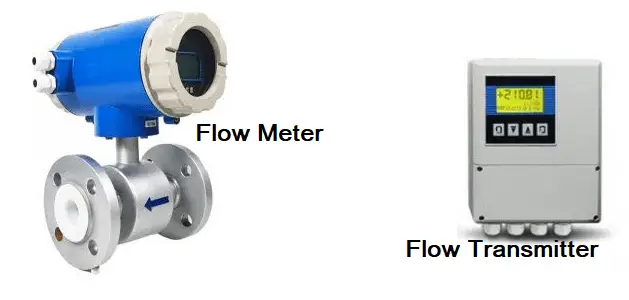

The accurate measurement and monitoring of fluid flow play a crucial role in ensuring efficiency, safety, and reliability in any process industry. Two essential devices employed for this purpose are flowmeters and flow transmitters. Although they serve interconnected roles in fluid flow measurement, they possess distinct functionalities and applications. In this guide, we will understand the disparities between flowmeters and flow transmitters, shedding light on their significance and divergent utilities across various industries.

What is a Flowmeter?

Flowmeters represent the frontline soldiers in the battle for precision in fluid dynamics. These instruments are engineered to directly measure the rate of flow within a conduit or pipeline, providing real-time insights into the movement of liquids or gases.

Their applications span across a multitude of industries, including oil and gas, water management, HVAC systems, chemical processing, and automotive sectors. In oil and gas exploration and production, for instance, flowmeters are instrumental in monitoring the volume and velocity of hydrocarbons during extraction and transportation. Similarly, in water management systems, flowmeters enable efficient distribution and conservation of water resources by precisely quantifying the flow rates within pipelines. Their importance cannot be overstated, as they serve as the eyes and ears of engineers and operators, guiding critical decisions and optimizations in industrial processes.

What is a Flow Transmitter?

Flow transmitters, on the other hand, operate behind the scenes, translating the language of flow dynamics into electrical signals comprehensible to monitoring systems and controllers. They play a pivotal role in facilitating automation, control, and data acquisition processes in industrial settings. Unlike flowmeters, which offer direct measurements, flow transmitters convert flow data into standardized electrical signals, such as voltage, current, or frequency.

Their versatility of flow transmitters makes them suitable for application in various industries, including manufacturing, chemical processing, water treatment, and pharmaceuticals. In chemical processing plants, for instance, flow transmitters enable precise regulation of fluid flow rates, ensuring optimal mixing, reaction kinetics, and product quality. Similarly, in pharmaceutical manufacturing, these devices play a critical role in maintaining stringent process control parameters, safeguarding product integrity, and compliance with regulatory standards. Despite their understated presence, flow transmitters serve as the backbone of modern industrial automation, enabling seamless communication and orchestration of complex processes. Fig. 1 shows a typical flow transmitter used in the oil and gas industry.

Flowmeter vs. Flow Transmitter: Differences

While both flowmeters and flow transmitters contribute to the flow measurement, they exhibit fundamental disparities in functionality, output signals, integration, and application domains. At their core, flowmeters are designed for direct measurement of flow rates, providing mechanical or digital readouts of fluid velocities. In contrast, flow transmitters serve as intermediaries, converting flow data into electrical signals for further processing and integration into control systems. The output signals generated by flow transmitters enable real-time monitoring, control, and data logging, facilitating optimization and decision-making in industrial processes. Furthermore, while flowmeters can operate as standalone devices, flow transmitters are typically integrated into larger control and monitoring systems, serving as vital components of industrial automation and process optimization initiatives.

Here are the main differences between the two:

Functionality:

- Flow Transmitter: A flow transmitter is primarily responsible for converting the physical parameters of flow into a standardized electrical signal, such as voltage, current, or frequency. It typically provides an output signal proportional to the flow rate, which can be used for monitoring, control, or data logging purposes.

- Flowmeter: A flowmeter, on the other hand, directly measures the flow rate of a fluid. It provides a direct indication of flow rate, often in units such as liters per minute (LPM) or gallons per minute (GPM), without necessarily providing an electrical output signal.

Output Signal:

- Flow Transmitter: It generates an electrical signal that represents the flow rate. This signal can be transmitted to other devices such as control systems, data loggers, or displays for further processing or visualization.

- Flowmeter: It typically provides a direct indication of the flow rate through mechanical means, such as a dial, a scale, or a digital display. Some flowmeters may also provide electrical output signals in addition to the direct indication.

Integration:

- Flow Transmitter: Often integrated into larger control or monitoring systems where the flow data is used for process control or automation.

- Flowmeter: These can be standalone devices or integrated into larger systems. They are often used in applications where direct, local measurement of flow rate is required without the need for integration into a control system.

Application:

- Flow Transmitter: Commonly used in industrial settings where precise measurement and control of flow rates are required for processes such as manufacturing, chemical processing, and water treatment.

- Flowmeter: Used in various applications across industries, including HVAC systems, oil and gas, water management, and automotive, where direct measurement of flow rate is needed.

here’s a table summarizing the differences between a flowmeter and a flow transmitter:

| Aspect | Flowmeter | Flow Transmitter |

|---|---|---|

| Measurement Function | Directly measures flow rate | Converts flow data into electrical signals |

| Output Signal | Often mechanical indication (e.g., dial) | Electrical signal (e.g., voltage, current) |

| Integration | Can be standalone or integrated | Typically integrated into larger systems |

| Application | Used for direct measurement of flow rate. In general, Flow meters are used in manual field applications. | Used for monitoring, control, or data logging. Flow transmitters can be operated remotely. |

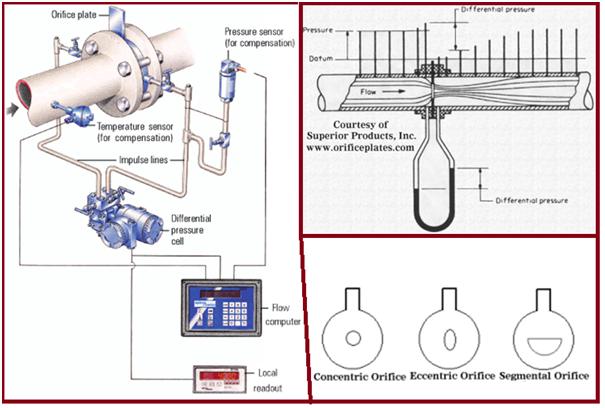

| Examples | Rotameter, turbine flowmeter, magnetic flowmeter | Differential pressure transmitter, electromagnetic flow transmitter |

| Industry Use | HVAC systems, oil & gas, water management, automotive | Industrial processes, chemical processing, water treatment |

Importance of Flowmeters and Flow Transmitters in the Oil and Gas Industry:

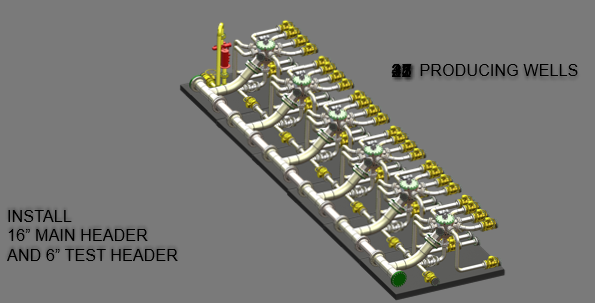

In the oil and gas industry, both flowmeters and flow transmitters assume critical roles in ensuring efficient exploration, extraction, transportation, and refining of hydrocarbons. Flowmeters are deployed at various stages of the production process, from wellheads to refineries, to accurately gauge the flow rates of crude oil, natural gas, and refined products. By providing real-time insights into flow dynamics, they enable operators to optimize production processes, minimize downtime, and enhance safety and environmental stewardship. Additionally, flow transmitters facilitate seamless communication and control across distributed networks of pipelines and processing facilities, enabling remote monitoring, diagnostics, and automation of critical operations. Together, these instruments form the backbone of operational excellence in the oil and gas sector, empowering stakeholders to navigate the complexities of fluid dynamics with precision and confidence.

Great Insights