An accelerometer is an electro-mechanical device that measures the acceleration of motion of a pipe, equipment, or structure. This is a very useful tool for vibration engineering and is widely used to measure vibration in operating plants. The vibrating force produces an electrical signal which is captured by the sensors of the accelerometers. The use of accelerometers helps maintenance and inspection engineers understand a machine’s stability and help them monitor it to take future decisions. In this article, we will learn more about accelerometers, their working, function, selection, and types.

Working Principle of an Accelerometer

Accelerometers use sensors to sense static or dynamic acceleration forces. Static acceleration is created due to the constant forces that act on an object like gravity force or friction force. These forces are known and uniform and can easily be calculated to a large extent.

On the other hand, dynamic acceleration forces like vibration or shock are sudden, non-uniform, and can not be easily predicted. The accelerometers can detect and measure the acceleration on one, two, or three axes and convert it into electrical signals.

In general, accelerometers are equipped with internal capacitive plates. Some of these are fixed, while others are attached to minuscule springs. When an acceleration force acts upon the sensor, these plates move internally in relation to each other to cause capacitance change between them. The acceleration is then determined from these changes in capacitance.

Some other types of accelerometers use piezoelectric materials which provide an electrical charge (voltage) when placed under acceleration. There are even more types that use the piezoresistive effect, hot air bubbles, and light.

Types of Accelerometers

To efficiently serve the industry to resolve vibration problems by measuring it, there are broadly three types of accelerometers. they are:

- Piezoelectric accelerometer

- Piezoresistance accelerometer, and

- Capacitive accelerometer.

Piezoelectric Accelerometer

This type of accelerometer uses piezoelectric materials to sense the acceleration change and is used for shock and vibration measurement. There are two types of piezoelectric accelerometers; High impedance charge output accelerometer and low impedance output accelerometer.

In a High impedance charge output accelerometer, the electrical charge produced by the piezoelectric crystal is connected directly to the measurement instruments. The charge output needs special accommodations and instrumentation. This type of accelerometer can be used even for high-temperature applications (>1200C) when low-impedance models can not be used.

The low-impedance accelerometer consists of a tiny built-in micro-circuit and FET transistor. These elements convert the electric charge into a low-impedance voltage that any standard instrumentation can easily interface. This type of accelerometer is normally used in industry. OMEGA(R) accelerometers are mainly this type of low impedance accelerometers.

Piezoresistance Accelerometer

Piezoresistance accelerometers are much less sensitive than piezoelectric accelerometers and are mainly used for vehicle crash testing. A piezoresistance accelerometer senses the amount of pressure applied to it and increases its resistance in proportion.

Capacitive Accelerometer

The capacitive accelerometer is the most commonly used type of accelerometer. An object’s acceleration is determined by the change in electrical capacitance.

Uses of Accelerometers

Accelerometers find a wide range of applications in industries. They are used in the most complex machines and even handheld devices like smartphones. Some of the real-world applications of accelerometers are listed below:

- Digital Devices: To rotate the display based on the orientation of holding, smartphones, tablets, and digital cameras use accelerometers.

- Vehicles: Accelerometers are responsible for triggering airbags during a vehicle accident. The accelerometers installed in the cars send a signal when it experiences a sudden shock.

- Drones: Drones stabilize their orientation mid-flight with the help of accelerometers.

- Rotating Machinery: The vibrations in any component in rotating machinery are measured by accelerometers and then studied to find the cause of vibration.

- Industrial Platforms: Accelerometers are used to measure platform stability or tilt.

- Vibration Monitoring: To monitor the vibration of any equipment, piping, or other structural component accelerometers are proved to be very useful.

- Sports: The wearable devices of athletes comprise accelerometers or gyroscopes to track improvements.

- Medical Industry: Physicians use accelerometers to check gain in body mass and monitor body movements. The heart rate measuring device also uses this device.

- Even using accelerometers, Zoologists track animal movement inside the jungles.

Some other applications of accelerometers include the following:

- Bearing Analysis

- Gearbox Monitoring

- Balancing

- Biomechanics

- Impulse Response

- Building Vibration Monitoring

- Bridge Monitoring

- Component Durability Testing

- Drop Testing

- Fatigue Testing

- Environmental Testing

- Vibration Isolation

- Ground Vibration Tests

- Impact Measurements

- Modal Analysis

- Structural Testing

- Package Testing

- Product Qualification

- Pyroshock

- Quality Control

- Research & Development

- Seismic Monitoring

- Squeak and Rattle

- Structure-borne Noise

- Vibration Stress Screening

Selection of an Accelerometer

The proper selection of an accelerometer depends on various parameters as listed below:

- Vibration amplitude and frequency range are to be monitored.

- Temperature range of the pipe/equipment requiring vibration measurement.

- Size and shape of the sample to be monitored

- Working environment

- Presence of electromagnetic fields and noise

- Requirement of Intrinsically safe or explosion-proof instruments.

- Output required; analog or digital.

- The number of axes for measurement; one, two, or three-axis measurement.

- Maximum swing required.

- Sensitivity required.

- Bandwidth required.

- Power requirement.

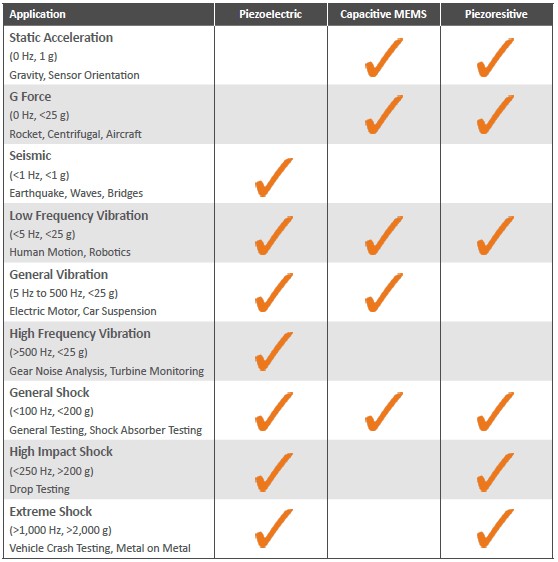

The following image (Courtesy: blog.endaq.com) provides a typical guideline for selecting an accelerometer.

Mounting an Accelerometer

For proper mounting of any device, it is always better to read and follow the manufacturer’s manual. In general, the sensor is directly mounted to the machine’s surface where vibrations need to be measured. There are several types of mounting methods for direct surface mounting including:

- Flat Magnet Mount

- 2-pole Magnet Mount

- Adhesives (Epoxy/Cyanoacrylate)

- Mounting Stud

- Isolating Stud

Magnet Mounts are used for temporary mountings on ferromagnetic materials. This type of mounting allows the sensor to be easily relocated from one location to the other for multiple readings. For mounting on a curved ferromagnetic surface, two-pole magnetic mounts are used.

Adhesives such as epoxy or cyanoacrylate and threaded studs are normally considered for permanent mountings. Mounting studs provide solid reliable mountings but require the structure to be drilled and tapped.

Characteristics of an Accelerometer

All accelerometers should possess the following characteristic features:

- Rugged and durable

- High stiffness

- Very repeatable

- Wide dynamic range

- Fast rise time

- High-useable frequency range

Communication Interface

Accelerometers communicate over an analog, digital, or pulse-width modulated connection interface.

- Analog Accelerometers show accelerations through varying voltage levels which normally fluctuate between the ground and the supply voltage level. Analog accelerometers are cheaper than digital accelerometers.

- Digital Accelerometers communicate over SPI or I2C communication protocols which have more functionality and are less susceptible to noise than analog accelerometers.

- Accelerometers with output data over pulse-width modulation (PWM) output square waves with a known period, but a duty cycle that varies with changes in acceleration.