Iris M from RDI technologies is the first device of its kind that allows users to see – in real-time – the motion that is unseen to the human eye. This patented Motion Amplification Technique lets you see the invisible.

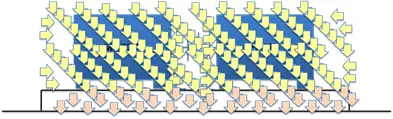

Iris M is a unique, revolutionary technology that detects subtle motion and amplifies that motion to a level visible to the naked eye. By turning every pixel in the camera into a sensor, Iris M takes millions of measurements in a fraction of a second with no physical connection to the machinery or equipment. Motion Amplification™ is a proprietary video processing algorithm that detects subtle movement and then converts that movement to a level visible to the naked eye which enhances the understanding of the components and interrelationships creating the motion.

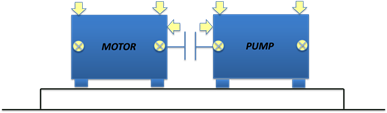

In a typical traditional data acquisition process, we have to fix the sensors at predefined locations on the machinery or equipment. The data collection is non-simultaneous and prepares a report with a detailed explanation or exception list with spectra and waveforms.

In this revolutionary technology – Iris M, data are collected by a high-speed machine-grade camera in the form of standard video. It measures the movement not visible to the naked eye by turning each pixel into a sensor that measures vibration and motion. It used patented methods and processing algorithms to extract meaningful data. The data is simultaneous and gives a report with detailed displacement and frequency spectrums.

Iris M Platform monitors critical manufacturing operations, processes, quality, piping, and structural components that affect plant reliability and productivity. It is a perfect tool for screening, fault finding, baseline or commissioning, and pre/post repairs or retrofits.

Benefits of Motion Amplifications

- Improved Safety: Totally non-contact

- Reduce unplanned downtime: Know what your “Bad Actors” are doing

- Complimentary Tool

- Diverse applications – Machines, Structures, Processes, Piping, Visual ODS

- Setup & acquire data in minutes, easy to deploy, use often as a troubleshooting tool

- Actionable information: Results are easy to see in a standard video

- Communications with facility resources are enhanced

The World’s First Non-Contact Motion Amplification Platform – Iris M