Ductile iron is a special type of cast iron having properties comparable to steel. Also known as ductile cast iron, spheroidal graphite iron, spheroidal graphite cast iron, nodular cast iron, or SG iron, Ductile iron is an alloy of iron and carbon in graphite form. In the year 1943, ductile iron was first developed by Keith Millis in the International Nickel Company Research Laboratory. As the name suggests, this material has ductile characteristics while other varieties of cast iron are brittle in nature.

Due to its unique microstructure, ductile iron exhibits high strength, durability, flexibility, and elasticity. It has mechanical properties comparable to steel.

Metallurgy of Ductile Iron

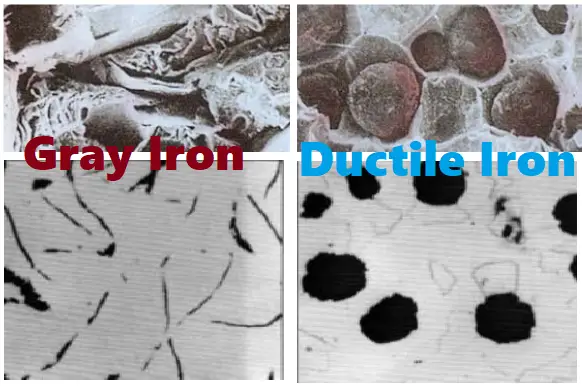

The shape of graphite in the microstructure is the main defining characteristic of ductile iron. In ductile iron, the graphites are present in nodular or spheroidal form (Fig. 1) which increases the ductility of the material. Various nodulizing elements like magnesium, ferrosilicon, cerium, tellurium, etc are added to form those nodular graphites in ductile iron.

Ductile Iron Composition

Usually, ductile iron is composed of 3.2 to 3.6% Carbon, 2.2 to 2.8% Silicon, 0.1 to 0.2% Manganese, 0.03 to 0.04% Magnesium, 0.005 to 0.04% Phosphorus, 0.005 to 0.02% Sulfur, Less than 0.4% Copper and Remaining (Around 94%) Iron. Additionally, tin or copper can be added to increase the strength of ductile iron at the expense of ductility. By adding chromium and nickel, the corrosion resistance of ductile iron can be improved. Also, to provide better oxidation protection Aluminum can be added replacing Silicon.

Types of Ductile iron

Through microstructural control, a range of properties are achieved and accordingly various types of ductile iron are available for industrial applications. they are:

- Ferritic Ductile Iron: Ferritic ductile iron consists of graphite nodules in a ferrite matrix. This type of ductile iron provides good ductility, and impact resistance, with tensile and yield strength comparable to low-carbon steel.

- Ferritic Pearlitic Ductile Iron: The microstructure contains the graphite spheroids in a matrix containing both ferrite and pearlite. Ferritic Pearlitic Ductile Iron exhibits properties intermediate between ferritic and pearlitic grades. They have good machinability and low production costs.

- Pearlitic Ductile Iron: Pearlite matrix in the microstructural characterization of this category of ductile iron. They provide good machinability, high strength, good wear resistance, moderate ductility, and impact resistance.

The above types of ductile irons are used in the as-cast condition. Additional ductile iron grades to meet a variety of application requirements can be produced by alloying and heat treatment. Accordingly, the following ductile iron grades are widely used:

- Martensitic Ductile Iron: This type of Ductile Iron is produced by quench-and-temper heat treatment, preventing pearlite formation. Martensitic ductile iron possesses very high strength and wear resistance but with lower levels of ductility and toughness.

- Bainitic Ductile Iron: It is a very hard and wear-resistant grade ductile iron material.

- Austenitic Ductile Iron: The austenitic matrix of this Ductile Iron provides good corrosion and oxidation resistance, good magnetic properties, strength, and dimensional stability at elevated temperatures.

- Austempered Ductile Iron (ADI): This is the most recent addition to the Ductile Iron family. Special austempering heat treatment produces ADI which is twice as strong as pearlitic Ductile Iron. Also, it possesses high elongation, toughness, wear resistance, and fatigue strength.

Properties of Ductile Iron

Ductile iron shows increased properties as compared to other cast iron families. It increases the resistance to breakage against physical loads or shocks and thus increases the safety and reliability of the ductile iron parts. The main physical and mechanical properties of ductile iron are provided below:

| Physical Properties | Ductile Iron |

| Density | 7100 Kg/m3 |

| Co-efficient of Thermal Expansion | 12.3X10-6 cm/cm/0C |

| Mechanical properties | Ductile Iron |

| Tensile Strength | 414 MPa to 1380 MPa |

| Yield Strength | 275 MPa to 620 MPa |

| Young’s Modulus | 162-186 MPa |

| Poisson’s Ratio | 0.275 |

| Elongation | 18% to 35% |

| Brinell Hardness | 143-187 |

| Charpy unnotched impact strength | 81.5 -156 Joules |

Other properties of ductile iron include:

- Good fatigue strength

- Very good castability

- Good machinability

- Good compressive strength

- Excellent strength-to-weight ratio

- Suitable for large and complex shapes

Applications of Ductile Iron

Even though ductile iron possesses comparable properties similar to cast steel, it is quite cheaper than steel. Properties like high yield strength, wear resistance, ductility, pressure tightness, impact resistance, heat resistance, corrosion resistance, etc. make ductile iron an ideal choice for various engineering applications. A sample list of products/components where ductile iron is found to be used extensively are:

- Pipe and pipe fittings. More than 50% of ductile iron is used in the manufacturing of ductile iron pipes and fittings to convey various fluids.

- Crankshafts, Connecting rods in the Automobile industry

- Cylinders

- Gears and Gear Boxes

- Disc brake calipers

- Housings and manifolds

- Hydrostatic Barrels

- Large Machines

- Idler’s arms

- Pump Housing

- Military uses

- Machine Tooling

- Piano Harps

- Suspension system parts

- Spindle supports

- Steering knuckles

- Yokes for power transmission

- Truck axles

- High-pressure Valves

- Wheel hubs

- Oil well pumps

- Agricultural tractors

- Wheels

- Cable Drums

- Gas Turbine Casing

- Air Compressor Block and Crankcase

- Backhoe Loader Swing Pivot and Stabilizer Foot

ASTM Specifications of Ductile Iron Castings

Five ASTM specifications cover the ductile iron castings. Out of those five, ASTM A 536 is the most widely used specification that covers the general engineering grades of ductile iron while austenitic and special grades are covered in other specifications. The following list will provide the ASTM standards that cover ductile irons:

- ASTM A395 covers Ferritic Ductile Iron Pressure-Retaining Castings

- ASTM A439 covers Austenitic Ductile Iron Castings

- ASTM A476 covers Ductile Iron Castings for Paper Mill Dryer Rolls

- ASTM A536 covers Specifications for Ductile Iron Castings

- ASTM A571 covers Austenitic Ductile Iron Castings for Pressure-Containing Parts Suitable for Low-Temperature Service

- ASTM A716 covers Ductile Iron Culvert Pipe

Ductile iron vs Cast iron: Differences between Ductile Iron and Cast Iron

So from the above discussions, it is now clear that Ductile iron is better as compared to cast iron or gray iron. The major differences between ductile iron and cast iron are provided below:

Ductile Iron vs Cast Iron-Ductility: As the name suggests ductile iron is ductile whereas cast iron is brittle. Hence, ductile iron does not break suddenly due to impact force. Cast iron does not allow it to bend whereas ductile iron behaves opposite to cast iron.

Cast Iron vs Ductile Iron-Microstructure: Ductile iron contains graphite in nodular form whereas cast iron has graphite flakes in the microstructure. These nodules increase the flexibility of ductile iron while reducing its hardness.

Ductile Iron vs Cast Iron-Cost: From an economic point of view, ductile iron is slightly more expensive than cast iron.

Cast Iron vs Ductile Iron-Physical and Mechanical Properties: Ductile iron has more tensile and yield strength, elongation, and greater resistance to impact while having lower thermal conductivity and vibration damping capability than gray iron. Ductile iron is more corrosion-resistant than gray iron.

Ductile Iron vs Steel: Differences between Carbon Steel and Ductile Iron

We mentioned earlier that Ductile iron has comparable properties to carbon steel. But there are many differences between carbon steel and ductile iron. Let’s have a look at the steel vs ductile iron differences.

Carbon Steel vs Ductile iron-Compositions: Carbon content in carbon steel (<2%) is less than that of ductile iron (>3%). Also, the carbon in ductile iron is in graphite form.

Ductile Iron vs Carbon Steel-Castability and Welding Characteristics: Carbon steel provides better weldability than ductile irons. However, Ductile iron has better castability as compared to carbon steel.

Carbon Steel vs Ductile iron-Impact and Shock Resistance: Carbon steel has better impact resistance. However, ductile iron has better shock and abrasion resistance capability than carbon steel. The corrosion resistance of ductile iron is superior to unalloyed carbon steel.

Ductile Iron vs Carbon Steel-Cost: The cost of Carbon steel is more than ductile iron.

A nice and comprehensive brief about SG Iron.

Useful for refreshing design engineers about material selection.