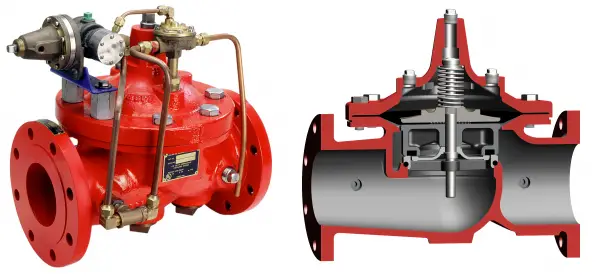

A deluge valve is a critical component of the deluge system used in fire protection services. During fire events, deluge valves are activated quickly and deliver a large volume of water over the protected area to extinguish the fire for protecting life and property. Because of this, deluge valves are known as the heart of a deluge system. They are activated by a detection system and operate as a system control valve. A deluge valve consists of an inlet, outlet, and a priming chamber. They can work in both vertical and horizontal installations. Deluge valves are widely used in Oil & gas industries, power plants, tank farms, foam systems, paper industries, car industries, petrochemical onshore and offshore installations, etc. Viking and Tyco are the industry leaders in manufacturing deluge valves. Fig. 1 below shows an image of a typical deluge valve.

Working of a Deluge Valve

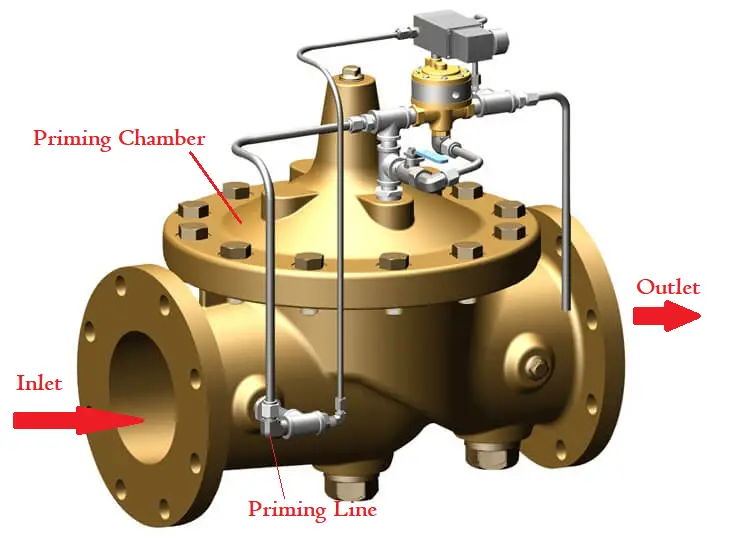

The deluge valve is a quick-acting, hydraulically operated diaphragm valve consisting of three chambers (Refer to Fig. 2), isolated from each other by the diaphragm-operated clapper and seat seal.

Pressurized water is supplied to the priming chamber through an external bypass check valve and restriction orifice system during set position. The pressure of the water trapped in the priming chamber holds the diaphragm on the valve seat, keeping the valve closed.

Upon detection of fire, the pressure from the control chamber is released by a manual or automatic release device. So, the top chamber pressure of the deluge valve falls below the supply pressure forcing the diaphragm of the seat. Water from the inlet side flows into the piping network and alarm devices.

Deluge Valve Types

Depending on the trim used in a deluge valve they are categorized as follows:

- Basic Type

- Dry Pilot Trim type

- Wet Pilot Trim type

- Electric Release Trim type

- Test and Alarm Trim with Sprinkler

Basic Trim Type Deluge Valve:

Basic trim is required for all types of deluge valves regardless of the release system. Typical components of a basic trim-type deluge valve are the main drain valve, drip check valve, priming connection, emergency release valve, and pressure gauges.

Dry Pilot Trim Type Deluge Valve:

Dry pilot trim type deluge valves are known as pneumatic release type as it uses a pilot line containing dry air under pressure. The pilot line is connected directly to the top of the Positive Drain Actuator (PDA). The bottom of the PDA is connected to the top chamber of the deluge valve.

Due to the release of any of the release devices on detection of fire, the air pressure drops and the diaphragm of the PDA is lifted allowing the water to drain. This reduces the water pressure in the top chamber of the deluge valve and when the pressure in the top chamber reaches 50% of the supply pressure, the deluge valve opens.

Wet Trim Type Deluge valve:

A wet pilot trim type deluge valve uses a pilot line of closed sprinklers containing pressurized water for its operation. The water is supplied through the upstream side of the deluge valve, through a restricted orifice. All the release lines are connected to a common release line. When any of the release devices are released, the water pressure of the deluge valve top chamber falls to 50% of the supply pressure allowing the supply air to flow.

Electric Release Trim Type Deluge Valve:

As the name indicates, such type of deluge valve is actuated electrically. To activate an electric trim-type deluge valve, a solenoid valve is provided to drain the water from the valve top chamber. An electric alarm is activated by a pressure switch that shuts down the desired equipment or gives an indication for tripping to the control panel.

Test and Alarm Trim with Sprinkler:

Test and Alarm Trim with Sprinkler: Such trim is supplied along with the sprinkler alarm bell that bells on activation of the deluge valve. To test the normal operation of the sprinkler alarm bell, a test valve is provided.

Depending on the number of priming chambers two types of deluge valves are found.

- Single chamber deluge valve and

- Double chamber deluge valve

Single-chamber deluge valves are the traditional diaphragm-type valves with an inlet chamber connected to the deluge valve supply side and an outlet chamber connected to the fire suppression system side. Such deluge valves have only one prime chamber. These valves need low maintenance and provide an obstacle-free water path minimizing pressure loss.

Double chamber deluge valve design combines all the functions available on the traditional deluge valves with a fully redundant architecture and it provides higher reliability. Constituting two priming chambers, with their own diaphragm and actuation trim, such valves offer two independent waterways to the water spray system. Each priming chamber provides the nominal design waterway for the fire protection system. If one diaphragm fails, the other diaphragm opens allowing the hydraulic waterway for the correct operation of the water spray system.

Materials for Deluge Valve

A variety of different materials are used to produce a deluge valve depending on the requirement. Common deluge valve materials are

Advantages and Disadvantages of a Deluge valve

The deluge valve provides the following advantages:

- Quick response.

- A large quantity of water is available in a shorter time period.

- Low cost

- Designed to be reset without opening the valve

- Possibility of inline maintenance.

- Obstacle-free, full bore

The main drawbacks of a deluge valve are:

- It can damage sensitive or electronic equipment.

- Longer cleaning time than dust and gas systems.

- It requires a large water reservoir for its operation.

Click here to know about: Deluge System: Definition, Working, Applications, and Advantages

Good post, keep going.

I am a graduate of mechanical engineering HND holder . I have interest in piping engineering. For sometime I have been looking for a company to obtain training on it,So looking forward to learn more from you on piping engineering construction and other useful information that will result in working in any pipe construction company. Thanks

Hi Anup, you have put in a clear concise summary of the system.Great effort..

Cheers,Harish

Nice one

Dear sir, I am working in fire fighting installation company.Let me know how to set H3 deluge valve, vertical mounted,wet type

Do you know of a listed deluge valve that can be installed in a dry system?