Isolation joints provide an electrical break between pipeline sections of the same or different pipelines, or between pipeline sections and neighboring structures. This limits the possibility of electrical bridging across the joint. The Purpose of the isolation joint is to prevent detrimental electro-chemical interaction and improve the effectiveness of the cathodic protection system. Isolating joints are also used to ensure effective current distribution for a cathodic protection system. They are also known as Isolating Joints or Insulating Joints.

A monolithic isolation joint (MIJ) is a single-piece electrical isolation block that is widely used in pipeline systems to reduce corrosion by the methods of cathodic protection. Monolithic isolation joints are an integral part of the pipeline system and provide satisfactory long-term integrity. All the components of the MIJ system are fully encased in forged steel bodies.

Isolating Joint Functional Requirements

- The isolation joint shall be suitable for Pigging Operation.

- Slip-on Flanges shall not be used.

- The isolation joints shall be able to withstand the operating conditions stated in the requisition sheets. Where the operating conditions are not stated, the following operating conditions shall apply.

- Installation: Above-ground. Pipeline isolation joints are installed in the aboveground part immediately after the aboveground-belowground transition.

- Design temperature: 82 deg C maximum & 5 deg minimum

Advantages of Monolithic Isolation Joints

For buried pipeline applications, monolithic isolation joints are more common. External attacks from extreme environments and tampering are prevented by the robust steel body. In general, MIJs are installed aboveground in pipeline systems in order to limit the possibility of electrical bridging across the joint. It is intended to be girth welded between two pipeline sections.

The benefits that a monolithic isolation joint serves are:

- MIJs eliminate the source of a short circuit by removing bolts, sleeves, and washers.

- As there are no flanges, gaskets, nuts, washers, sleeves, or bolts, the requirement for field assembly is eliminated. At the same time, the chances of leakage due to improper field assembly are also removed.

- MIJ system is usually less expensive as compared to insulated gasket flange assembly.

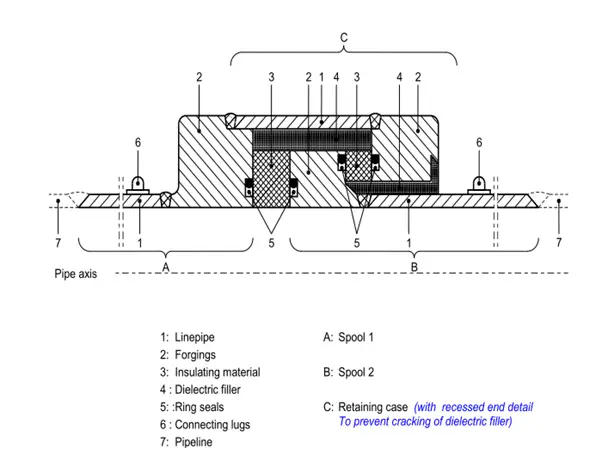

Isolation Joint Components

The isolation joint shall consist of the following components

1) Two spools, each consisting of a pipe segment with a beveled end for welding to the pipeline on one side, having a welded-on boltless flange at the other end for encapsulation into isolating and filler material.

The material used for the pipe segments shall be compatible with the pipeline material.

2) A rigid casting (retaining ring) for strength connection.

- One set of ring seals for pipeline internal pressure containment below 50 bar (g).

- A double sealing arrangement shall be specified for design pressure in excess of 50 bar (g).

3) Two terminal connecting lugs on the outer surface of each spool. Each lug shall be suitable for an M10 bolted cable connection.

Dimensional Requirements of Isolation Joint

The Internal Diameter of the Isolating Joint shall not deviate by more than +/- 2% of the nominal internal diameter of the pipeline for diameters not exceeding DN500 and +/-1.5% for nominal diameters above DN500.

The pup pieces at both ends of the isolating joint should be the same wall thickness as the pipeline.

Monolithic Isolation joints are designed to match the metallurgy and application demands of the pipeline following the specifications of the project to ensure long maintenance-free service life.

Note that, isolation joints are the weakest elements in the pipeline system and therefore, the force and moment transfer to the joint must be limited. The force and moments at the pipeline isolating joint have to be qualified against vendor-given allowable values while performing stress analysis of the specific pipeline system. The design of isolation joints can be based on Shell DEP 31.40.21.31

PLS CONFIRM THAT YOU CAN SUPPLY US 1 QTY OF 12″ INSULATION JOINT TO NIGERIA

Is requirement still alive.

Dear,

Good afternoon, my name is Carolina Panchi from the company Andessuply (Ecuador), please I need your help with the quote for the following material:

– 8 INCH MONOLITHIC ISOLATION JOINT BUTT-WELD MONOLITHIC ISOLATION JOINT, ASME B31.4, ASTM A694 F42, TO MATCH WITH PIPELINE API 5L X42, WT 0,5 INCH, DESIGN PRESSURE 3375 PSIG AT 200 °F, OPERATION PRESSURE 2100 PSIG AT 140°F (INTERNAL DIAMETER SHALL BE EQUAL TO PIPELINE INTERNAL DIAMETER TO ALLOW PIGGING ACTIVITIES) MATCHING PIPELINE API 5L X42, WT 0,5 INCH.

THE DISTANCE BETWEEN THE WELDING AND BODY OF MONOLITHIC INSULATION JOINT SHALL BE TWO DIAMETERS MINIMUM (WITHOUT INTERNAL WELDING) (Quantity: 4 EA)

– 4 INCH MONOLITHIC ISOLATION JOINT BUTT-WELD MONOLITHIC ISOLATION JOINT, ASME B31.4, ASTM A694 F52, TO MATCH WITH PIPELINE API 5L X52, WT 0,337 INCH, DESIGN PRESSURE 2100 PSIG AT 140 °F, OPERATION PRESSURE 1200 PSIG AT 140°F (INTERNAL DIAMETER SHALL BE EQUAL TO PIPELINE INTERNAL DIAMETER TO ALLOW PIGGING ACTIVITIES) MATCHING PIPELINE API 5L X52, WT 0,337 INCH.

THE DISTANCE BETWEEN THE WELDING AND BODY OF MONOLITHIC INSULATION JOINT SHALL BE TWO DIAMETERS MINIMUM (WITHOUT INTERNAL WELDING) (Quantity: 2 EA)