The Rotary Selector Valve or RSV was developed in the early 1900s for use in irrigation systems. By the late 1940s, the product found favor in the growing oil and gas industry throughout Texas and California. The purpose of the unit was to manifold multiple wells into a single group flow line to feed various containment vessels or production facilities and maintain the ability to test single specific wells or sources on command.

Today the RSV is used widely throughout the oil and gas industry in addition to the chemical, refinery, water treatment, pulp and paper, cementing, food production, and general industry applications.

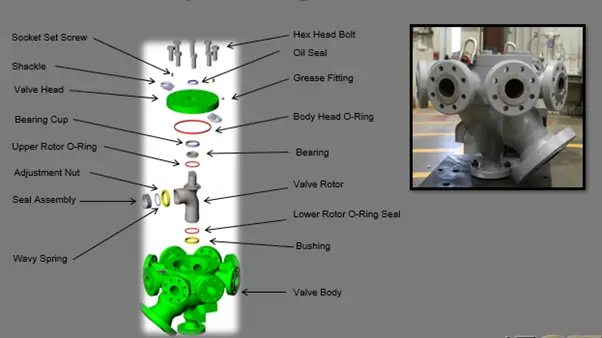

Rotary Selector Valve (RSV-Fig. 1) Components:

- RSV Actuator

- Heat Shield

- Riser Kit

- Thermal Coil

- Thermal Blanket

- Mounting Brackets

- Lifting Pads

Applications:

A multiport valve can be used for fluid or gas systems

- Multiple-port flow

- Single port testing

- Manual or automated operation

- Water injection

- Collection at the tank battery

- Other-market application

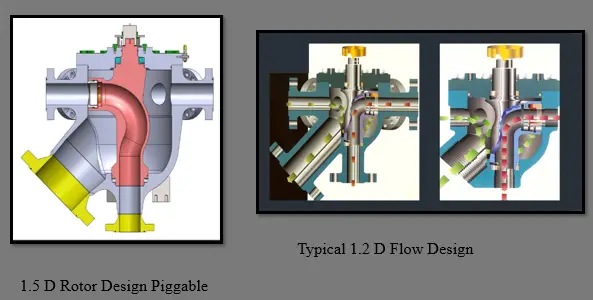

The RSV supports the capability of diverting multiple inlet ports, allowing each port to flow uninterrupted into a single chamber known as the body of the valve and out through a single group outlet port. A rotor stem, positioned in the center of the bowl, allows for the selection of a single inlet source to be diverted through a 1.2D or 1.5D flow line elbow and out through a single test outlet port.

The valve position is controlled by manual or automatic operation. Manual operation requires placing an indexing wrench directly on the outer stem of the rotor and rotating to the selected stopping position. The automatic operation uses a hydraulic, pneumatic, or electrical controller that attaches directly to the outer stem of the rotor allowing for local or remote positioning of the rotor to a selected port.

Advantages of Rotary Selector Valves

A rotary selector valve, also known as a rotary valve, is a type of valve used to control the flow of fluids or gases in a pipeline. It consists of a rotating cylinder that is divided into a series of compartments or ports. As the cylinder rotates, the ports align with the inlet and outlet ports, allowing the fluid or gas to flow through.

Rotary valves are commonly used in industrial applications, such as chemical and petrochemical processing, food and beverage production, and pharmaceutical manufacturing. They are preferred over other types of valves because they offer several advantages, including:

- Low Maintenance: Rotary valves have a simple design and few moving parts, which makes them easy to maintain and repair.

- High Durability: Rotary valves are made from materials that are resistant to corrosion and wear, which makes them durable and long-lasting.

- Accurate Flow Control: Rotary valves offer precise control over the flow of fluids or gases, which makes them suitable for applications that require accurate dosing or metering.

- Easy to Clean: Rotary valves are easy to clean and sterilize, which makes them suitable for use in sanitary applications.

Overall, rotary valves are a reliable and cost-effective way to control the flow of fluids or gases in industrial applications

Rotary Selector Valve Operation:

The RSV can be operated in a clockwise or counterclockwise direction.

As the rotor passes each port a spring-loaded wiper is engaged against the valve body to seal the seating surface. This creates a self-cleaning action and removes accumulated debris that might restrict proper operation. It also increases the life of the port seal and valve body.

An adjustable, spring-loaded Carbon Teflon Port Seal serves as a soft seal that prevents leakage at the test line and valve body junction. Back-up rings located on the port seal are designed to accommodate excess pressure, higher temperatures, or chemical presence.

- Bidirectional Rotation

- Self Cleaning

- Self Sealing

- Adjustable Sealing Surface

- Back-Up Rings Improve Performance Life

- Improved and Revised Metallurgy for Longer Life and Advanced Product Performance

- Improved Elastomers and Seat Design to Meet Today’s Rugged Standards and Applications

Port Selection and Flow:

The Port Seal can be adjusted with a specially designed tool. The tool has two retractable spring-loaded pins that engage and disengaged via a pistol grip trigger. Each pin fits into a slot located on either side of the adjusting nut.

Specially designed O-Rings prevent external leakage through the valve body or head.

Emergency shutdown facilities; shut down upstream inlet ports in a single or group.

The downstream control valve can be remotely and automatically connected to the upstream setting point based on user requirements. The control system can be operated locally or remotely.

Optional quick disconnect fittings at all inlet/outlet flanges allow simple removal or relocation of the skid.

Special coatings for offshore or extreme conditions.

DESIGN CRITERIA:

- ASME B16.34 (American Society of Mechanical Engineers)

- ASME Sec. VIII, Div. 1 / Div. 2 (FCI- Fluid Control Institute)

- ASME B16.5 (FCC-Fluid Catalytic Cracking)

- NACE MR 0175 / ISO 15156 (National Association of Corrosion Engineers)

- API 598 (American Petroleum Institute)

- ANSI/FCI 70-2-2006 (American National Standards Institute)

- MSS SP-55 (Manufacturers Standardization Society)

- FEA Analysis, Proper Safety Factors, Industry/Local Required Codes

- ASME VIII Division 1 Design Criteria

ANSYS finite element analysis software is employed for the main components of the RSV. Working and test conditions are analyzed and utilization factors (safety factors) to code allowable are verified.

A standard approach is to utilize the ASME VIII Division 1 design criteria and always employ the casting quality factor unless the design is unique, limited in quantity, and customized for specific applications.

Improvements to the RSV continue as the needs of the client base require with respect to metallurgy, flow, line-pigging characteristics, valve size, pressure classes, seals, differentials, controllers, communication protocols, and serviceability, metering capabilities, spill prevention or containment.

Additionally, we are faced with the task of ensuring each design supports ergonomic operation, safety, simplified integration, and environmental protection from leakages, such as H²S fluids or gas.

Simplified Design – 3 Main Parts:

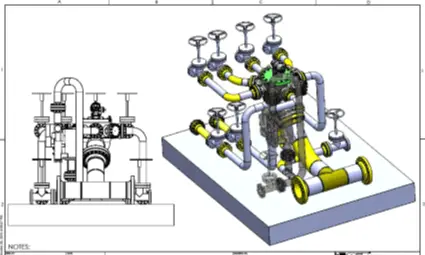

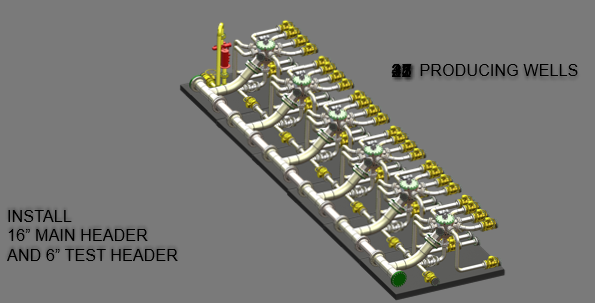

Skid Design:

Based on the results of the analysis conducted using FEA, the Sled meets the requirements of AISC with a safety factor greater than 1.5 for all loading conditions and a safety factor greater than 3 for the Lifting Eyes.

The multiport modular skid system utilizes a simple, design that saves time, money, and human resources. The system accommodates quick connect expandability for future field growth or quick disconnect to move those resources to other areas for improved utilization.

New Designs Based On Customer Requirements:

- ANSI CL 1500 – 2500

- SAG-D – Extreme Temperature

- Full Body Alloy

- Custom Skid – GA/Design

RSV SKIDS WITH A SINGLE FLOW METER:

MULTIPHASE FLOW METER

A multiphase flowmeter is a device used in the oil and gas industry to measure the flow rates of a mixture of oil, gas, and water in pipelines. As the name suggests, it can measure multiple phases of a fluid flow simultaneously, which is important because, in many applications, the fluid stream is not homogeneous and can contain different types of fluids.

A multiphase flowmeter typically uses a combination of different technologies to measure the different phases of the flow, such as ultrasonic sensors, gamma-ray detectors, and differential pressure sensors. These measurements are then combined to calculate the flow rates of the individual phases.

Multiphase flowmeters are especially useful in offshore oil and gas production, where it is difficult and expensive to separate the oil, gas, and water before they are transported to shore. By accurately measuring the multiphase flow, operators can optimize production, reduce costs, and ensure compliance with regulatory requirements.

How does a Multiphase Flowmeter work?

The permanent multiphase flow meter (MPFM) uses technology for continuous flow rate measurements. The Typical Multi-Phase Flow Meter operates equally well in both oil and dry gas environments, making it possible to monitor and test dry gas, condensate, and oil wells with a single meter.

Via a remote data link to the multiphase meter, users can validate well data, perform quality control, generate well test reports, analyze well data, diagnose production, and interpret reservoir intervals. By eliminating the need for separators and their associated support systems or controls, the system is ideal for both Onshore and Offshore Applications, satellite, or unmanned locations, including subsea installations.

Since the need for a separator has been eliminated, the requirements for space, load, and maintenance are reduced. Continuous, highly accurate flow rate measurements allow for quicker response time to production anomalies. The typical MPFM has limited or no moving parts and is essentially maintenance-free. Remote monitoring increases the safety of field personnel and allows for better utilization of human resources.

Multiphase flowmeters (MPFM) work by measuring the different phases of a fluid flow, typically a mixture of oil, gas, and water, using a combination of different sensors and technologies. Here is a general overview of how an MPFM works:

- Sensor Configuration: An MPFM typically consists of a combination of sensors that are placed in the flowline, including gamma-ray densitometers, ultrasonic sensors, and pressure transducers. Each sensor measures a different property of the fluid, such as density, velocity, and pressure.

- Data Acquisition: The sensors are connected to a data acquisition system that collects the data from each sensor and processes it in real time.

- Multiphase Flow Model: The data is then fed into a multiphase flow model, which uses algorithms and mathematical models to calculate the flow rates and properties of each phase of the fluid.

- Output: The output from the MPFM can be displayed on a control panel or sent to a computer for further analysis. The information can be used to monitor the flow rates, the ratio of oil, gas, and water, and other important parameters.

Overall, the MPFM provides an accurate and reliable way to measure the flow of multiphase fluids, which is essential for optimizing production, monitoring the performance of wells and pipelines, and ensuring compliance with regulatory requirements.

Applications of MPFM

Multiphase flowmeters (MPFM) have a wide range of applications in the oil and gas industry, particularly in the upstream sector where they are used for the well testing and production monitoring. Here are some of the main applications of MPFM:

- Well Testing: MPFM is used during the initial phase of well testing to determine the flow rates and characteristics of the fluids produced from a well. This information is used to optimize the production and recovery of oil and gas from the reservoir.

- Production Monitoring: MPFM is used to monitor the production of oil and gas wells over time. This information is used to optimize the production process and to identify problems such as sand production, scale buildup, and water breakthrough.

- Allocation Measurement: MPFM is used to measure the amount of oil, gas, and water produced from individual wells or fields. This information is used to allocate the production between different partners or to determine the royalties owed to the government.

- Pipeline Monitoring: MPFM is used to monitor the flow of oil and gas through pipelines. This information is used to optimize pipeline operation and to identify problems such as pipeline corrosion, blockages, and leaks.

- Reservoir Management: MPFM is used to monitor the behavior of reservoirs over time. This information is used to optimize the production process and to identify opportunities for enhanced oil recovery.

Overall, MPFM is a key technology in the oil and gas industry, allowing operators to accurately measure the flow of multiphase fluids and optimize production while minimizing costs and environmental impact.

Types of Multiphase Flowmeters

There are several types of multiphase flowmeters (MPFM) available in the market, each using different technologies and methods for measuring the flow rates of a multiphase fluid. Here are some of the most common types of MPFM:

- Gamma Ray Densitometer (GRD): GRD uses gamma rays to measure the density of the fluid, which is then used to calculate the volumetric flow rate. This method is suitable for fluids with varying densities.

- Venturi Meter: A Venturi meter is a type of differential pressure flowmeter that uses a constriction in the flowline to create a pressure drop. The difference in pressure is used to calculate the flow rate of the fluid. This method is suitable for low gas-liquid ratios.

- Ultrasonic Flowmeter: An ultrasonic flowmeter uses sound waves to measure the velocity of the fluid. The transit time of the sound waves is used to calculate the flow rate of the fluid. This method is suitable for low liquid-liquid ratios.

- Coriolis Flowmeter: A Coriolis flowmeter measures the mass flow rate of the fluid by detecting the Coriolis force that is generated by the fluid as it flows through a vibrating tube. This method is suitable for fluids with varying densities and viscosities.

- Magnetic Flowmeter: A magnetic flowmeter measures the volume flow rate of a conductive fluid by inducing a magnetic field in the flowline and measuring the voltage generated by the flow of the fluid. This method is suitable for fluids with low conductivity.

- Phase Doppler Anemometry (PDA): PDA is a laser-based method that measures the velocity of particles in the fluid flow. The velocity data is used to determine the flow rate and the size distribution of the particles in the fluid.

Overall, the choice of MPFM depends on the characteristics of the fluid being measured and the specific application requirements.

Multiphase Flow Meter Manufacturers

There are several reputed manufacturers of multiphase flowmeters (MPFM) in the market. Here are some of the top manufacturers:

- Emerson Electric Co.: Emerson Electric Co. is a global technology company that offers a range of MPFM products, including Coriolis, ultrasonic, and gamma-ray densitometer flowmeters.

- Schlumberger Limited: Schlumberger Limited is a leading oilfield services company that offers a range of MPFM products, including ultrasonic and gamma-ray densitometer flowmeters.

- Weatherford International plc: Weatherford International plc is a multinational oilfield service company that offers a range of MPFM products, including ultrasonic and gamma-ray densitometer flowmeters.

- ABB Ltd.: ABB Ltd. is a Swiss multinational company that offers a range of MPFM products, including Coriolis, ultrasonic, and magnetic flowmeters.

- TechnipFMC plc: TechnipFMC plc is a global engineering and construction company that offers a range of MPFM products, including ultrasonic and gamma-ray densitometer flowmeters.

- Krohne AG: Krohne AG is a German company that offers a range of MPFM products, including Coriolis, ultrasonic, and magnetic flowmeters.

- Cameron International Corporation: Cameron International Corporation is a leading manufacturer of flow equipment, including MPFM products such as gamma-ray densitometer flowmeters.

These manufacturers have a long-standing reputation for quality and reliability and are widely used by the oil and gas industry for various applications.

Flow Characteristics:

- The RSV can be operated in a clockwise or counterclockwise direction.

- As the rotor passes each port a spring-loaded wiper is engaged against the valve body to seal the seating surface. This creates a self-cleaning action and removes accumulated debris that might restrict proper operation. It also increases the life of the port seal and valve body.

- An adjustable, spring-loaded Carbon Teflon Port Seal serves as a soft seal that prevents leakage at the test line and valve body junction. Back-up rings located on the port seal are designed to accommodate excess pressure, higher temperatures, or chemical presence.

CONCLUSION:

The RSV Multiport Skid provides a simple, cost-effective solution to manifold fluids in low maintenance, environmentally friendly package. The compact design reduces capital costs and allows for better utilization of resources when and where they are needed. The latest data communication technologies provide continuous feedback to help maintain a high level of operational efficiency and ensure quicker response time to production anomalies.