some of the information you are presenting is out of date or misleading. I strongly recommend to update the content.

Anup, Can there be a scenario in which Water Injection pipeline be in “Sour Service” environment? My understanding is no, as Injection water will not have H2S. Could you clarify. My e-mail is sanjivs@npcc.ae

Yes, Water Injection pipeline can be in “Sour Service” if water is injected from GOSP residual water, like saltwater disposal from GOSP

Thanks for sharing but please let me what is the reference for this figure