In the world of industrial storage tanks, ensuring the safety and integrity of aboveground storage tanks is of paramount importance. API 650, developed and published by the American Petroleum Institute (API), is a widely recognized standard that governs the design, fabrication, and installation of welded steel tanks for various liquid storage applications. This blog article aims to provide a comprehensive overview of API 650 and its significance in the storage tank industry.

History and Purpose of API 650

API 650 was first issued in 1961 by the American Petroleum Institute to address the need for consistent design and construction practices for aboveground storage tanks storing petroleum products and other liquid commodities. Over the years, the standard has undergone several revisions and updates to incorporate new technologies, improve safety, and reflect best industry practices.

The primary purpose of API 650 is to ensure the safe and efficient storage of liquids with specific attention to environmental protection, tank durability, and the prevention of catastrophic failures. While writing this article, the latest edition of API 650 is the 13th edition published on March 2020.

Scope of API 650

API 650 applies to the design and construction of welded storage tanks with a capacity greater than 119 gallons (450 liters) and operating at atmospheric pressure. The standard covers a wide range of tank configurations, including:

- Aboveground, cylindrical, and non-refrigerated tanks.

- Tanks with internal pressures not exceeding the weight of the roof. The maximum internal design pressure is limited by 18 KPa.

- Tanks with a maximum operating temperature of 200°F (93°C).

- Tanks are designed to store liquids with various properties, such as water, crude oil, chemicals, and more.

- Tanks whose entire bottom is supported uniformly.

Design and Engineering Requirements

API 650 provides comprehensive guidelines for the design and engineering of aboveground storage tanks. Key aspects covered include:

- Material Selection: The standard mandates the use of carbon or low-alloy steel that conforms to specific mechanical properties to ensure tank integrity.

- Shell Design: API 650 outlines the methods for calculating the required shell thickness based on factors such as tank diameter, product storage, environmental conditions, and seismic loads.

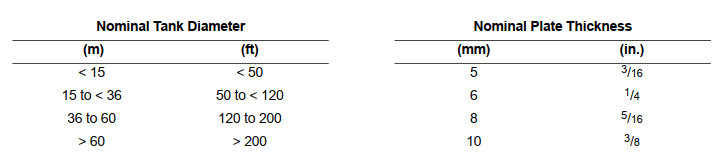

- The shell thickness is calculated as the greater of the design shell thickness, including any corrosion allowance, or the hydrostatic test shell thickness. However, there is a limitation of minimum shell thickness with respect to size as given in Fig. 1. (shall not be less than the given values in the table). There are three methods by which the tank shell thickness is usually calculated; the 1-foot method, the variable design point method, or the elastic analysis method.

- Roof and Bottom Design: The standard details various roof and bottom configurations, including cone, dome, and umbrella, with specific design considerations for each.

- Wind and Seismic Design: API 650 incorporates wind and seismic design criteria to ensure tanks can withstand external forces without failure.

- Anchorage Design: Tanks must be anchored to prevent uplift during high wind or seismic events.

Fabrication and Construction

The fabrication and construction of tanks under API 650 are critical to ensuring long-term integrity. The standard provides guidance on welding procedures, non-destructive testing, and inspection during construction to maintain quality and compliance.

Inspection, Examination, and Testing

API 650 emphasizes the importance of periodic inspections, examinations, and testing to assess the tank’s condition throughout its service life. These activities help identify and address potential issues before they become critical.

Repairs, Alterations, and Reconstruction

API 650 also addresses the repair, alteration, and reconstruction of existing tanks. It outlines the necessary steps to safely modify or renovate tanks to meet current standards while preserving their structural integrity.

What is Annex P of API 650?

Annex P of API 650 is very important to Pipe Stress Engineers as this annex presents two different procedures for determining external loads on tank shells. This Annex is used for tanks larger

than 36 m (120 ft) in diameter. For tanks 36 m (120 ft) in diameter and smaller, this annex will be applicable only when specified by the Purchaser. Annex P2 creates a nomogram boundary condition to inform if the external piping loads (Radial force, Fr and Longitudinal and Circumferential Moment, Ml and Mc) are acceptable. Annex P3 provides an alternative method for the evaluation of external loads on tank shell openings using WRC 297/ASME Sec VIII Div 2/FEA.

API Standard 650 Storage Tank Data Sheet

API 650, the standard for aboveground storage tanks, provides guidelines for the information that should be included in a datasheet for the design of welded steel storage tanks. The data sheet serves as a comprehensive document that helps ensure consistent design, fabrication, and inspection practices. Below is a list of key information that should be furnished in a datasheet according to API 650:

- General Information:

- Project title and location.

- Name of the tank owner or operator.

- Name of the tank designer or engineering firm.

- Date of preparation of the datasheet.

- Reference to the applicable edition of API 650.

- Tank Design Data:

- Design conditions, including maximum and minimum design temperatures and pressures.

- Product properties, such as specific gravity, vapor pressure, and corrosiveness.

- Tank capacity (volume) in barrels or cubic meters.

- Tank diameter and height (or other dimensions).

- Seismic design criteria, wind loads, and other external forces.

- Material Specifications:

- Material specifications for the shell, roof, bottom, and other tank components.

- Material mechanical properties, including yield strength and tensile strength.

- Corrosion allowances and considerations.

- Shell Design Information:

- Design methods used for calculating shell thickness (e.g., 1-foot method or variable design point method).

- Wind girders or wind stiffeners details if applicable.

- Seismic design details and parameters.

- Roof Design Information:

- Roof type and design (e.g., cone, dome, umbrella, floating).

- Roof live load requirements.

- Roof support details, including columns, rafters, and girders.

- Bottom Design Information:

- Bottom type and design (e.g., flat, sloped, conical).

- Bottom plate layout and details.

- Annular ring and ringwall design if applicable.

- Welding and Fabrication:

- Welding procedures and specifications.

- Details about non-destructive testing (NDT) methods, such as radiographic or ultrasonic testing.

- Quality control and inspection requirements during fabrication.

- Corrosion Protection:

- Coating and lining specifications for interior and exterior surfaces.

- Cathodic protection details if required.

- Anchorage and Foundation:

- Tank anchorage design and details.

- Foundation design and specifications.

- Accessories and Appurtenances:

- Details about vents, nozzles, manways, platforms, ladders, and other tank accessories.

- Inspection and Testing:

- Inspection and testing requirements during and after fabrication.

- Radiographic or ultrasonic testing procedures and acceptance criteria.

- Hydrostatic testing details.

- Repairs and Alterations:

- Procedures for repairs, alterations, and modifications to the tank after construction.

- Guidelines for maintaining structural integrity during modifications.

- Documentation and Drawings:

- List of documents and drawings included with the datasheet.

- Tank drawings, including plan views, elevation views, and details.

API 650 vs. API 620

While API 650 is specifically designed for atmospheric storage tanks, other standards like API 620 cater to the design and construction of low-pressure storage tanks with more complex design requirements. Understanding the differences between these standards is crucial when selecting the appropriate standard for specific projects. Click here to learn the major differences between API 650 and API 620.

Conclusion

API 650 is a cornerstone of aboveground storage tank design and construction, providing essential guidelines to ensure the safety, environmental protection, and durability of these critical assets. Compliance with this standard not only ensures the safe storage of liquids but also helps build trust among regulatory agencies and the public.

As technology and industry best practices evolve, the API 650 standard continues to be updated to incorporate the latest advancements, making it a reliable and indispensable tool for professionals in the storage tank industry. By adhering to API 650, companies can mitigate potential risks, minimize environmental impact, and protect their investments in liquid storage infrastructure.

Sirs, Kindly share API 650 hydrostatic checklist and data sheet.