Pipe reducers are vital components in piping systems. At its core, a pipe reducer is a type of pipe fitting designed to connect two pipes with different diameters. In other words, it enables the transition from a larger pipe size to a smaller one or vice versa. In this article, we’ll introduce pipe reducers, explaining their fundamental role in piping systems, their types, materials, applications, and dimensions.

What is a Pipe Reducer?

A pipe reducer is a type of pipe fitting that reduces the nominal bore from a bigger inner diameter to a smaller inner diameter. Piping and Pipeline Systems are not of uniform size and there is a requirement to reduce or expand the lines depending on process requirements, hydraulic criteria, or availability of material. Here comes the importance of a special pipe fitting called Pipe Reducers or Pipe Expanders.

Pipe reducers are manufactured following the ASME B16.9, DIN2615, JIS B2312, and ASME B16.11 standards and are highly reliable and compact components. Pipe reducers are usually made by a forging method known as the “outer dia method”.

Types of Pipe Reducers

Reducers in piping can be classified depending on various parameters as mentioned below:

- Pipe Reducer Types Based on Construction Geometry

- Types of Piping Reducers Based on End Connection

- Pipe Reducer Categories Based on the Material of Construction

1. Types of Piping Reducers based on Construction Geometry

Pipe Reducers are one of the most extensively used fittings in the piping industry to reduce or expand the size of the straight part of the run pipe. Basically, there are two types of pipe reducers depending on the construction geometry:

- Concentric reducers and

- Eccentric reducers.

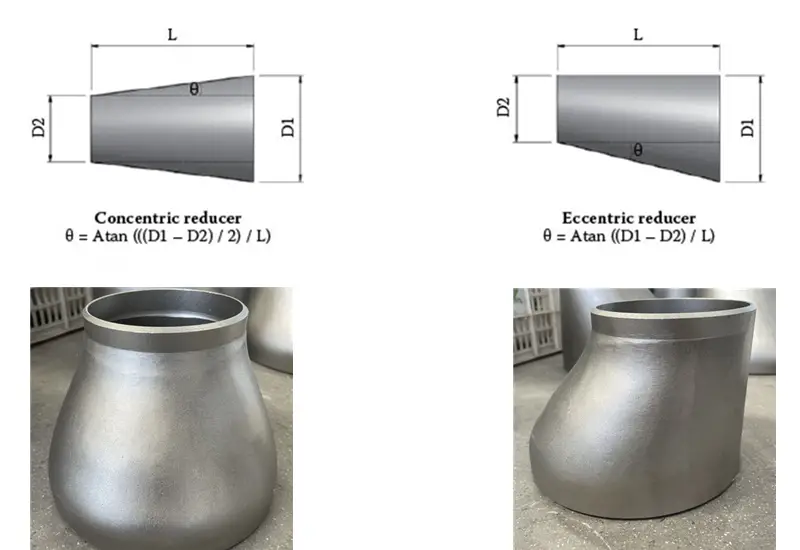

Concentric Reducers

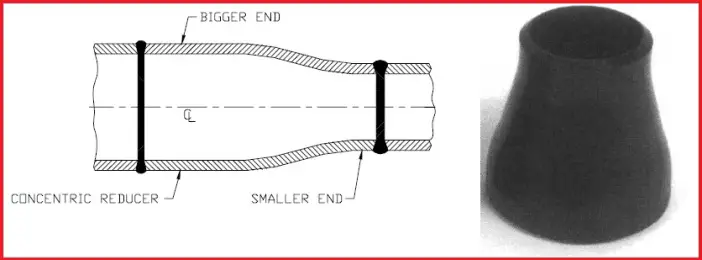

As shown in Fig. 1, In concentric reducers the area reduction is concentric and the centerline of the pipe on a bigger end and smaller end remains the same. These styles are normally used for vertical lines. So in concentric reducers, the pipe axis remains the same. Reducers are reversible and can be used in any direction.

In Concentric Reducer, the size reduction from a larger to a smaller size is uniform at a constant rate over a specified length. A symmetry is maintained around the fitting keeping the same centreline. Joining pipe or tube sections of different diameters on the same centreline axis is made possible by using concentric reducers.

Eccentric Reducers

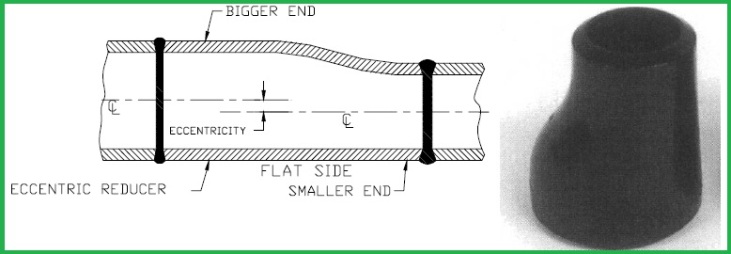

As shown in Fig. 2, in eccentric reducer there is an offset between the center lines of the bigger end and the centerline of the smaller end. This offset or eccentricity will maintain a flat side either on top or on the bottom side.

In an Eccentric Reducer, the reduction in the pipe size is achieved at a constant rate but maintains one side of the fitting horizontally. The use of eccentric reducers is also reversible and can be used as eccentric expanders. Eccentric reducers are not symmetrical about their centerlines.

This offset or eccentricity can easily be found by the following equation:

Eccentricity=(Bigger end ID-Smaller end ID)/2

Eccentric Reducer Installation

While using an eccentric reducer, the user has the option of orienting the flat side. Usually, for horizontal lines, eccentric pipe reducers are oriented with either the flat side up or down, and the same with deviation is mentioned in isometric.

Specific Uses of Eccentric Reducers

Normally eccentric reducers with the flat side down are preferred for the following cases on horizontal lines:

- On Sleepers and Piperacks: To maintain the same BOP (Bottom of Pipe) for piping supports.

- On lines requiring gravity flow

- On the pump suction line which handles slurry.

- Control valve station: An eccentric reducer with a flat side down is required to get a constant flow through the control valve with less flow disruptions.

In horizontal gas, steam, or vapor piping, eccentric reducers are required to be installed with a flat side down, which allows condensed water or fluid to drain at low points.

Pump Suction Piping Reducer

Eccentric reducers with the flat side up are used for all pump suction lines (excluding pump handling slurry) on horizontal lines. This way one can avoid air getting trapped inside the pipeline during initial venting through the pump casing and will help in avoiding Cavitation.

However, the pipe reducers used on discharge lines are concentric type.

2. Types of Piping Reducers based on End Connection

Depending on the end connections of this fitting with a straight pipe, reducers are grouped as follows:

Butt-welded pipe reducers

The applicable pressure rating and dimensional and material standards for butt-welding reducers are the same as those applicable to butt-welding elbows.

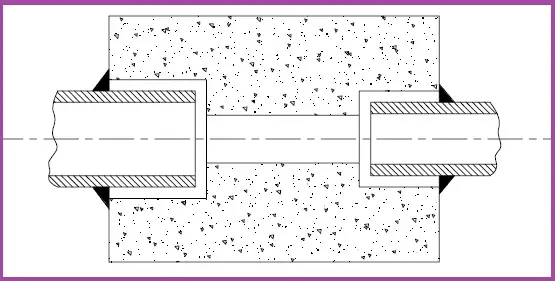

Socket welded pipe reducers

As shown in Fig. 3, such reducers are available in concentric type only and in the form of pipe coupling with one end socket to fit larger diameter pipe and another end socket to fit smaller diameter pipe. Standards are the same as those applicable to socket welding pipe elbows.

Screwed piping reducers

Available only in the concentric type and are in the form of coupling having one end to fit bigger pipe and another end to fit smaller pipe. ASME B16.11 is an applicable dimensional standard. Material standards, including pressure ratings, are the same as those of screwed elbows.

Flanged pipe reducers

Their pressure rating, use, material, and dimensional standards are the same as those applicable to flanged elbows. Regardless of reduction, their face-to-face dimensions are governed by the larger pipe size.

3. Pipe Reducer Categories Based on the Material of Construction

Depending on the pipe reducer material of construction, there are two types of piping reducers:

- Metallic Pipe Reducers, and

- Non-metallic Pipe Reducers

The common materials used for the construction of such pipe reducers are explained below.

Materials of Pipe Reducers

Pipe reducers are made of various materials like Carbon Steel, Alloy, Stainless steel, and many more non-ferrous materials. As compared to the Stainless Steel Reducer, Carbon Steel Reducer possesses higher strength, high-pressure resistance, and wear resistance, but this can be easily corroded.

- Carbon Steel material standards and grades used for pipe reducers are ASTM A234 WPB, A420 WPL6, MSS-SP-75, etc

- Stainless Steel Pipe Reducer material grades are: ASTM A403 WP 304, 304L, A403, 316, 316L, 317, 317L, 321, 310 and 904L, etc.

- Alloy Steel Pipe Reducer material grades include A234 WP1, WP5, WP9, WP11, WP22, WP91, etc.

- Duplex Steel: ASTM A 815 UNS NO S31803, S32205

- Nickel Alloy: ASTM/ASME SB 336 UNS 2200 (NICKEL 200), UNS 8020 (ALLOY 20 / 20 CB 3, UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8825 INCONEL (825), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601).

- Copper Pipe Reducers

- Brass Pipe Reducers

- Non-Metallic Pipe Reducers

- PVC Piping Reducers

- Rubber Pipe Reducers

- HDPE Pipe Reducers

- Plastic Pipe Reducers

- GRP/FRP Piping Reducers, etc

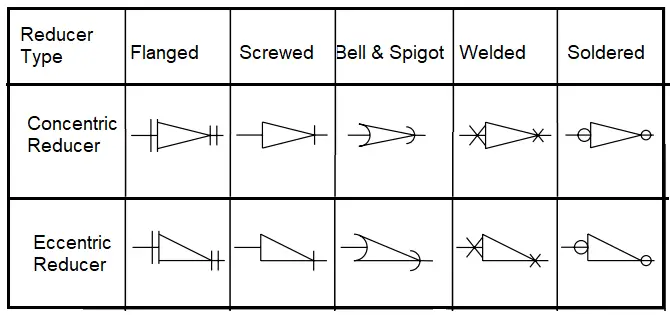

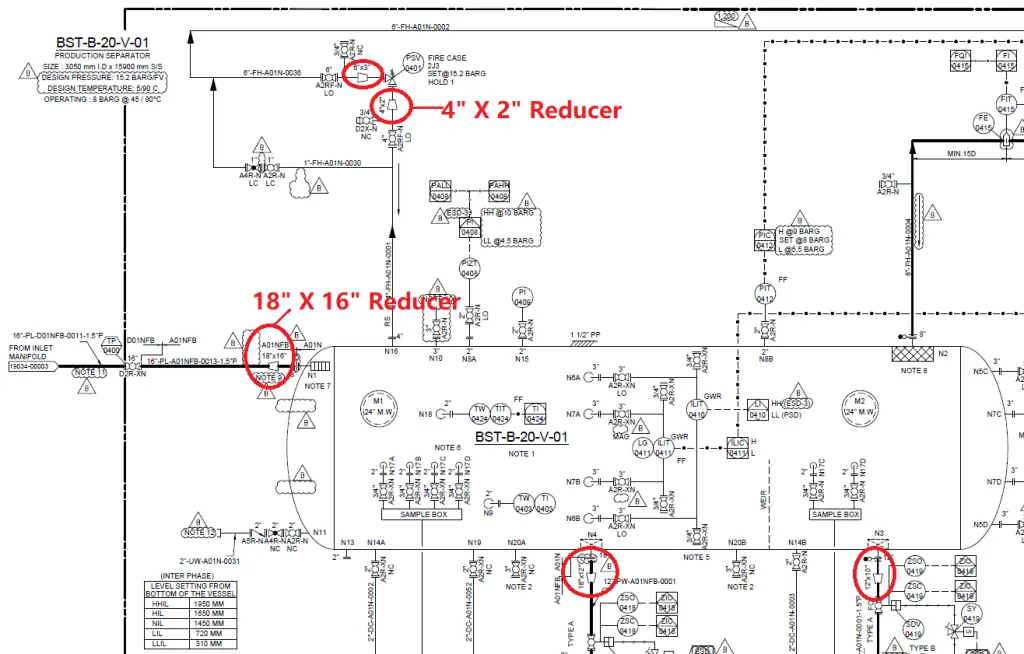

Piping Reducer Symbols

Reducer symbols help in the proper identification of the exact pipe fitting. Fig. 5 below provides the symbols for piping reducers that are used in P&ID and Isometric drawings.

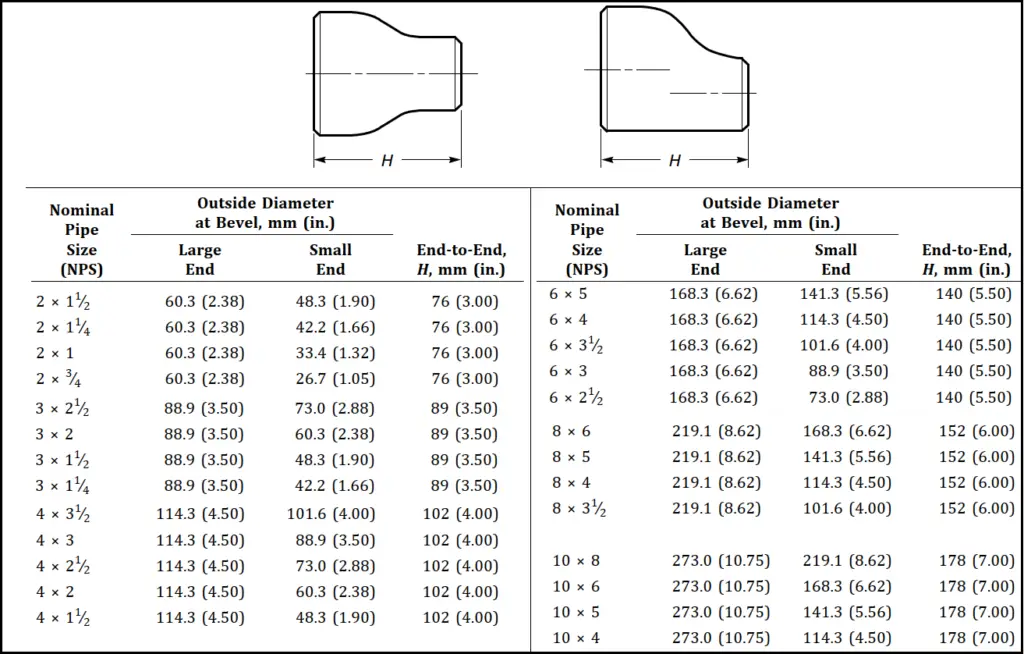

Pipe Reducer Fitting Dimension | Pipe Reducer Size Chart

The dimensions for butt welded piping reducers are provided by ASME B16.9. In Pipe Data Pro software, you can easily get the required pipe reducer dimensions. The following image provides part of the pipe reducer size chart as a reference.

When to Use a Piping Reducer

Pipe reducers are essential fittings for adapting pipes of different sizes, offering solutions for various complex scenarios. They are particularly useful when adjustments in flow rates or pressure are required within a piping system. For instance, in systems where hydraulic conditions necessitate flow management, reducers play a crucial role in controlling these parameters. It is important to consider how a pipe reducer will impact the overall system, as it can affect both flow dynamics and pressure levels.

Here are some common scenarios where a reducer is appropriate:

- Flow Rate Management: To adjust the flow rate by connecting a larger diameter pipe to a smaller one, which can be essential for controlling the speed and volume of the fluid or gas in the system.

- Pressure Control: When reducing the pipe diameter, the velocity of the fluid increases, which can help manage pressure changes in the system. This is useful for optimizing system performance and preventing pressure loss.

- System Design and Integration: To connect pipes of varying sizes in a complex system. For example, a large main pipe might need to connect to smaller branch pipes or equipment with different inlet or outlet sizes.

- Space Constraints: In situations where space is limited, a reducer can facilitate the transition between different pipe sizes without requiring additional space for larger fittings or equipment.

- Component Compatibility: When existing equipment or components have different connection sizes, a reducer helps integrate them into the piping system without needing to replace or modify the equipment.

The application of Pipe reducers is mentioned in the P&ID and accordingly, they are selected as per the sizes mentioned. As you can see in Fig. 7, the requirements of Piping Reducers are clearly specified.

Uses of Piping Reducers

Piping reducers or expanders are widely used in the piping, pipeline, and plumbing industries to change pipe size from a larger to a smaller diameter. Common industries where pipe reducers find extensive applications are:

- Chemical and Petrochemical Industry

- Water Treatment

- HVAC Systems

- Food and Beverage Industry

- Mining and Construction

- Oil and Gas Industries

- Pharmaceutical Industry

- Wastewater

- Shipbuilding Industry, etc

In general, horizontal liquid reducers are always eccentric, with the flat side on top. This design helps prevent air bubbles from building up in the system. In pipe racks, the flat side is on the bottom to keep the pipe’s bottom position consistent and supported. Eccentric reducers are used on the suction side of pumps to avoid air accumulation, which could cause pump stalls or cavitation. Horizontal gas reducers are always eccentric, with the flat side on the bottom. This allows condensed water or oil to drain from the low points.

Reducers in vertical pipes are usually concentric unless the layout requires a different design.

Piping Reducer Ordering Information

The following information should be supplied to the vendor while placing an order for pipe reducers.

- Pipe Size and Outer diameter

- Governing standard (ASME B16.9, GB, HG, HGJ, SH, SY, DL, AN, SI, JIS, or DIN).

- End connection (Welded/Flanged, etc.)

- Distance from end to end.

- Material of construction.

- Seamless or welded construction.

- Fluid service and Corrosion allowance

- Pressure class

Differences between Concentric and Eccentric Reducers | Eccentric vs Concentric Reducers

A concentric reducer and an eccentric reducer are two different types of pipe reducers that are used to connect pipes of different sizes. The main differences between them are in their shapes and how they are used.

A concentric reducer is a type of pipe reducer that has a conical shape with a symmetrical centerline. It is designed to reduce the pipe’s diameter uniformly and is commonly used in horizontal piping systems where there is no need to maintain the same elevation. With a concentric reducer, the centerline of the larger end of the reducer coincides with the centerline of the smaller end, which means that the fluid flow direction remains unchanged.

On the other hand, an eccentric reducer is a type of pipe reducer that has an asymmetrical centerline. It is designed to reduce the pipe’s diameter and shift the centerline of the pipe at the same time, which means that it is commonly used in horizontal piping systems where there is a need to maintain a constant fluid level. With an eccentric reducer, the centerline of the larger end of the reducer is offset from the centerline of the smaller end, which means that the fluid flow direction changes.

The major differences between an eccentric reducer and a concentric reducer can be summarized as follows:

| Aspect | Concentric Reducer | Eccentric Reducer |

|---|---|---|

| Shape | The central axis remains aligned during the transition. | The central axis is offset, with one side flat. |

| Pipe Alignment | Aligns the centerline of the larger and smaller pipes. Concentric reducers provide an in-line conical transition between pressurized pipes of differing diameters. Thus, concentric reducers connect pipes of unequal size but have a common centerline. The same fitting can be used in reverse as a concentric expander. | Offsets the centerline of the larger and smaller pipes. An eccentric pipe reducer fitting is manufactured with the smaller outlet off-center to the larger end, which allows it to align with only one side of the inlet. The same fitting can be used in reverse as an eccentric expander. |

| Flow Characteristics | More suitable for vertical pipe systems | Better for horizontal pipe systems to prevent air pockets |

| Installation | Generally easier to install in vertical pipes | Often used in horizontal applications or where a smooth flow transition is needed |

| Application | Common in systems where the alignment of the pipes is critical | Preferred in systems where air or gas pockets may form |

| Cost | Typically less expensive | May be more expensive due to the complex design |

In summary, the main differences between concentric and eccentric reducers are their shapes and their application. A concentric reducer has a symmetrical centerline and is used to reduce the diameter of the pipe uniformly, while an eccentric reducer has an asymmetrical centerline and is used to shift the centerline of the pipe while reducing the diameter.

Pipe Reducer vs Pipe Expander: What are the Differences?

A pipe reducer and a pipe expander are both used to transition between pipes of different diameters, but they serve opposite functions. A pipe reducer decreases the diameter of a pipe, typically featuring a conical or tapered shape that narrows from a larger to a smaller end, and is used to manage flow rates and pressure changes. In contrast, a pipe expander increases the diameter, often with a bell-shaped or tapered design that widens from a smaller to a larger end, facilitating the transition to larger pipes and accommodating varying flow rates.

While reducers help adapt systems to smaller pipe sizes, expanders are employed to upgrade or accommodate larger pipe sizes, and their installation requires careful alignment to ensure smooth flow and system efficiency. In general, it is related to the fluid flow direction. If towards the fluid flow the outlet size increases, it is called a pipe expander. Again when towards the fluid flow direction, if the pipe size decreases it is called a piping reducer.

Usually by using a pipe reducer the fluid velocity is increased and by using a piping expander the fluid velocity is reduced.

Some more related resources for you.

Piping Elbows vs Bends: A useful literature for piping engineers

“Pipe Coupling”-A short Introduction for the piping professionals

Different Types of Hose Couplings

A Literature on Piping Nipples for piping and plumbing industry

Thanks for the very good article.

I wanted to know about the basic difference between Swage nipple and Reducers.

Thanks for the article

In addition, it must say that standard ASME B16.9 used for butt welding reducers and B16.11 for forged steel, socket welding and threaded ones.

In selection of the materials, reducers and other components must made of material having at least the similar allowance stress of the pipe and must have a pressure retention strength of at least 87.5% of the wall thickness of the matching piping.

Cheers

Furthermore, when the reducer size dropped less that 2″, it will be called Swage nipple and it is covered by MSS SP 95. connections are socket welding and threaded.

Thanks for the sharing.,

I wonder., is it permissible to install top flat reducer at the pump discharge side?