Annealing is one of the most popular heat treatment methods to alter the mechanical properties of metals and alloys. Annealing is mostly used to increase the ductility of a material and to reduce the hardness. After annealing treatment, the metals or alloys become more workable. In this article, we will discuss the annealing process in detail.

What Is Annealing?

Annealing is a heat treatment process in which a metal is heated above its recrystallization temperature, kept at that temperature for some time for homogenization, and then cooled slowly to develop an equilibrium structure. In the crystal structure of the metal or alloy being annealed, the number of dislocations is reduced which causes an increase in ductility and relief of residual stresses. Usually for materials that have undergone some cold work or hardening treatment annealing is performed. So the main purposes of an annealing heat treatment are:

- To eliminate internal residual stresses that occurred during earlier processing steps.

- To improve the machinability of the metal.

- To increase ductility which in turn improves formability.

- To prevent deformation and cracking.

- To reduce hardness and increase toughness.

- To improve magnetic properties and decrease electrical resistance.

- To refine the grain size.

- To reduce the gaseous contents of the metal or alloy.

Stages of the Annealing Process

Every annealing heat treatment process consists of three stages; the Recovery stage, the Recrystallization stage, and the Grain growth stage. These stages work as follows:

Recovery Stage: In the recovery stage of the annealing process, the metal is heated in a furnace and its temperature is raised to such a point where the internal stresses are relieved.

Recrystallization Stage: In this stage, the metal is heated above the recrystallization temperature where new grains form without any residual stresses. Recrystallization is defined as a process where the deformed grains in a metallic structure are replaced by a new set of defect-free grains at a certain specific temperature range known as the recrystallization temperature.

Grain Growth Stage: In this stage of the annealing process, the material is cooled at a pre-decided rate for new grains to fully develop.

Metals for Annealing Treatment

The annealing process is applicable for most of the common materials like Steel, Cast Iron, Aluminum, brass, copper, etc. However, the material selected should be such that its properties can be altered by heat treatment. The majority of the annealing process is done over the steel alloy. All work-hardened steel materials like sheet metals, wires, and welding processes creating high residual stresses must undergo the annealing of steel processes to recover their properties.

What is Annealing Steel and its Types

Annealing steel means heating it to a predetermined temperature, holding it at that temperature for a certain period of time, and finally cooling at a very slow rate. The temperature to which the steel should be heated and the holding time are determined considering various factors like

- Chemical composition of the steel (%Carbon content)

- Shape and size of steel component( thickness)

- Final properties desired.

Depending on the temperature of annealing treatment, phase transformation, and purpose, the annealing of steel is classified into various groups.

Steel Annealing types based on annealing temperature

Considering the steel annealing temperature, the annealing process is sub-divided into three classes. They are

- Full Annealing

- Partial annealing, and

- Sub-critical annealing

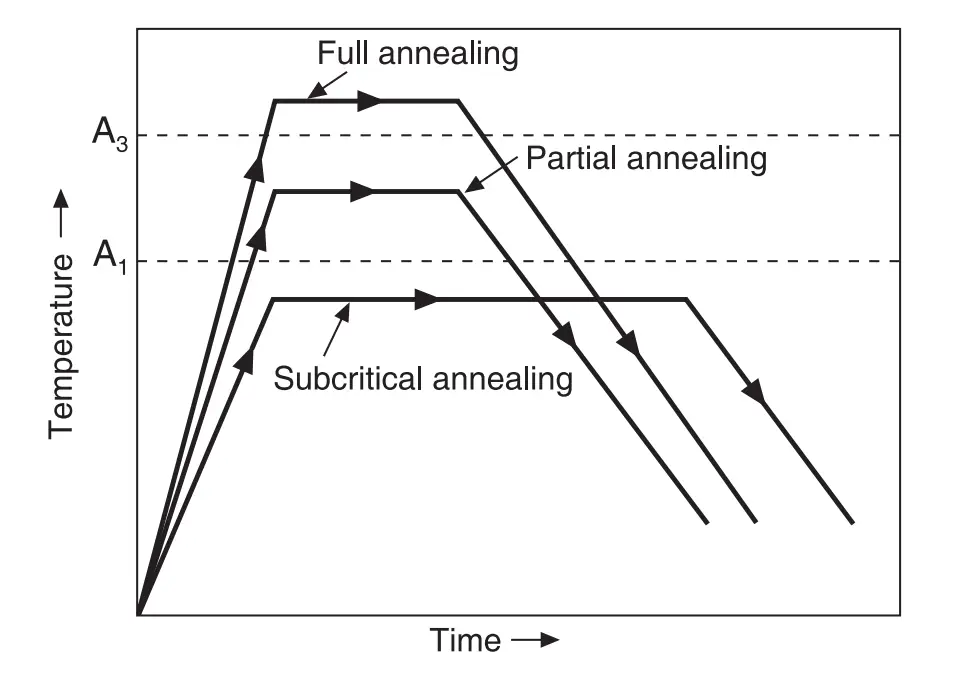

Refer to Fig. 1 below that shows the temperatures at which Steel alloy should be heated for the above-mentioned annealing processes.

As understood from the above figure, in the full annealing process, steel is heated above the upper critical temperature (A3) and then cooled very slowly. In the case of partial annealing, steel is heated to a temperature that lies between lower (A1) and upper (A3 or Acm) critical temperature and then cooled slowly. Partial annealing is also known as inter-critical annealing or incomplete annealing. For the subcritical annealing process, the steel is heated below the lower critical temperature (A1). No phase change takes place in subcritical annealing and thus only recrystallization, softening, recovery, and grain growth occur.

Annealing Steel types based on specific purposes

Based on the specific purposes of annealing steel, the process is grouped into various types. They are:

- Diffusion Annealing

- Full Annealing

- Spheroidizing Annealing

- Recrystallization Annealing

- Isothermal Annealing

- Process Annealing

Full Annealing of Steel

Full annealing of steel is also known as phase recrystallization annealing. This process ensures the refinement of grains and the elimination of structural inhomogeneity. The process of full annealing of steel consists of heating the steel alloy to 30 to 500C above (A3 for hypo-eutectoid steels, A1 for eutectoid steel) followed by slow cooling. Almost all castings, forgings, and rolled stocks are provided with this treatment to get enhanced mechanical properties.

Diffusion Annealing of Steel

The purpose of diffusion annealing is to eliminate inhomogeneities of the chemical composition, dendrites, and columnar grains which appear during the crystallization of alloys. Diffusion annealing is usually carried out at a temperature of 1100–13000C (2012–23720F) and then the steel is held at this temperature for 10-20 hours, followed by slow cooling. Diffusion annealing is used to smooth out a difference in the content of alloying elements due to the inter-crystal liquation and chemically homogeneous steel is obtained. To improve the properties of medium-purity steels, this type of annealing is used.

Isothermal Annealing of Steel

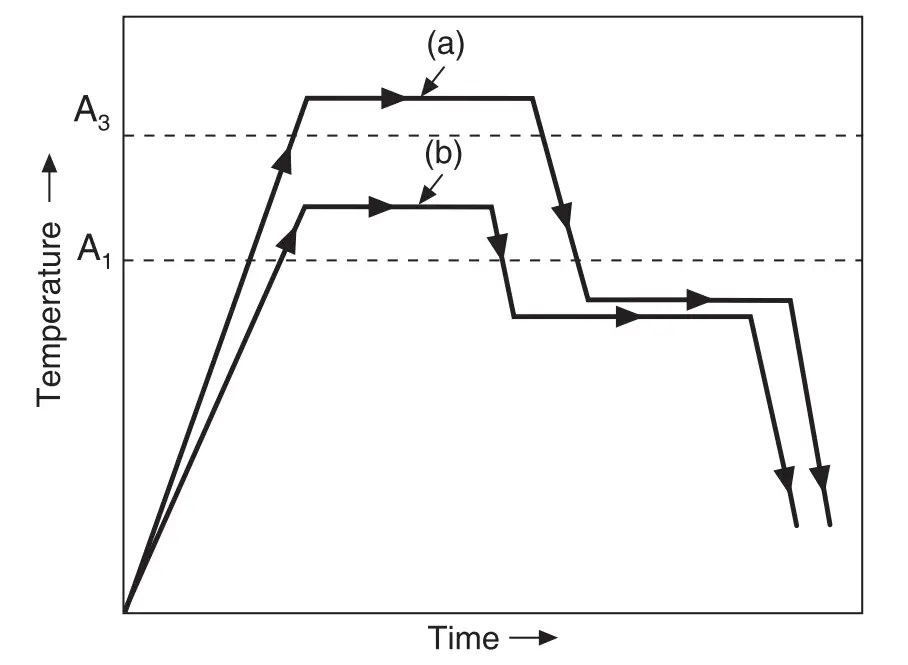

In isothermal annealing, after heating the steel to above critical temperatures is held at this temperature for quite some time. It is then rapidly cool to 600-7000C by rapidly transferring the steel to another furnace maintained at the desired temperature. This temperature is maintained for some time and then cooled in the air. This process improves machinability and a better surface finish during machining. The heat treatment cycle is shown in Fig. 2

Recrystallization Annealing of Steel

To increase the ductility of cold-worked steels, recrystallization annealing is used. The temperature at which the steel is to be heated depends on the amount of prior deformation, chemical composition, holding time, and initial grain size. Usually, alloy steels and high carbon steels require a higher temperature.

Process Annealing of Steel

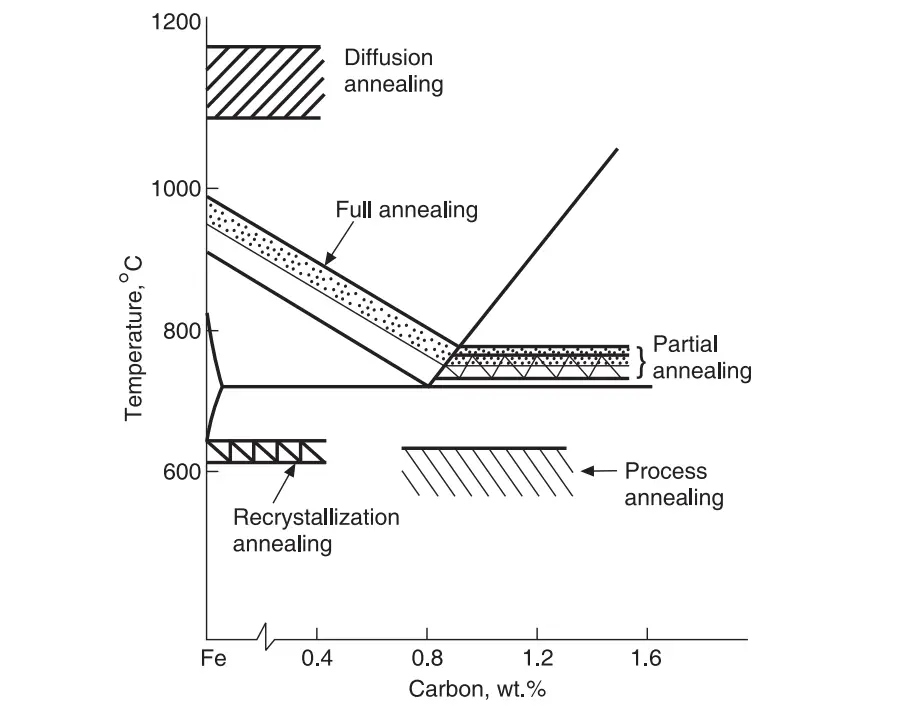

Process annealing of steel consists of heating it below A1 temperature and holding it at this temperature for sufficient time and then cooling it. It is usually an intermediate operation for processing the steel further. Process annealing treatment is widely given for steel fabricated by extrusion, stamping, upsetting, and drawing. The temperatures at which steel should be heated for various annealing treatments are provided in Fig. 3 below:

Spheroidizing Annealing of Steel

Spheroidizing annealing results in carbide spheroids in a ferrite matrix. The degree of spheroidization varies according to heat-treatment temperature and holding time. Various processes are available to get spheroid structures in steel. To improve machinability and ductility, Spheroidizing Annealing is often performed for alloy steels and high carbon steels.

Does annealing increase strength?

Yes, the annealing treatment of metals increases the strength by reducing dislocation sources. The annealing process improves the ductility of material by strengthening grain boundaries’ resistance to intergranular cracks.

Do you quench after annealing?

For annealing of steel, the cooling method applied is slow cooling, not immediate. So, in general, steel is not quenched after annealing.

What are the types of annealing?

The annealing process can be categorized into several types:

- Complete Annealing.

- Partial Annealing

- Isothermal Annealing.

- Spherical Annealing.

- Recrystallization Annealing.

- Diffusion Annealing.

- Stress Relief Annealing.

What industries use annealing?

Manufacturing industries dealing with Steel, Cast Iron, Aluminum, Copper, Brass, etc use the annealing process widely. Usually, materials are annealed before extreme forming or drawing operations.

Annealing sounds like a really useful process to make metals have even more flexibility. The fact that it can be used to improve its machinability and toughness is really helpful for those working in the fabrication industry and the like. I can definitely see how it can be used in places such as factories and fabrications and would make use of such a method.

Dear anup,

Please advise which type of steel I should buy to manufacture HR tubes and Pipes. anneal steel or unannealed steel.