How to use ASME B31J SIF and k-factors in PASS/START-PROF

For a long time, there was a need for a standard method to develop stress intensification factors (SIFs or i-factors) for ASME piping components and joints. At the time, the B31 Code books provided SIFs for various standard fittings and joints but did not provide guidance on how to conduct further research on existing SIFs or how to establish SIFs for nonstandard and other standard fittings or joints.

ASME B31J is the outcome of recent research by MDC on current manufacturing practices in the SIF and k-factor test procedures, to provide a consistent and up-to-date table of SIFs and k-factors for metallic piping components.

ASME B31J provides a standard approach for the development of SIFs, k-factors, and sustained stress multipliers for piping components and joints of all types, including standard, nonstandard, and proprietary fittings. However, this code still does not cover fittings that have a D/T ratio greater than 100 for which we have to be dependent on FEA analysis.

So in nutshell, The code ASME B31J-2017 offers us revised, more accurate SIFs and flexibility factors for tees, bends, and reducers. By using these revised SIFs and flexibilities, the pipe stress analysis results become more accurate.

Now the question is How to use it in START-PROF Software?

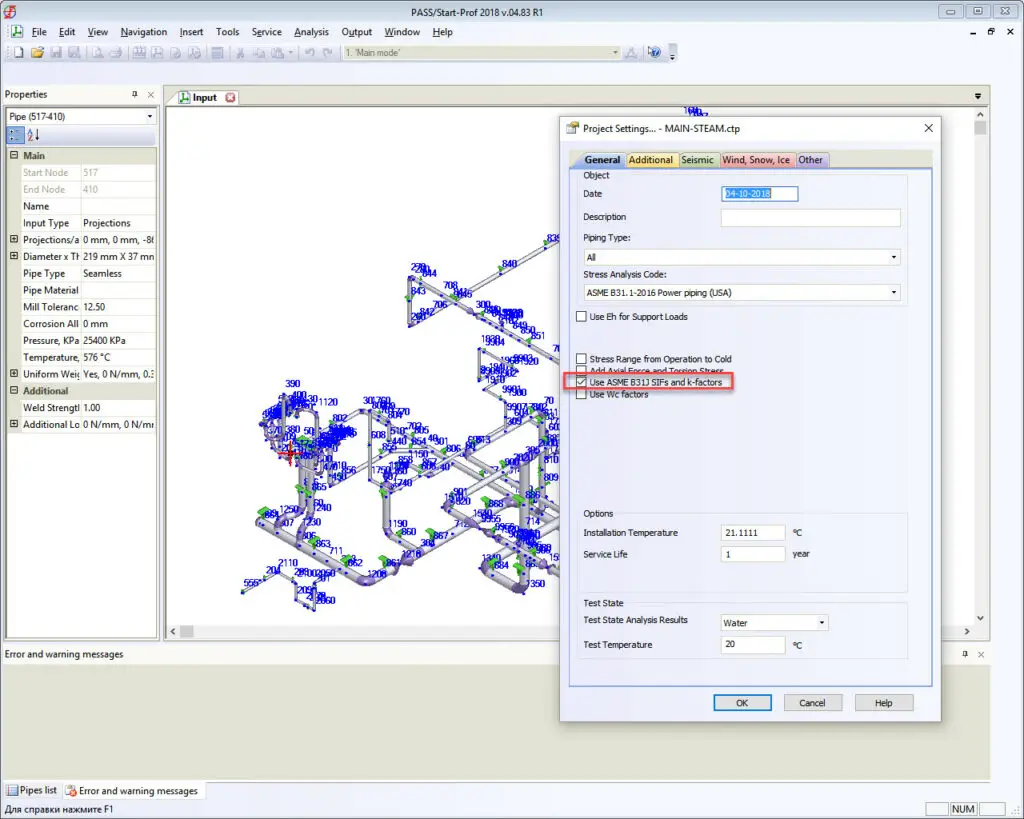

Very easy. No additional software or model conversion is needed. Just turn on this checkbox:

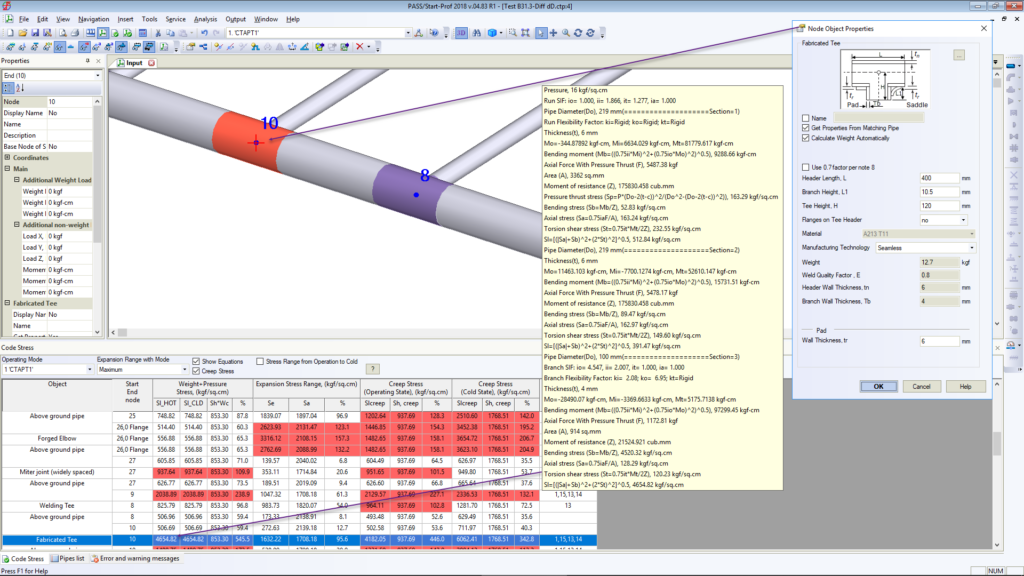

If the “ASME B31J” option is activated then all tees are automatically modeled with simultaneous use of run and branch springs with flexibilities and stress intensification factors calculated according to ASME B31J code requirement:

Start-Prof software allows activating “ASME B31J” option for ASME B31.1, B31.3, B31.4, B31.5, B31.8, B31.9 and EN 13480 codes. If some of the k-factor becomes less than 1.0 Start-Prof assumes this spring as rigid:

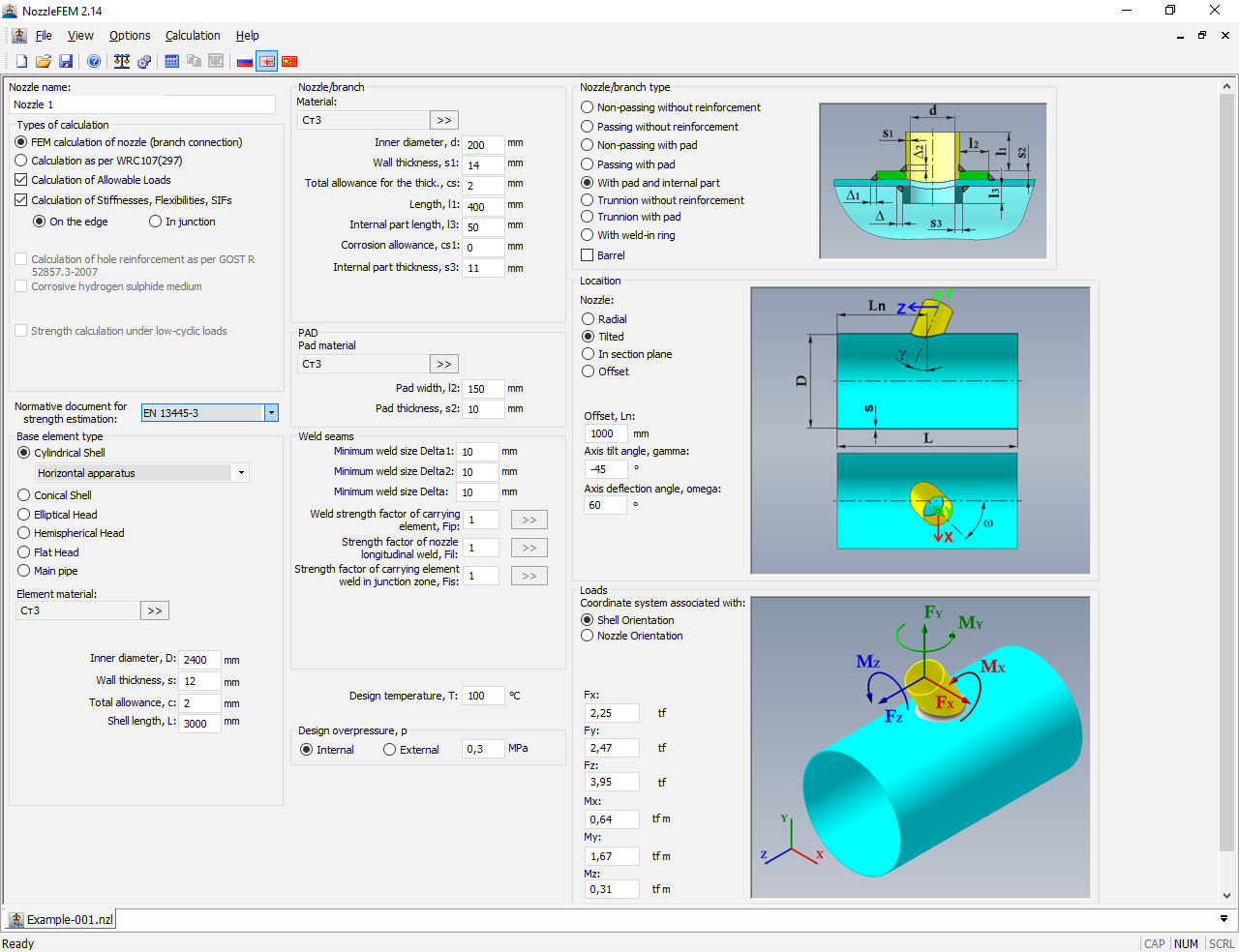

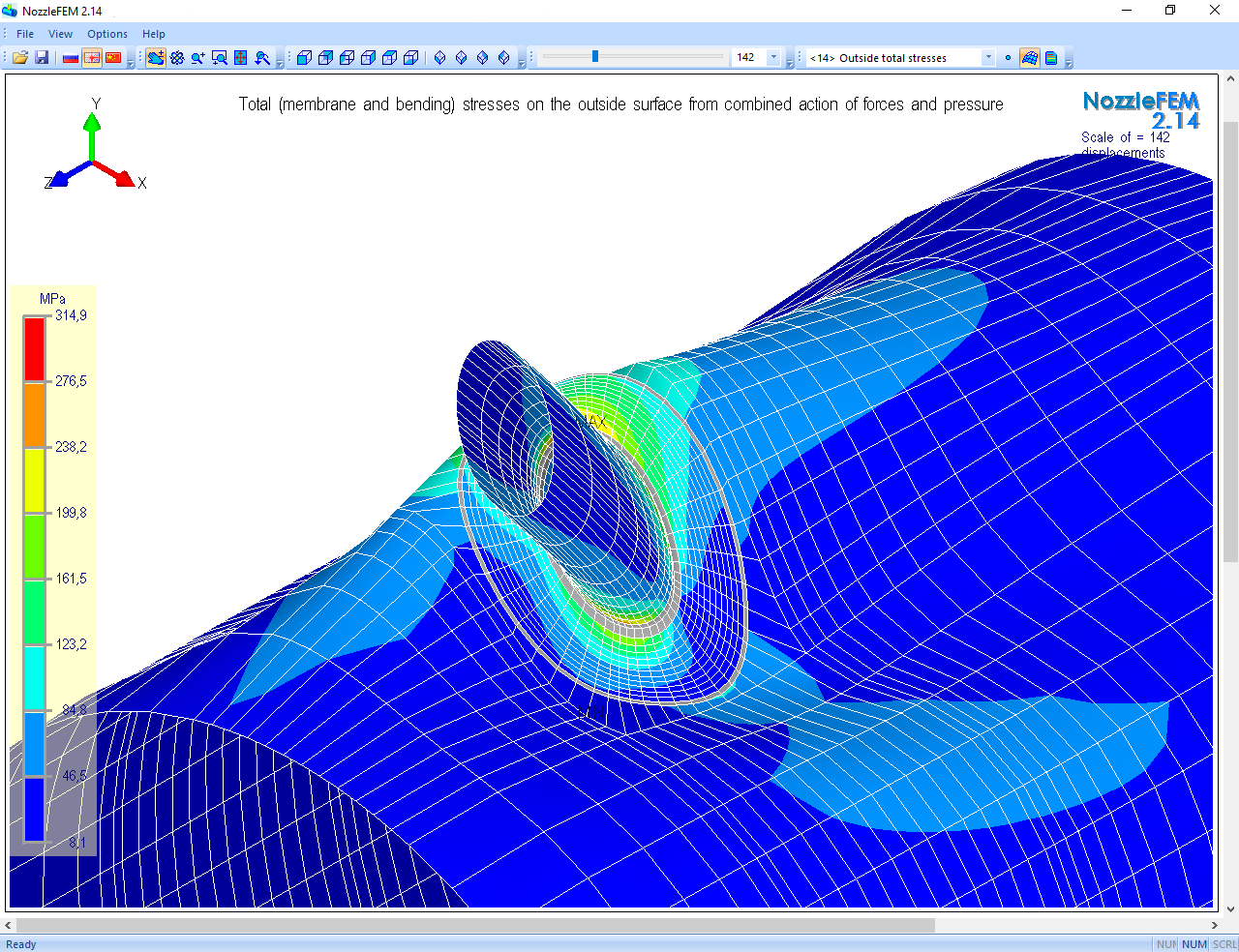

ASME B31J covers only standard straight tees and D/t less than 100. For nonstandard tees, for example, lateral and tees with D/t greater than 100 Nozzle-FEM software can be used. It can calculate SIF and k-factors which can be used in START-PROF software using a nonstandard tee.

In the next version 4.84, the NOZZLE-FEM software will be embedded into START-PROF and allow to calculate using FEM methods SIF and k-factors for tees. Also, embedded NOZZLE-FEM will allow us to calculate of nozzle flexibility and check nozzle stresses using FEM.

Dear Alex,

Thanks for this very enlighting article. Although if I may, I have a question to place.

The result of this change in stiffness which appears in the analysis by using B31J, usually results in a more flexible piping system where in the majority of the cases is what we want. Unfortunately though, there are cases where this flexibility might become a double-bladed knife. From my experience there are many times when I run my analysis and didn’t have any overstresses but when I run B31J I suddenly had. Therefore, my question is: which results should we consider when it comes to interface equipment loads, check overstresses etc. In other word is there anything (B31.3 Code?) that determines if the analysis should mandatorily be with B31J or not?

Thanks in advance,

Nelu

Dear Nelu,

Yes, using of additional ASME B31J flexibilities can sometimes increase the stresses and support loads in following situations:

1. when we analyze the system for weight and other primary loads, because more flexible system usually have a greater sustained and occasional stresses and support loads

2. when we have a nonlinear system, sometimes nonlinear behavior of supports (gaps, single-directional restraints) may lead to different results, even for secondary loads (thermal expansion, support movements, cold spring)

Actually, to ensure the safety of the piping system we should analyze all possible situations and use we worst case. For example analyze with flexibilities and without it. But there a lot of other inaccuracies in our model: the real friction factors have a range of values, Young mofulus “E” also have a range of values +-20%, real gaps after installation are unknown, and even geometry of the piping system model slightly differ from reality. To consider this we have a safety factors built-in into the code (Yield stress divided by 1.5, tensile strength divided by 3.0, etc.).

But the most important thing is that now using of ASME B31J is mandatory in the new editiin of ASME B31.1-2020 and ASME B31.3-2020. Please refer to this article: https://whatispiping.com/asme-b31-3-2020-vs-2018/

ASME B31.1-2020 already implemented into the latest version of PASS/START-PROF and B31.3-2020 included into the version 4.86 (not released yet)

Thank you for this article. Just that I seem list in most of the terms used which invariably has made to understand that I need more improvement in my specialty. Your article is highly educative. Once again,thank you for the good work.

Although B31J SIF’s can be applied to EN13480 code in the software, is it explicitly permitted to do so by the EN code itself?.